CEMS (Continuous Emission Monitoring System) sampling system and method for horizontal flue of main discharge port of coal-fired unit

A horizontal flue and coal-fired unit technology, applied in the field of sampling systems, can solve problems such as the unsatisfactory distance between the front and rear flue elbows, the high cost of chimney reconstruction, and the short horizontal flue section, so as to avoid the decrease of pollutant concentration and eliminate Uneven concentration of pollutants and the effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

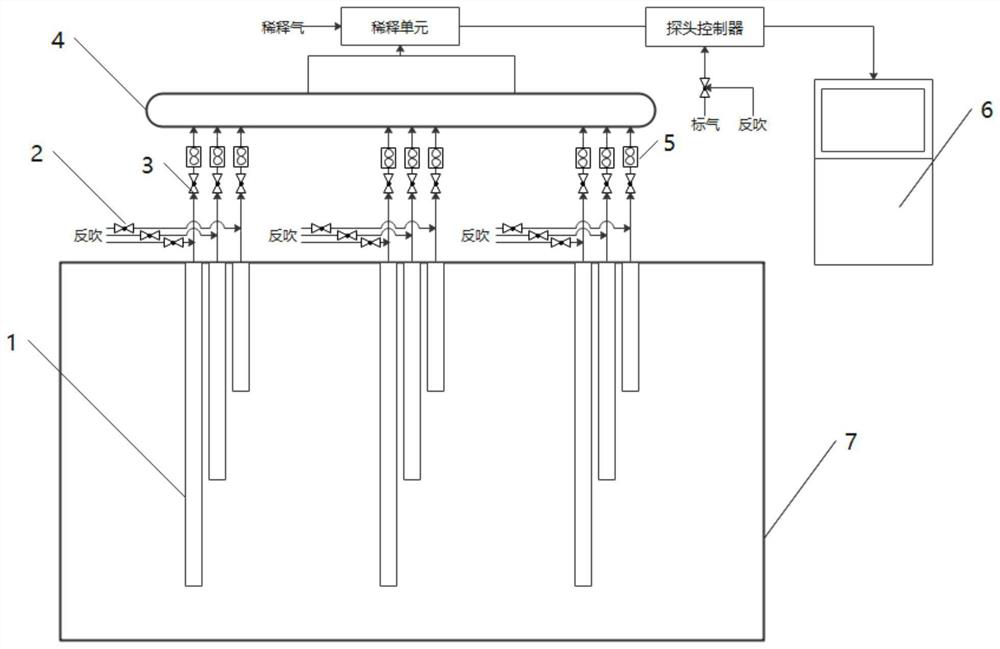

[0026] Embodiment 1 of the present application provides a CEMS sampling system for the horizontal flue of the main outlet of a coal-fired unit, including a sampling branch pipe 1, a backflushing solenoid valve 2, a sampling solenoid valve 3, a mixing main pipe 4, a flow regulating valve 5, a dilution unit and probe controller. On the measurement section of the flue 7 at the main exhaust outlet, several sampling branch pipes 1 form a group and are arranged almost at the same horizontal position, that is, the tops of the sampling branch pipes 1 are at the same height, and the lengths of the sampling branch pipes 1 in the same group are selected with equal differences. Several groups are arranged in the horizontal direction of the road 7. Each sampling branch pipe 1 is connected to the mixing main pipe 4 through the sampling solenoid valve 3 and the flow regulating valve 5 in turn, and the mixing main pipe 4 is connected to the gas analyzer 6 through the dilution unit and the pro...

Embodiment 2

[0035] Embodiment 2 of the present application provides a working method of the CEMS sampling system for the horizontal flue of the main outlet of the coal-fired unit, including the following steps:

