Preparation method of jack fruit wine

A technology of jackfruit fruit and jackfruit, which is applied in the field of preparation of jackfruit wine, can solve the problems of fermentation product pollution, contact between fermented product and outside air, waste of fermentation raw materials, etc., and achieve the effect of avoiding external pollution and improving fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

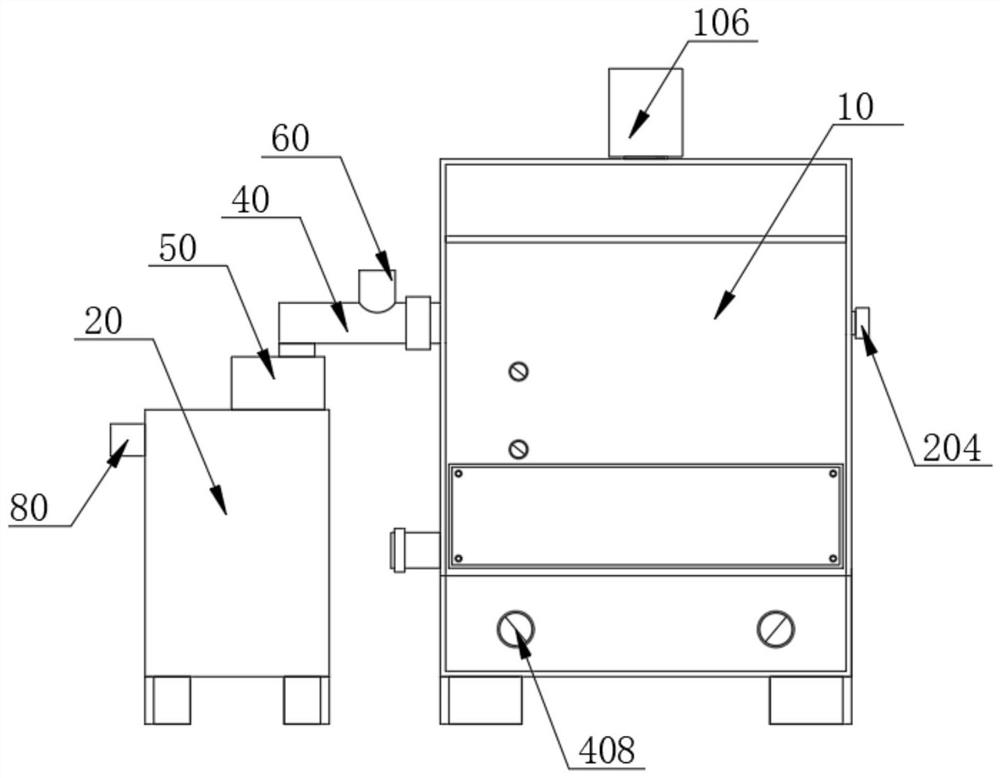

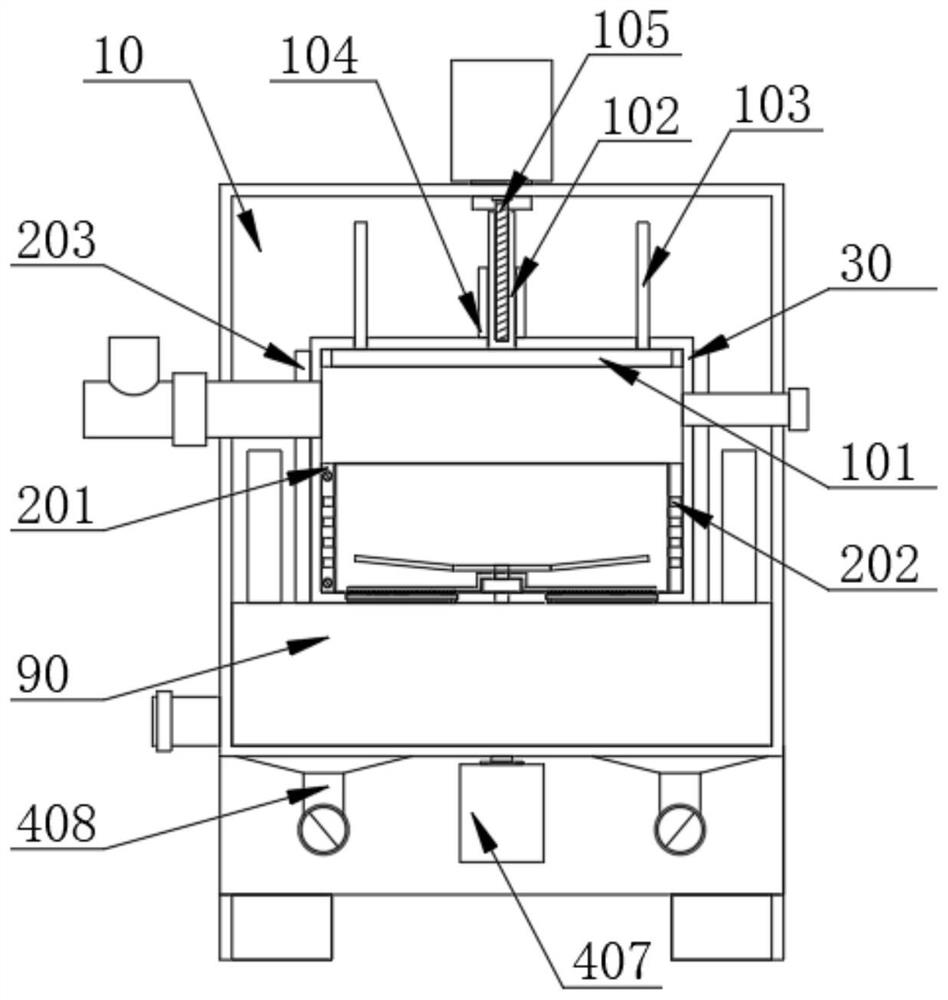

[0041] see Figure 1-7 Shown, a kind of preparation method of jackfruit fruit wine specifically comprises the following steps:

[0042] Step 1. Select the pulp of fresh jackfruit fruit and perform enzymatic hydrolysis treatment to obtain jackfruit enzymatic hydrolysis slurry, wherein the jackfruit enzymatic hydrolysis slurry is obtained by enzymatic hydrolysis at 45°C for 90 min and then boiling to kill the enzyme;

[0043] Step 2. Pass the obtained jackfruit enzymatic slurry into a fermentation device for fermentation treatment. First, pass the pineapple enzymatic slurry into the material box 20 for quantification, and then pump the jackfruit enzymatic slurry inside the material box 20 through the material pump 50 Into the feed pipe 40, the jackfruit enzymolysis slurry and yeast are dropped into the inside of the fermenter 30 by the feed pipe 40, and then the inside of the feed pipe 40 is sealed;

[0044] Step 3: Use the pressure sensor at the bottom of the piston plate 101 ...

