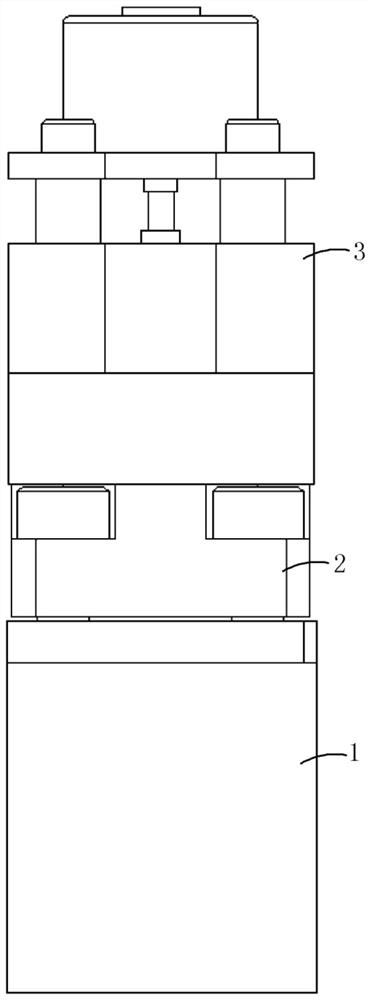

Mass flow controller and flow adjusting mechanism thereof

A technology of flow controller and flow adjustment, which is applied in the direction of valve details, valve casing structure, mechanical equipment, etc., can solve the problems of poor sealing effect, poor applicability, low production capacity, etc., to reduce internal leakage rate, improve use efficiency, improve The effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

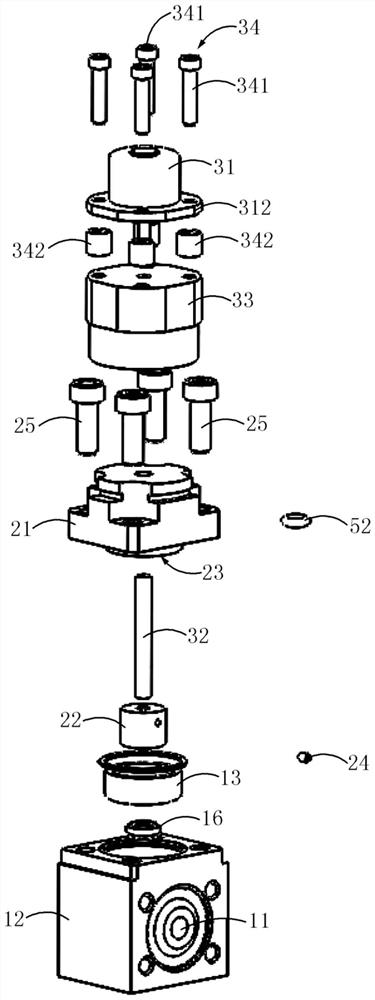

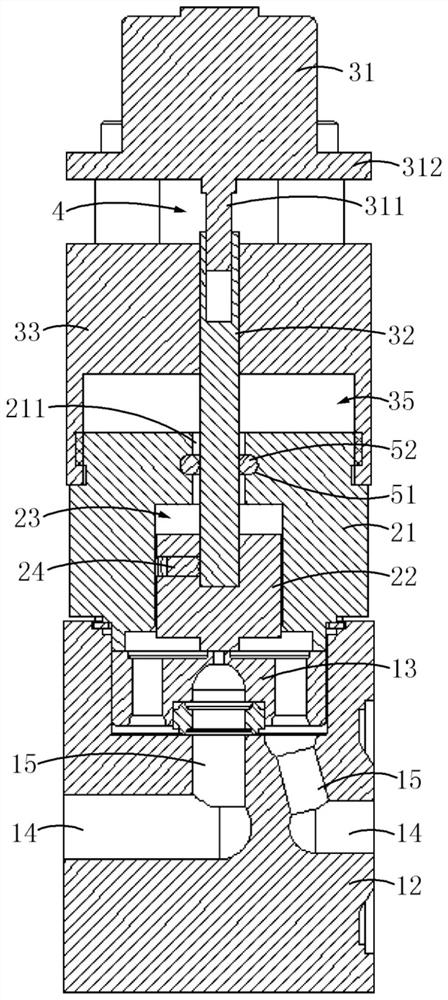

[0026] The present application will be described in detail below, and examples of the embodiments of the present application are illustrated in the drawings, in which the same or similar reference numerals represent the same or similar components or components having the same or similar functions. Further, it is omitted if the detailed description of the known techniques is unnecessary to the features of the present application. The following is exemplary, and is intended to explain the present application by referring to the embodiments described with reference to the accompanying drawings.

[0027] Those skilled in the art will appreciate that all terms (including technical terms and scientific terms) used herein, unless otherwise defined. It should also be understood that those terms defined in a general dictionary should be understood to have meaningful meaning with the meaning of the context of the prior art, and unless it is a particular definition as it is, it will not be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com