Short-process recovery method of waste lithium iron phosphate positive electrode material

A technology for lithium iron phosphate and positive electrode materials, which is applied in the field of short-process recycling of waste lithium iron phosphate positive electrode materials, can solve the problems of high cost and long recycling process of waste lithium iron phosphate materials, and achieve low cost, good industrialization potential, good The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

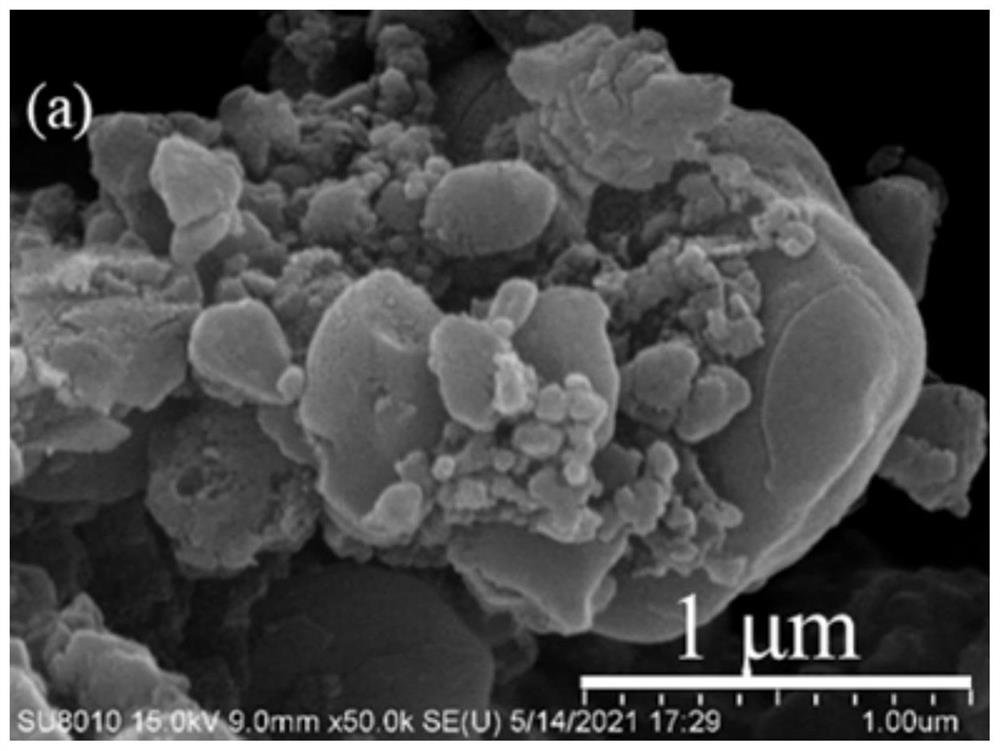

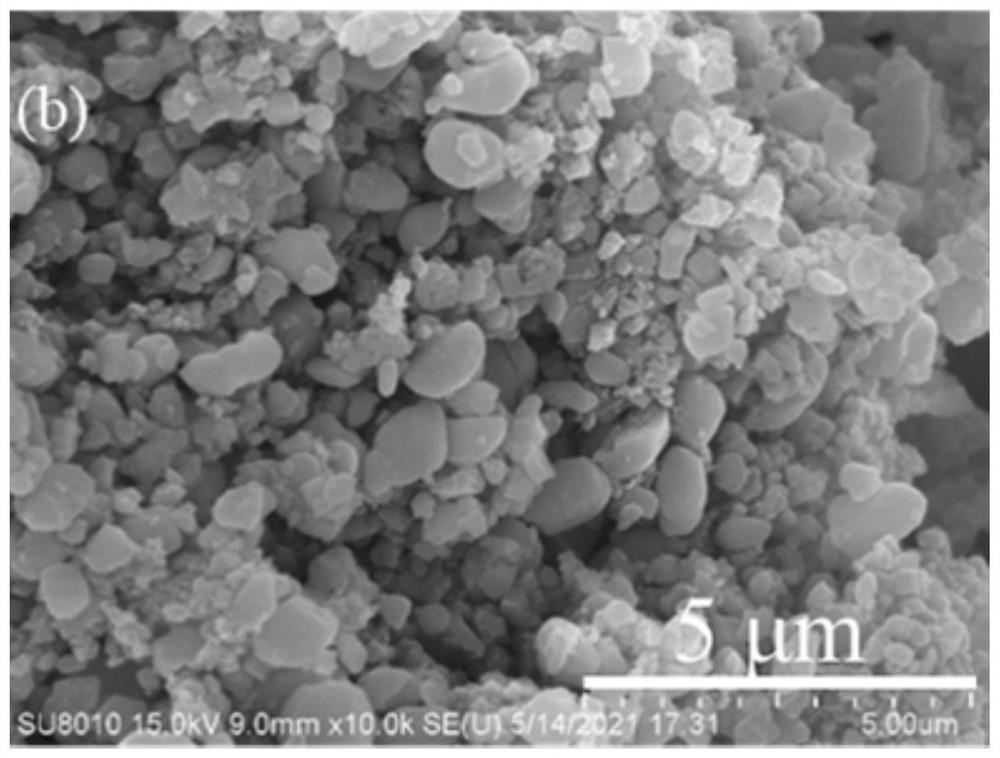

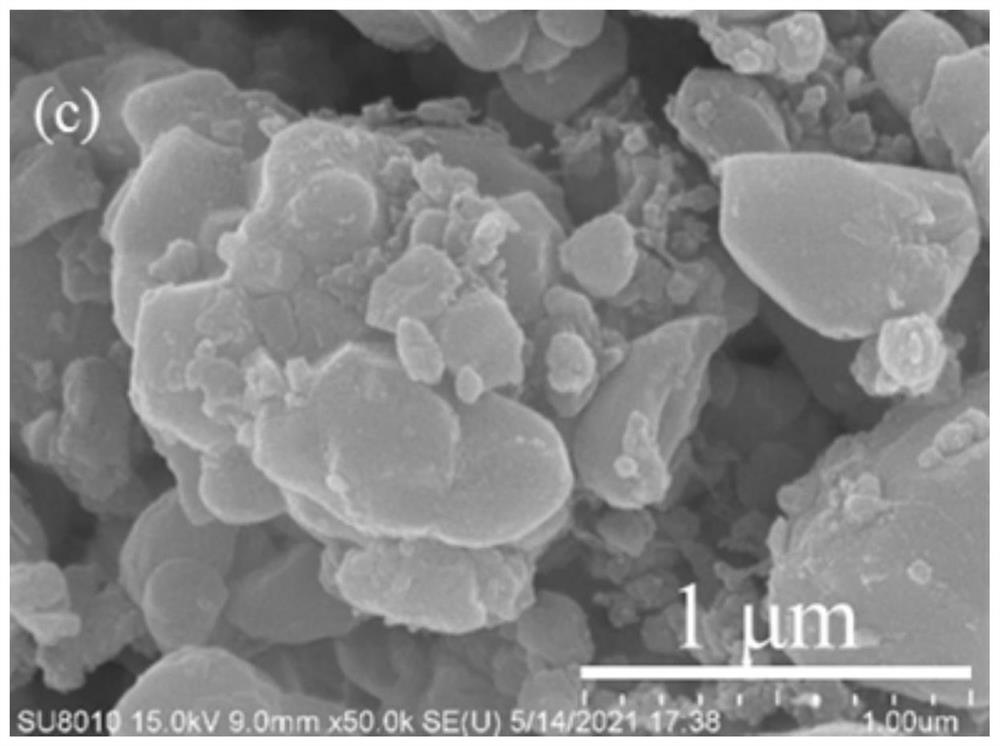

[0027] Specific implementation mode 1: In this implementation mode, a short-process recovery method of waste lithium iron phosphate positive electrode material is carried out according to the following steps:

[0028] 1. Soak the positive electrode sheet material of the waste lithium iron phosphate battery in deionized water at 25°C for 0.5-1min, and then soak in deionized water at 90°C for 0.5-1min; repeat the above steps twice to obtain a sheet Waste lithium iron phosphate material; after drying the waste lithium iron phosphate material in pieces, place them in a ball mill to grind for 1-3 hours to obtain waste lithium iron phosphate material powder, the ball-to-material ratio is (10-30):1;

[0029] 2. Put the waste lithium iron phosphate material powder in N-methyl-2 pyrrolidone, stir magnetically for 10-14 hours, filter after the stirring, and obtain a black precipitate. The quality of the waste lithium iron phosphate material powder is the same as that of N- The volume ra...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the positive electrode sheet material of the waste lithium iron phosphate battery described in step 1 is the waste lithium iron phosphate positive electrode sheet that has been cycled 500 times, 1000 times and 1500 times.

[0031] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying in step 1 is: drying the waste lithium iron phosphate material in pieces at a temperature of 60°C for 8 hours.

[0033] Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com