Linear production line and production process of power tabs

A linear, production line technology, applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of increased production cost, low production efficiency, poor stability, etc., to improve processing accuracy, prevent material belt deviation, improve Adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

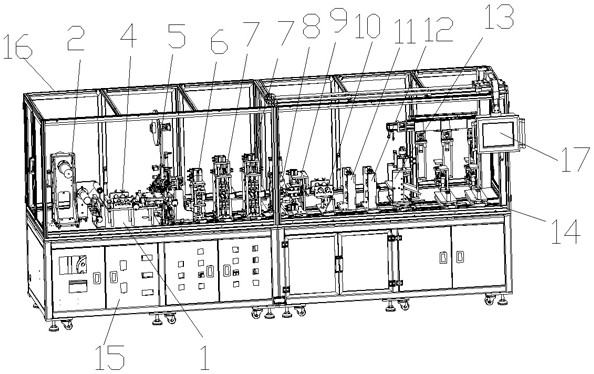

[0074] see Figure 1-20 , the present invention relates to a linear production line for power lugs. On the general mounting plate 1, there are sequentially arranged a feeding deviation correction device, a leveling guide preheating device 4, a glue pulling device 5, and a hot pressing device 6. , at least one internal heating device 7, high frequency device 8, cold pressing device 9, shaping device 10, pulling device 11, pressing device 12, cutting device 13 and chamfering device 14.

[0075] The total mounting plate 1 is fixed on the base frame 15, and an upper frame 16 is arranged around the total mounting plate 1, and the upper frame 16 protects each station on the total mounting plate 1, and the upper frame 16 is slidably connected with a touch screen display17.

[0076] The leveling guide preheating device 4, the glue pulling device 5, the hot pressing device 6, the internal heating device 7, the high frequency device 8, the cold pressing device 9, the shaping device 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com