Method for preparing marking pattern on polyimide surface based on femtosecond laser processing

A femtosecond laser processing and polyimide technology, which is used in metal processing equipment, laser welding equipment, welding equipment and other directions to achieve good processing effects and clear display effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

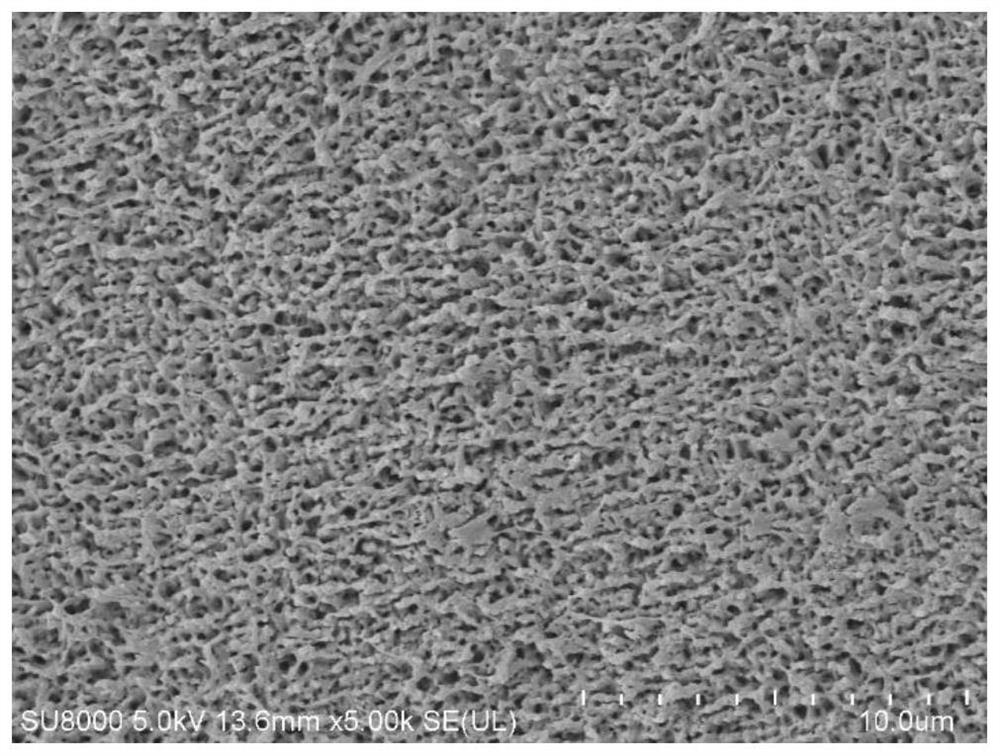

[0027] Embodiment 1, a method for preparing a marking pattern based on femtosecond laser processing polyimide surface, comprising the following steps:

[0028] 1) A polyimide film with a thickness of 125 μm is used as a sample;

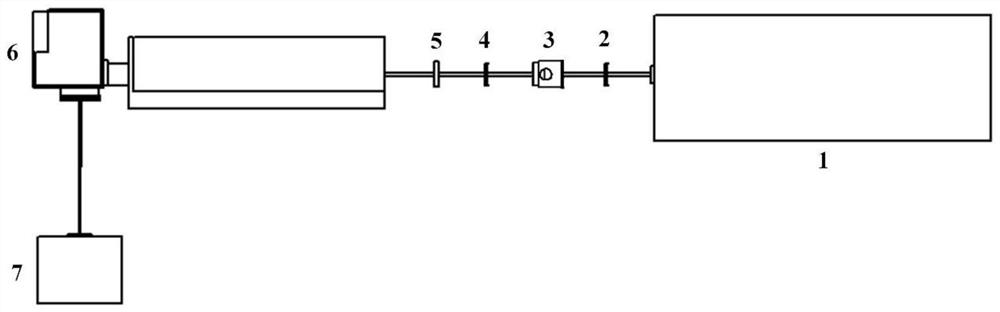

[0029] 2) Build the optical path, refer to figure 1 , the output light of the femtosecond laser 1 sequentially passes through the first half-wave plate 2, the Glan Taylor prism 3, the second half-wave plate 4 and the pinhole diaphragm 5, and finally passes through the two-axis scanning galvanometer system 6 to focus on the scissor lift table 7, the femtosecond laser 1 and the two-axis scanning galvanometer system 6 are connected to the computer;