Embodiment 2

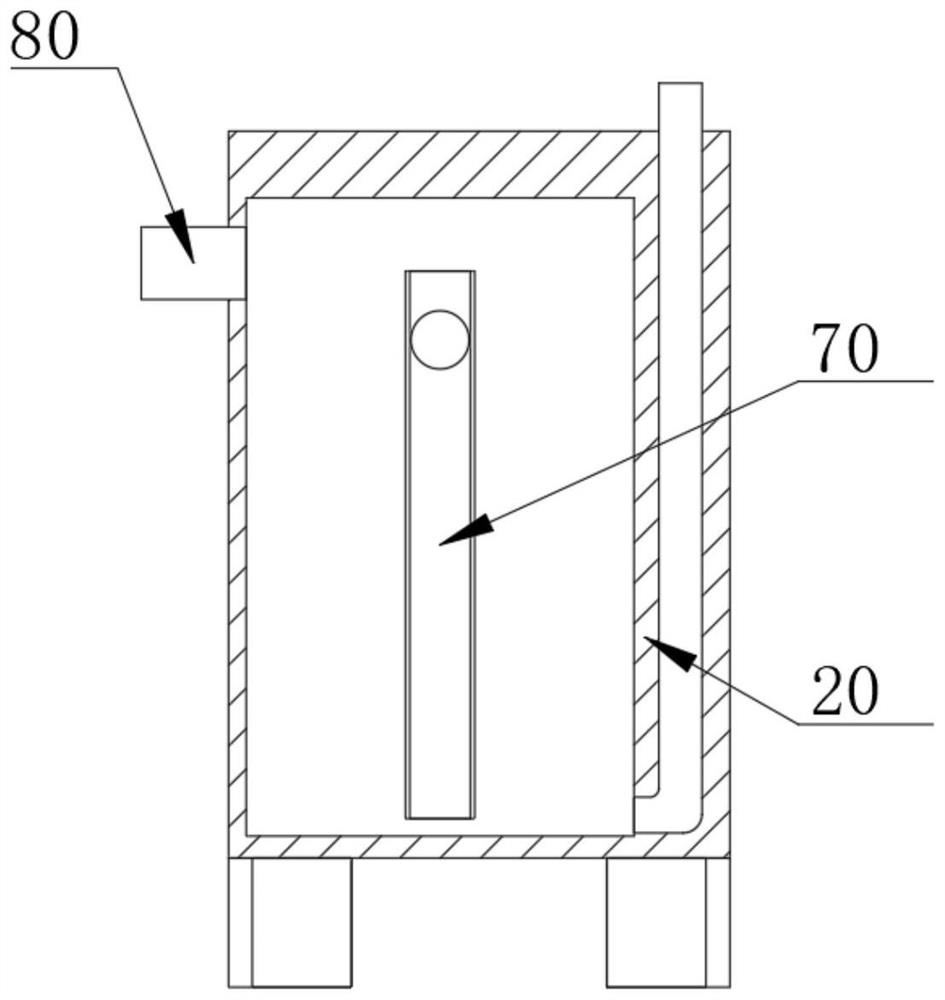

[0050] see Figure 1-7 As shown, the fermentation device in the present invention includes a fermentation tank 10 and a material tank 20, a fermentation tank 30 is arranged inside the fermentation tank 10, and a feed pipe 40 is provided on one side of the fermentation tank 30, and a material pump is provided on the top of the material tank 20 50, and the feed end of the material pump 50 is communicated with the bottom of the feed box 20, the discharge end of the feed pump 50 is communicated with one end of the feed pipe 40, and the top of the feed pipe 40 is connected with a feed pipe 60, the feed tank A liquid level sensor 70 is provided inside the tank 20, and a feed pipe 80 is communicated above the left side of the tank 20;

[0051] Pass the jackfruit enzymatic hydrolysis slurry into the inside of the feeder 20 through the feed pipe 80, wherein the jackfruit enzymatic hydrolysis slurry is obtained by enzymatically hydrolyzing the jackfruit pulp with pectinase, and use the ...

Embodiment 3

[0060] In the present invention, the discharge mechanism also includes a second discharge rack 401 located inside the clarification tank 90, and the inside of the second discharge rack 401 is fixedly connected to the surface of the rotating rod 301, and the two sides of the clarification tank 90 bottom are provided with second Discharge hole 402, and the inside of two second discharge holes 402 is all provided with second strainer 403, the bottom of second discharge frame 401 contacts with the upper surface of two second strainer 403, utilizes rotating rod 301 The second discharge frame 401 is driven to rotate, and the bottom of the second discharge frame 401 scrapes the upper surface of the second filter screen 403 to prevent the fermentation material from clogging the inside of the second filter screen 403 . The top of the clarification tank 90 is provided with a feed sleeve 404, and the top of the feed sleeve 404 communicates with the inside of the fermenter 30. The inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com