Pathogen zero-emission tail gas treatment device

A tail gas treatment and zero discharge technology, which is applied in the field of tail gas treatment devices for zero discharge of pathogens and tail gas treatment devices for zero discharge of highly pathogenic pathogens, can solve the problems of being unable to achieve zero discharge of highly pathogenic pathogens, and achieve the goal of ensuring real Reliability, the effect of uniform heating of airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Design and use of the exhaust gas treatment apparatus: Example embodiment of a

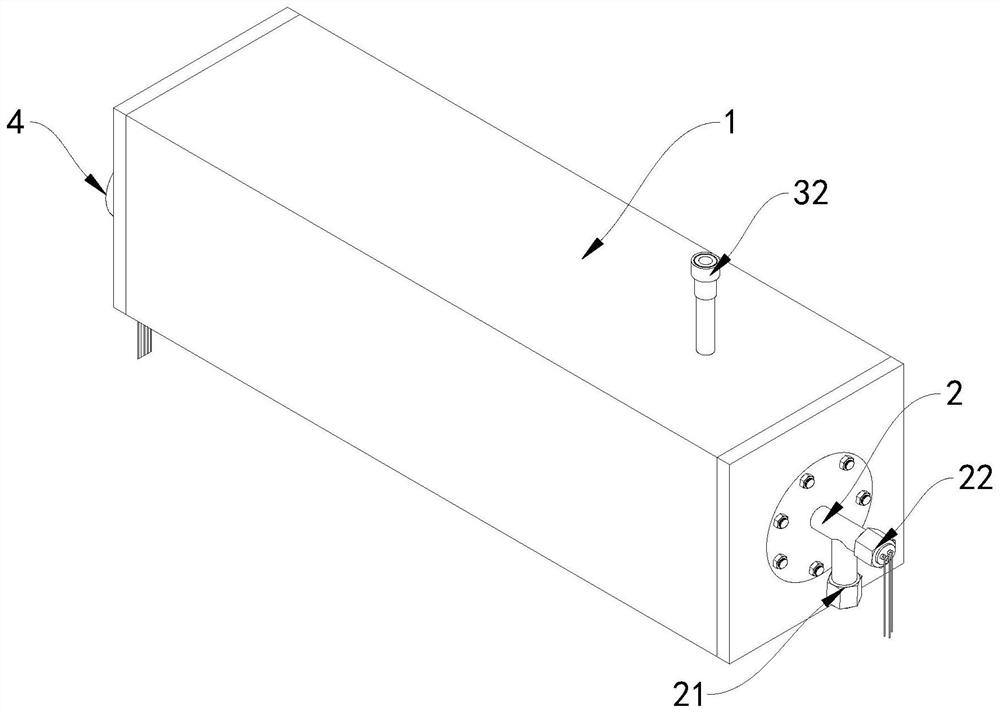

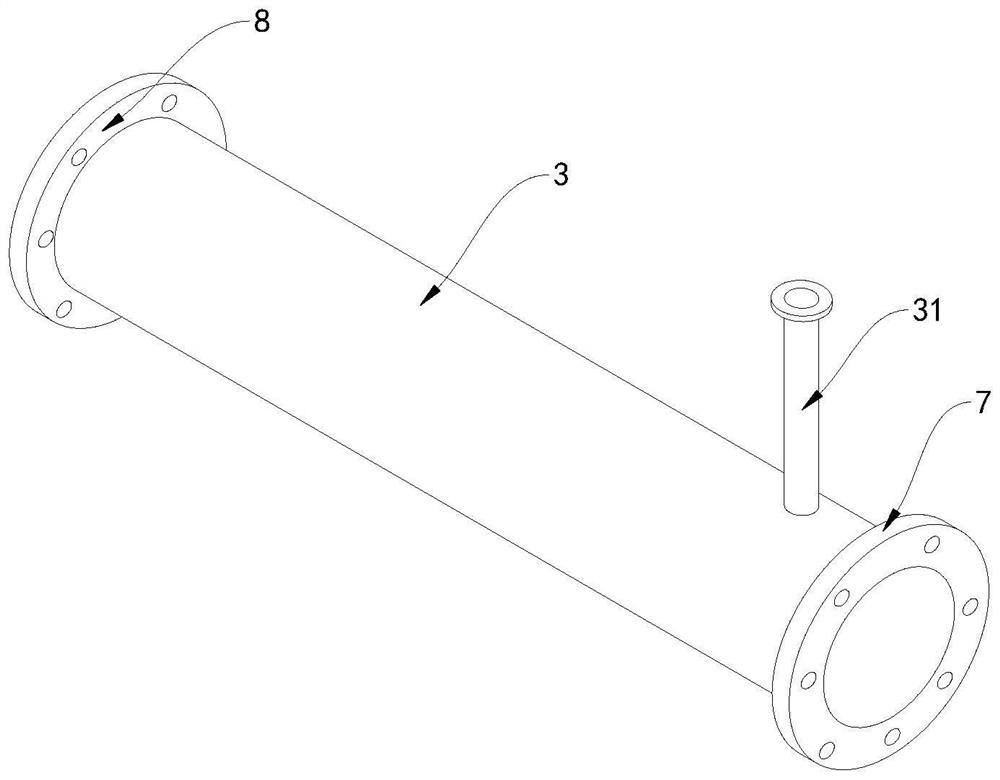

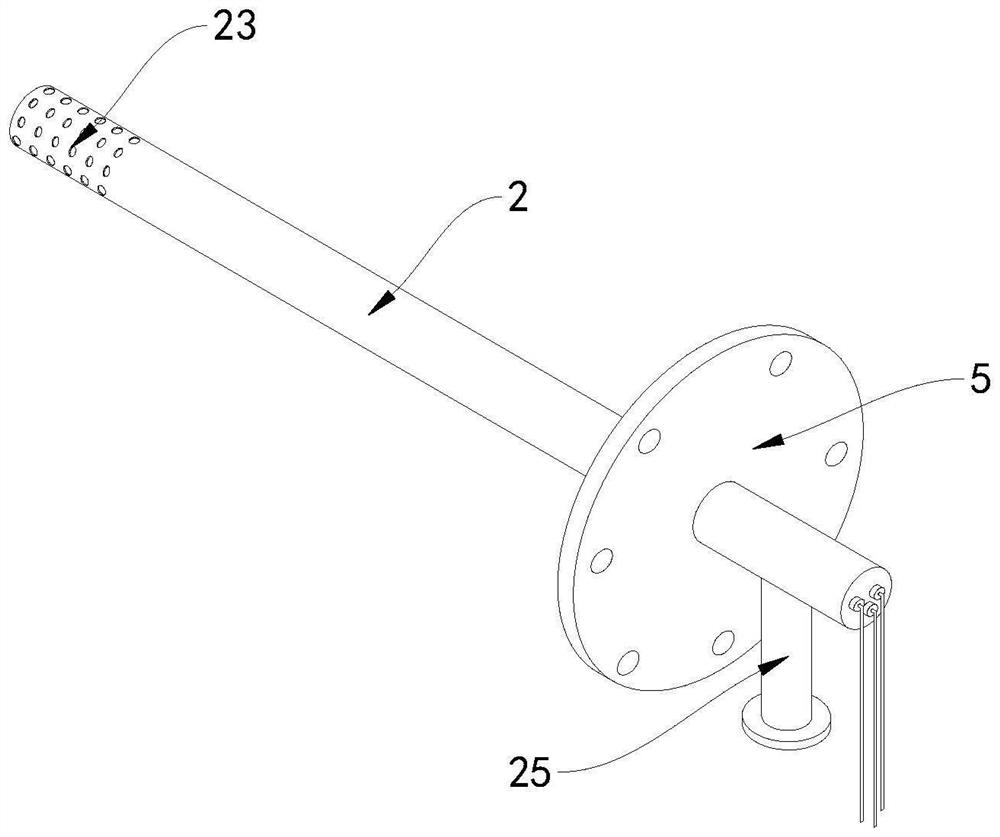

[0041] See figure 1 , Figure 8 , The exhaust gas treatment apparatus for pathogen zero emissions, the apparatus is a closed box structure, comprising an insulating housing, the inner cylinder body 2, an outer cylinder body 3 and a heating assembly 4. See figure 2 , Figure 7 , Figure 8 , An outer surface of the cylinder body 3 is provided with a intake pipe 31, both ends sealed welded flanges 7 and three four flanges 8, one end of the inner cylinder 2 through the main body and extending from the inner to the outer cylinder hole 7 of the flange three inner body 3 and the flange 7 three (three flange 5 and a flange adapter 7) sealing one end of the outer tubular body 3 connected through a flange 5, the other end of the inner cylinder main body 2 of the external cylinder body 3 external. See Image 6 , Figure 8 42, the four 8, the heating assembly 4 comprises a flange 6 and two electric heating elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com