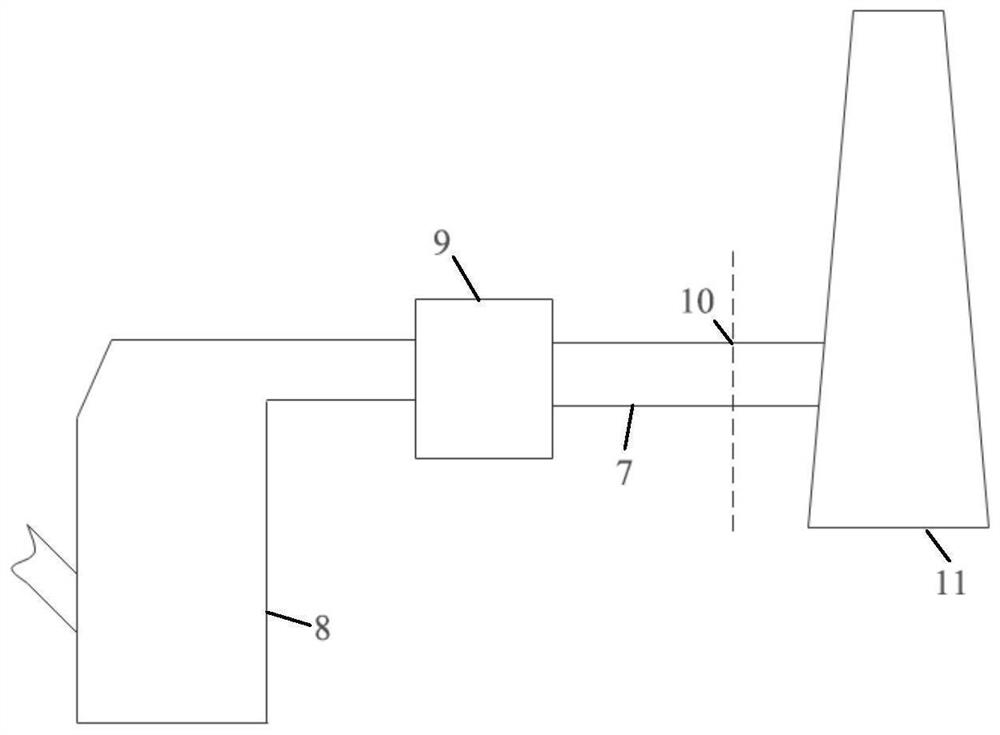

[0036] S1. The flue gas at the outlet of the desulfurization tower 8 (FGD) or the outlet of the wet electrostatic precipitator 9 (WESP) flows through the section where the flue gas sampling branch pipe 1 is located, and the flue gas enters the sampling branch pipe 1 of the clean flue gas through the sampling holes of each branch pipe, and then merges in The mixed main pipe 4 of the clean flue gas, and then enters the CEMS meter (that is, the gas analyzer 6) at the main discharge port to measure the concentration of pollutants in the flue gas online in real time;

[0037] S2. The sampling solenoid valve 3 and the blowback solenoid valve 2 are remote control valves. Normally, the sampling solenoid valve 3 is opened and the blowback solenoid valve 2 is closed. The sampling solenoid ...

Embodiment 3

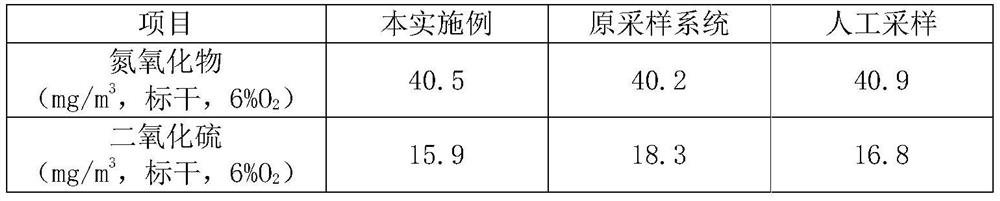

[0041]The chimneys of a coastal coal-fired power plant are shared by two units. The CEMS measurement points for the net flue gas of each unit are installed on the straight pipe section from the outlet of the desulfurization tower (FGD) to the chimney. The original sampling system is a single point, located in the flue In the middle of the top, there are problems such as complex smoke flow field and poor representativeness of measuring points. Now a new set of sampling system is added, the structure includes sampling branch pipe 1, blowback solenoid valve 2, sampling solenoid valve 3, mixing main pipe 4, flow regulating valve 5, dilution unit and probe controller, located at the outlet of desulfurization tower (FGD) to The top of the rectangular flue of the horizontal straight pipe section of the chimney, the cross-sectional size of the rectangular flue (excluding the insulation layer) is 5.2m (horizontal) × 11.6m (vertical). After the on-site multi-working condition test, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com