Open-close type annular PCB type pulse large current sensor

An open-close, high-current technology, used in instruments, measuring electrical variables, measuring devices, etc., can solve the problem that the Rogowski coil cannot be installed with a compact pulse power supply, etc., to achieve good electromagnetic shielding effect, reliable product structure, and reduce rapid changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

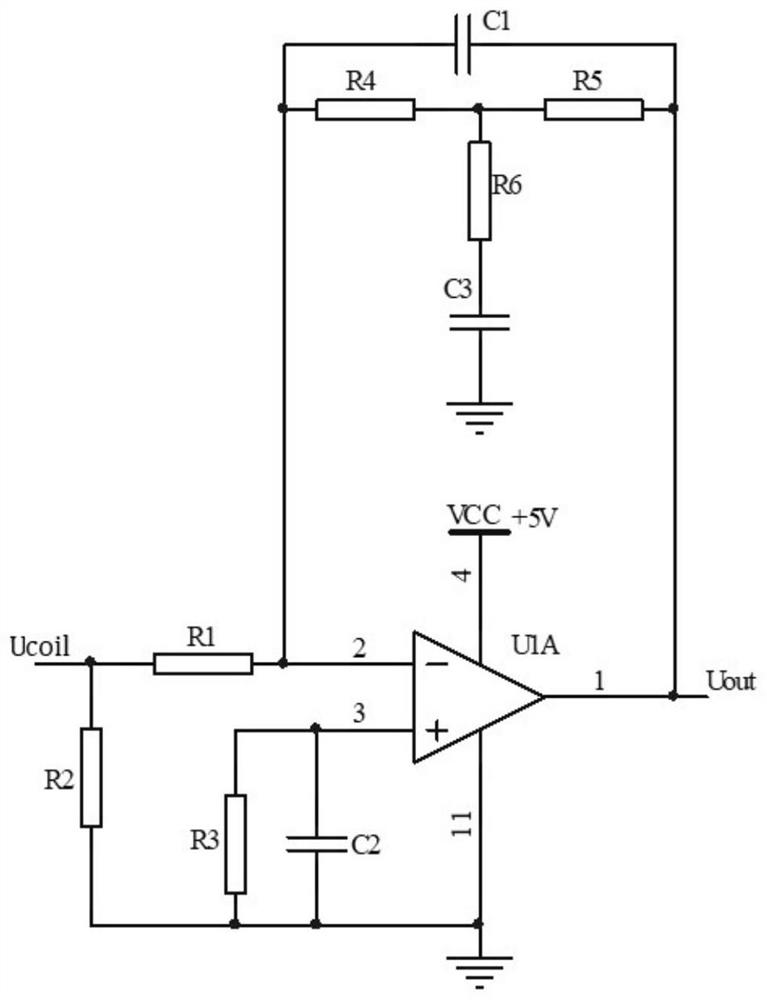

[0035] The invention provides a split ring current sensor based on a multilayer PCB magnetic induction coil, especially for measuring millisecond-level high-power pulse current, and is a current sensor based on the law of ampere's loop and the law of electromagnetic induction. The present invention will be described in further detail below in conjunction with the accompanying drawings.

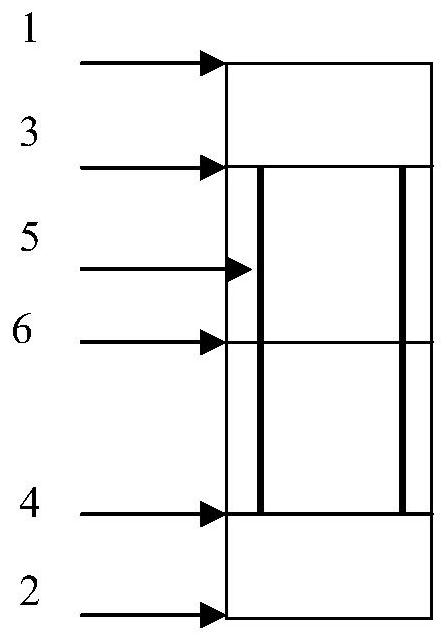

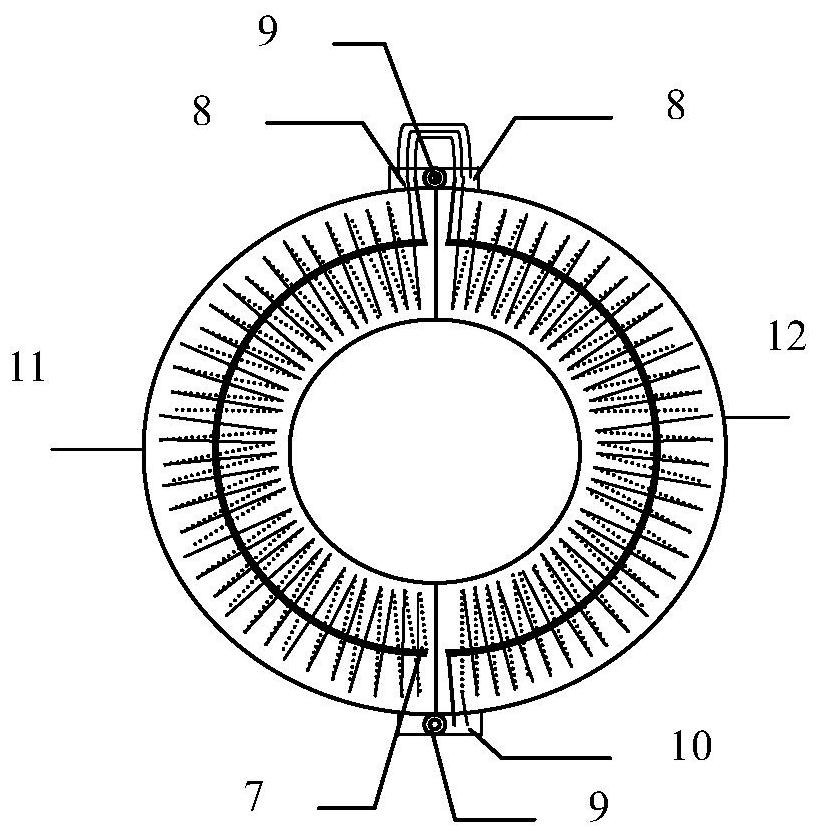

[0036] A split ring PCB type pulse high current sensor adopts the splicing design of two semi-ring multi-layer PCB boards. figure 1 The illustrated embodiment is a structural schematic diagram of a longitudinal section of a 6-layer PCB board of the PCB type pulse high current sensor, figure 2 It is a schematic diagram of wiring and assembly of the coil layer of the PCB board.

[0037] In order to facilitate disassembly and assembly, the PCB-type magnetic induction coil adopts a double semi-circular open-close design, see figure 2 As shown in 11 and 12, the semi-annular PCB board referred t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com