Waste incineration slag treatment system and method

A waste incineration slag and processing system technology, which is applied in the field of metal recycling, can solve the problems of low metal recovery rate and inability to recover multiple metals at the same time, and achieve the effects of high debris removal rate, remarkable economic effect, and efficient energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

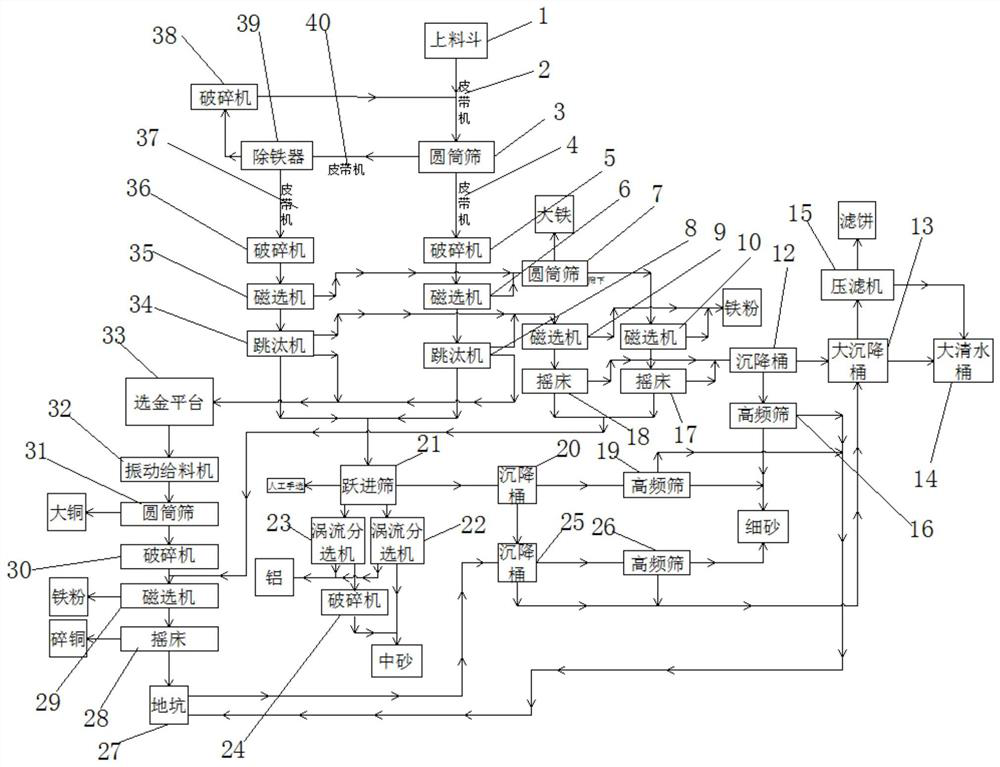

[0022] like figure 1 As shown, this embodiment discloses a waste incineration slag treatment system and method, including an iron recovery system, a copper recovery system, an aluminum recovery system, a sand making system, and a tailings treatment system;

[0023] The iron recovery system includes an upper hopper 1, a first cylindrical screen 3, a second cylindrical screen 7, a first crusher 5, a second crusher 38, a third crusher 36, a first magnetic separator 6, a second Two magnetic separators 35, the third magnetic separator 9, the fourth magnetic separator 10, the fifth magnetic separator 29, the first jig 8, the second jig 34, the first iron remover 39...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com