Method for treating stainless steel pickling sludge and preparing slag cement

A technology of pickling sludge and slag cement, which is applied in the field of metallurgy, can solve problems such as process pollution and sinter product quality decline, and achieve the effects of huge environmental and economic benefits, simple implementation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

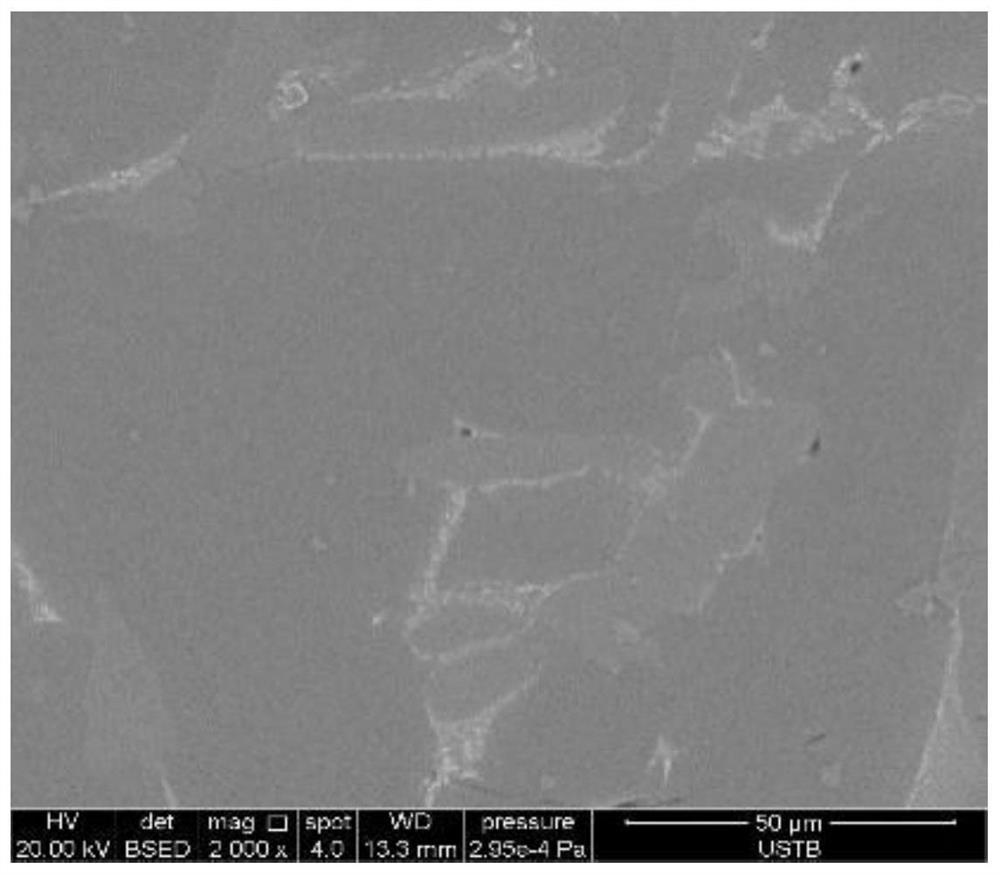

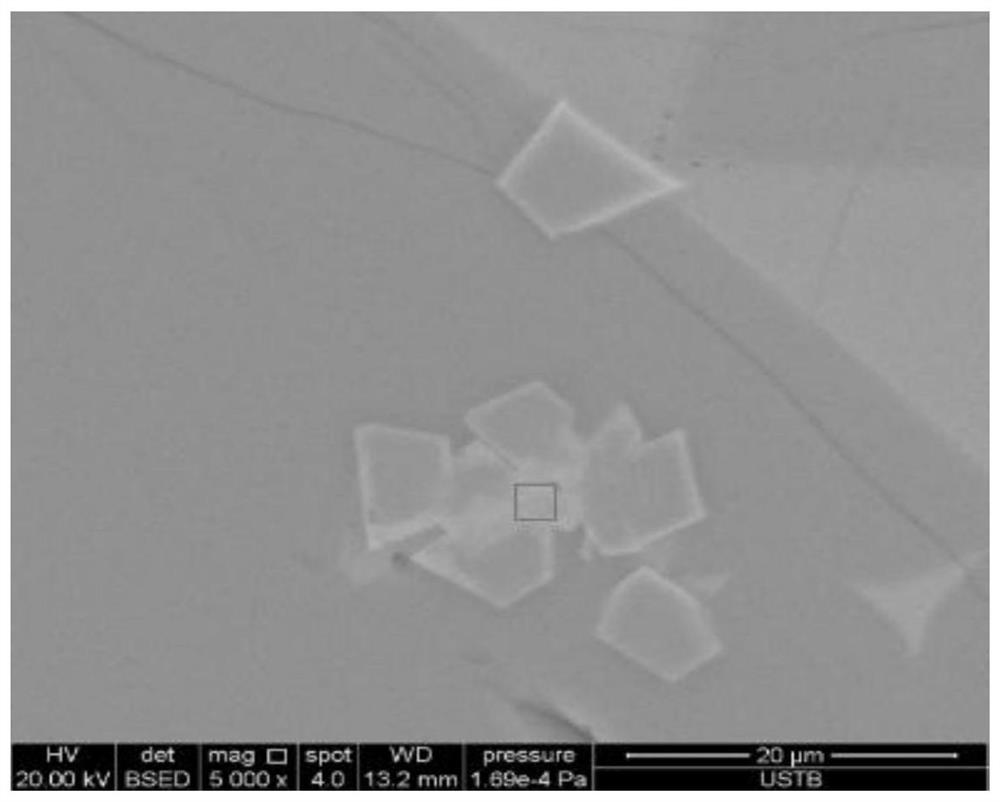

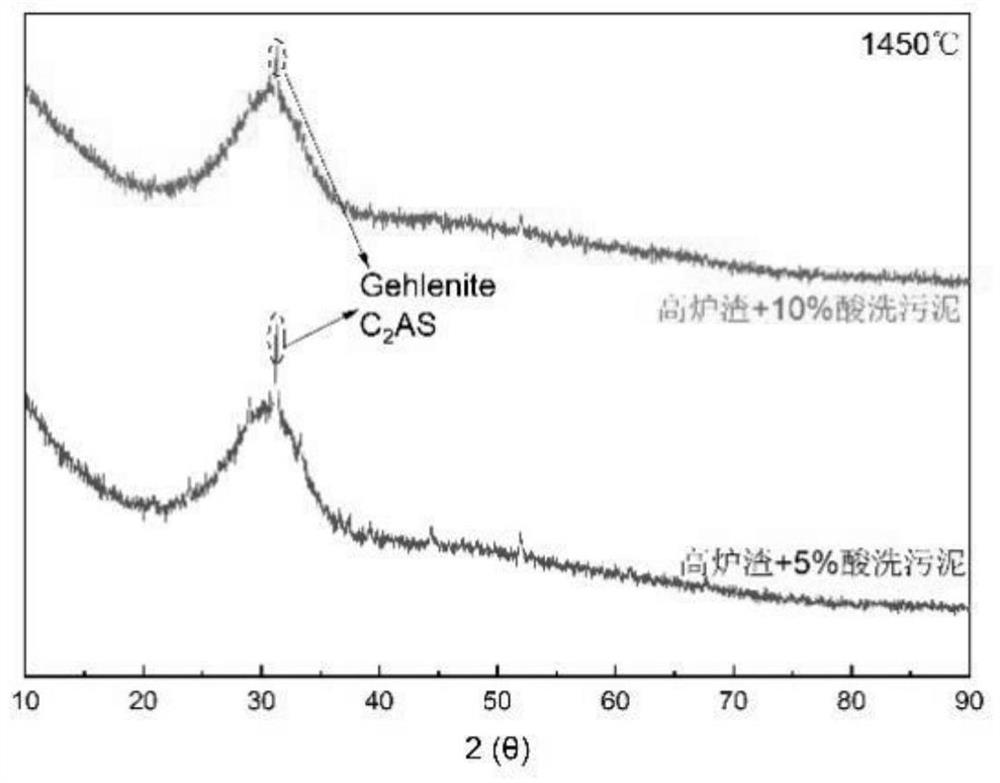

[0048] Embodiment 1 laboratory test

[0049] Dry the original stainless steel pickling sludge with a higher water content at 400°C for 2 hours to obtain a stainless steel pickling sludge with a water content of 1%, which is set aside;

[0050] The modifier is fly ash;

[0051] 10g of the stainless steel pickling sludge, 3g of modifier and 100g of blast furnace slag were mixed evenly and placed in a porcelain boat;

[0052] The porcelain boat was placed in a horizontal resistance furnace, the temperature was raised to 1450°C at a rate of 5°C / min, and the temperature was kept for 5 minutes to obtain molten slag.

[0053] Quickly pull the porcelain boat out of the high-temperature zone, and perform water quenching at a cooling rate of 400°C / min to obtain granulated slag;

[0054] The slag powder (the specific surface area is 689m 2 / kg) and Portland cement clinker in a mass ratio of 1:1 to obtain slag cement.

Embodiment 2

[0056] The preparation method is basically the same as in Example 1, except that the addition amount of the stainless steel pickling sludge is adjusted from "10g" to "5g".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com