Laser fragmentation method for solid material

A solid material and laser technology, applied in the direction of electric solid devices, laser welding equipment, semiconductor devices, etc., can solve the problems of high production cost, low production efficiency, complex devices, etc., to improve processing efficiency, increase production efficiency, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

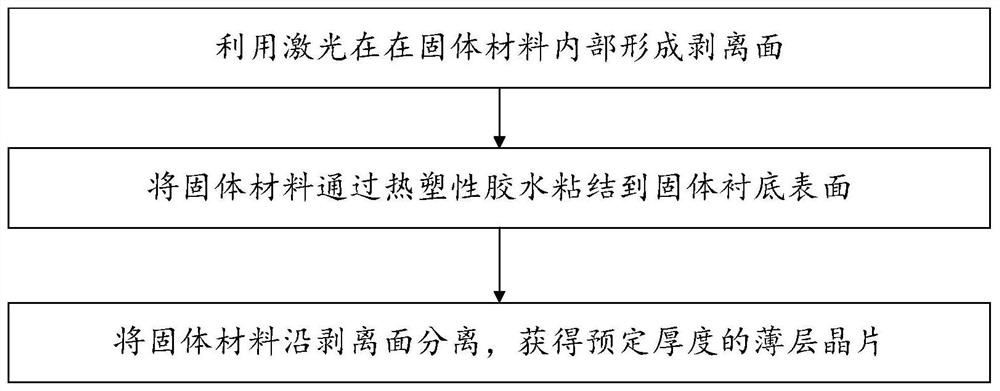

[0046] A laser slicing method for solid materials, such as figure 1 shown, including the following steps:

[0047] Use laser to form a peeling surface inside the solid material;

[0048] Bond the solid material to the surface of the solid substrate with thermoplastic glue;

[0049] The solid material is separated along the peeling surface to obtain a thin-layer wafer with a predetermined thickness.

[0050] The laser slicing method for solid materials of the present invention uses laser to form a peeling surface inside the solid material to be separated to ensure the consistency of the thickness of the thin-layer wafer, and uses thermoplastic glue and solid substrate to assist peeling, the peeling process is simple and reliable, and The obtained thin-layer wafer after peeling is easy to separate from the solid substrate, which reduces the production cost and improves the production efficiency.

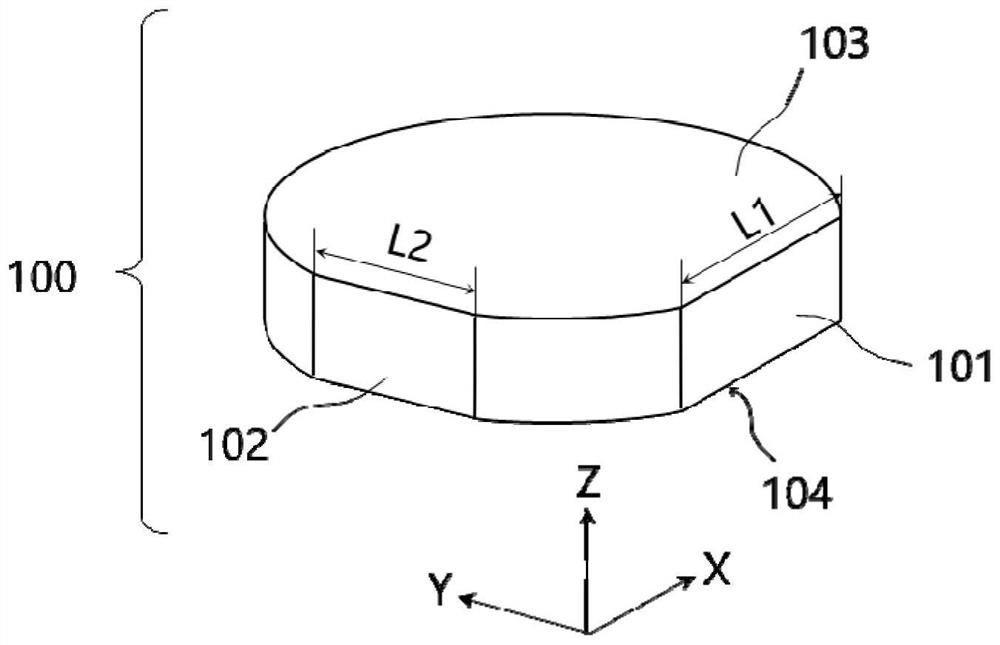

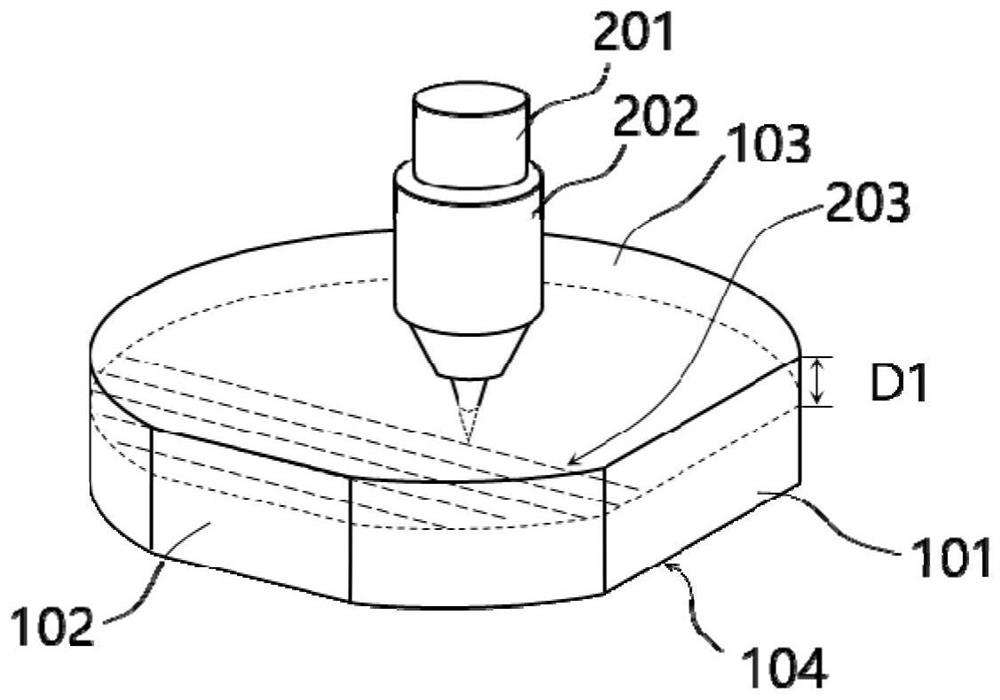

[0051] The solid material is a columnar crystal ingot, the solid material inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com