[0030] 3) Using a computer to adjust the output laser of the femtosecond laser 1, the laser wavelength is 800nm, the pulse width is 120fs, the repetition frequency is 1kHz, and the maximum single pulse energy is 5mJ;

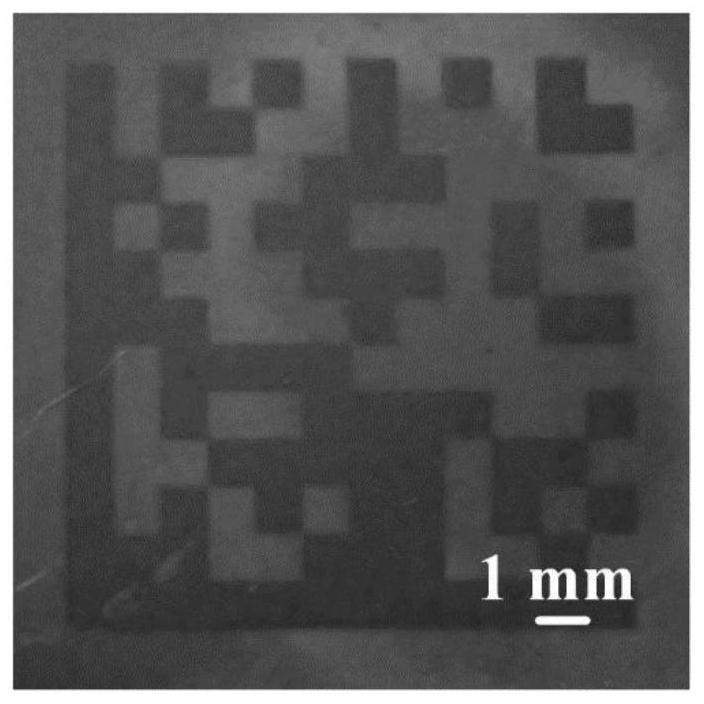

[0031] 4) Fix the sample on the processing station 7 of the scissor lift table, adjust t...

Embodiment 2

[0034] Embodiment 2, a method for preparing a marking pattern based on femtosecond laser processing polyimide surface, comprising the following steps:

[0035] 1) A polyimide film with a thickness of 125 μm is used as a sample;

[0036] 2) Build the optical path, refer to figure 1 , the output light of the femtosecond laser 1 sequentially passes through the first half-wave plate 2, the Glan Taylor prism 3, the second half-wave plate 4 and the pinhole diaphragm 5, and finally passes through the two-axis scanning galvanometer system 6 to focus on the scissor lift table 7, the femtosecond laser 1 and the two-axis scanning galvanometer system 6 are connected to the computer;

[0037] 3) Using a computer to adjust the output laser of the femtosecond laser 1, the laser wavelength is 800nm, the pulse width is 120fs, the repetition frequency is 1kHz, and the maximum single pulse energy is 5mJ;

[0038] 4) Fix the sample on the processing station 7 of the scissor lift table, adjust t...

Embodiment 3

[0043]Embodiment 3, change the traditional marking pattern parameter into laser energy 100mW in step 4) in embodiment 1 and embodiment 2, scanning speed 25mm / s, scanning distance 5 μ m; Color code pattern parameter is changed into: laser energy 100mW, black The scanning speed is 25mm / s when it is yellow or purple, and the scanning speed is 125mm / s when it is yellow or purple, and the scanning distance is 5μm.

[0044] The effect of this embodiment is similar to that of Embodiment 1 and Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com