Oil and gas field desulfurization wastewater advanced oxidation treatment device and treatment method thereof

A desulfurization wastewater, advanced oxidation technology, applied in mining wastewater treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of harsh reaction conditions, difficult treatment, large amount of sludge, etc. control, enhance biodegradability, and recover heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

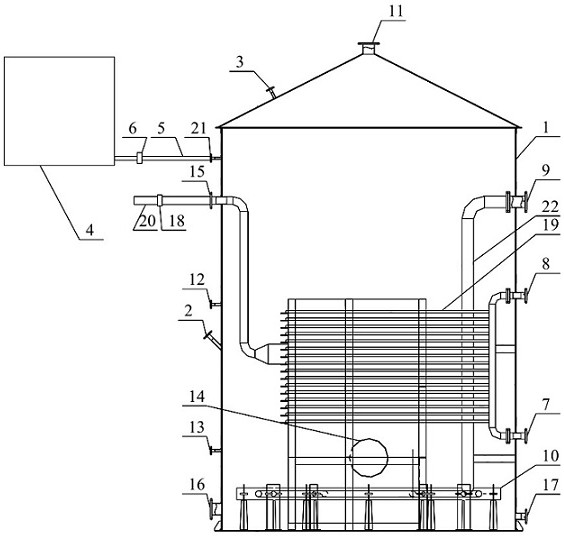

[0030] Such as figure 1 Shown:

[0031] An advanced oxidation treatment device for oil and gas field desulfurization wastewater provided by the present invention includes an advanced oxidation tank 1, a temperature sensor for monitoring the temperature of the wastewater in the advanced oxidation tank 1, a pressure sensor for monitoring the pressure in the advanced oxidation tank 1, and a control device; A heating device and an aeration device are arranged in the tank 1, and the advanced oxidation tank 1 is provided with a waste water inlet 15, a waste water outlet 16, and a dosing inlet 21; the advanced oxidation tank 1 is connected with a waste water inlet pipe and a waste water outlet The liquid pipe, the waste water inlet pipe and the waste water outlet pipe are respectively connected on the waste water inlet 15 and the waste water outlet 16 of the advanced oxidation tank 1; On the pressure gauge interface 3; the heating device, aeration device, temperature sensor, and pre...

Embodiment 2

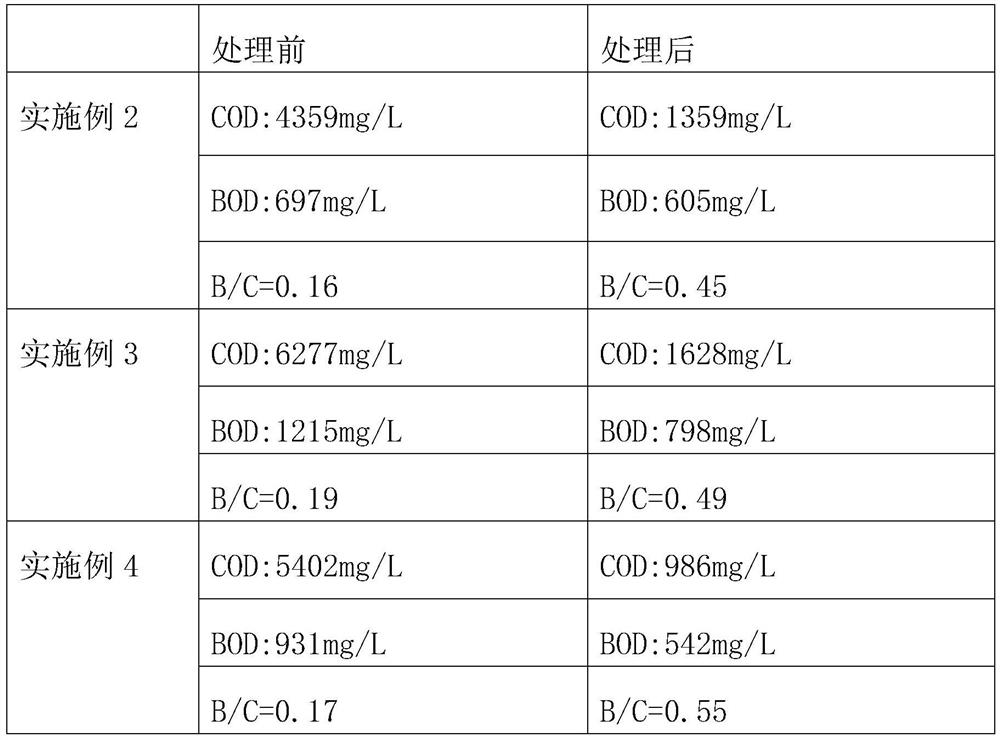

[0044] A method for advanced oxidation treatment of oil and gas field desulfurization wastewater provided by the present invention is treated by using the advanced oxidation treatment device for oil and gas field desulfurization wastewater in Example 1, specifically:

[0045] (1) Oil and gas field desulfurization wastewater enters the advanced oxidation tank 1 from the waste water inlet pipe 20 through the feed pump 18, and simultaneously adds persulfate advanced oxidant; Composed of fine lime powder; the dosage of sodium persulfate is 2.5‰ of the weight of desulfurization wastewater in oil and gas fields, the dosage of sodium hydroxide is 0.6‰ of the weight of desulfurization wastewater in oil and gas fields, and the dosage of lime fine powder is the weight of desulfurization wastewater in oil and gas fields 2‰.

[0046] (2) Raw steam at 120°C is introduced to raise the temperature, the temperature of the oil and gas field desulfurization wastewater in the advanced oxidation ...

Embodiment 3

[0049] A method for advanced oxidation treatment of oil and gas field desulfurization wastewater provided by the present invention is treated by using the advanced oxidation treatment device for oil and gas field desulfurization wastewater in Example 1, specifically:

[0050] (1) Oil and gas field desulfurization wastewater enters the advanced oxidation tank 1 from the wastewater inlet pipe 20 through the feed pump 18, and simultaneously adds persulfate advanced oxidant; in the present embodiment, the persulfate advanced oxidizer is made of potassium persulfate, sodium hydroxide Composed of fine lime powder; the dosage of potassium persulfate is 2.8‰ of the weight of desulfurization wastewater in oil and gas fields, the dosage of sodium hydroxide is 0.7‰ of the weight of desulfurization wastewater in oil and gas fields, and the dosage of lime fine powder is the weight of desulfurization wastewater in oil and gas fields 2.3‰.

[0051] (2) Raw steam at 120°C is introduced to rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com