Separation method for indium leachate of waste liquid crystal display

A separation method and leachate technology, which is applied in the field of separation of indium leachate from waste liquid crystal screens, can solve the problems of high cost, unfriendly environment, low efficiency of indium recovery, etc., achieve low industrialization cost, solve the problem of recycling, and have a clear process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

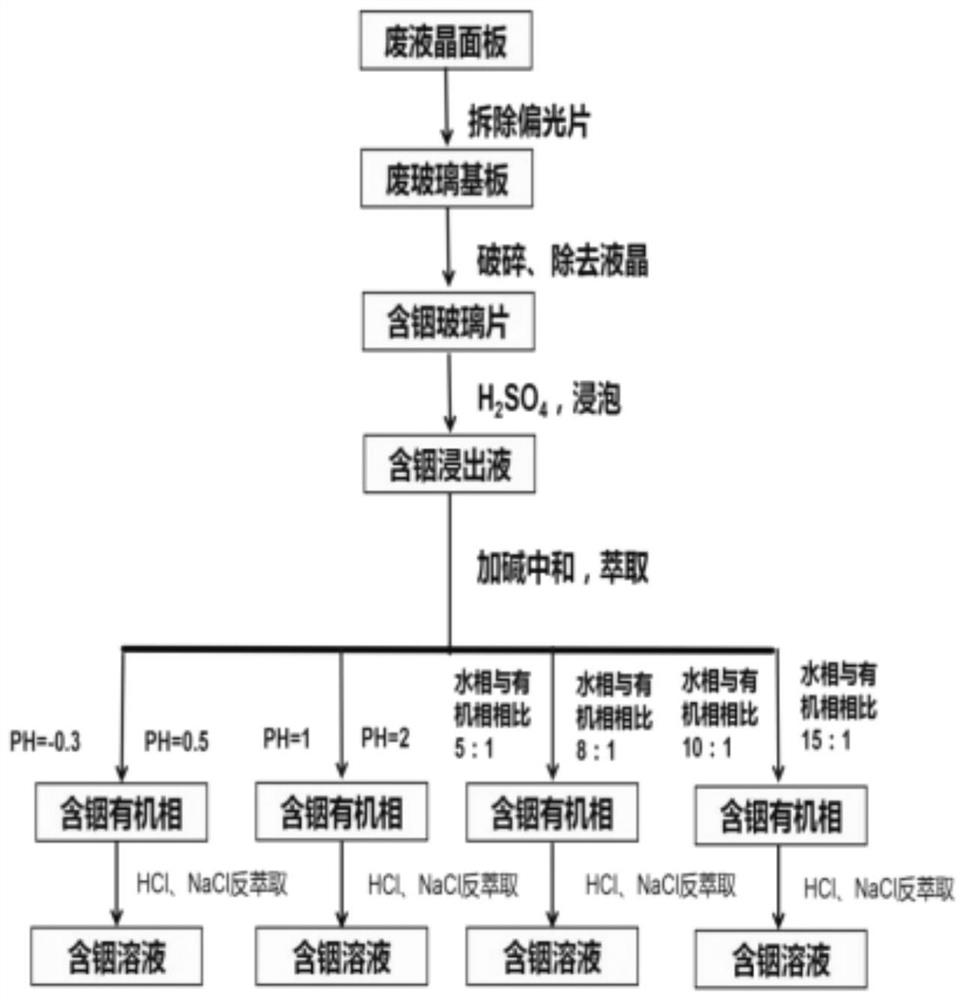

[0031] Such as figure 1 As shown, a method for separating the indium leachate of waste liquid crystal screens shown in this embodiment comprises the following steps:

[0032] (1) The waste liquid crystal panel is broken to obtain a 5cm strip, and the strip is rolled to break the glass stuck on the polarizer;

[0033] (2) Carry out acid leaching treatment to the product processed through above-mentioned steps (1), the used leaching solution of acid leaching is that concentration is 20%H 2 SO 4 solution, the acid leaching process temperature is 50°C, and the soaking time is 4 hours;

[0034] (3) Slowly add caustic soda to the leachate obtained in step (2) for neutralization, adjust the pH to -0.3, brown rubber is separated out, filter the separated impurities, and reclaim the filter residue tin hydroxide as a chemical raw material;

[0035] (4) filter the gained filtrate of step (3) gained acid dipping liquid and extract, get the leachate of 500ml and add in the separatory fu...

Embodiment 2

[0038] A method for separating the indium leaching solution of waste liquid crystal screens shown in this embodiment comprises the following steps:

[0039] (1) The waste liquid crystal panel is broken to obtain a 5cm strip, and the strip is rolled to break the glass stuck on the polarizer;

[0040] (2) Carry out acid leaching treatment to the product processed through above-mentioned steps (1), the used leaching solution of acid leaching is that concentration is 20%H 2 SO 4 solution, the acid leaching process temperature is 50°C, and the soaking time is 4 hours;

[0041] (3) Slowly add caustic soda to the leachate obtained in step (2) for neutralization, adjust the pH to 0.5, brown rubber is separated out, filter the precipitated impurities, and reclaim the filter residue tin hydroxide as a chemical raw material;

[0042] (4) filter the gained filtrate of step (3) gained leachate and extract, get the leachate of 500ml and add in the separatory funnel, then add 100ml organic...

Embodiment 3

[0045] A method for separating the indium leaching solution of waste liquid crystal screens shown in this embodiment comprises the following steps:

[0046] (1) The waste liquid crystal panel is broken to obtain a 5cm strip, and the strip is rolled to break the glass stuck on the polarizer;

[0047] (2) Carry out acid leaching treatment to the product processed through above-mentioned steps (1), the used leaching solution of acid leaching is that concentration is 20%H 2 SO 4 solution, the acid leaching process temperature is 50°C, and the soaking time is 4 hours;

[0048] (3) Slowly add caustic soda to the leachate obtained in step (2) for neutralization, adjust the pH to 1, brown rubber is separated out, filter the precipitated impurities, and reclaim the filter residue tin hydroxide as a chemical raw material;

[0049] (4) filter the gained filtrate of step (3) gained leachate and extract, get the leachate of 500ml and add in the separatory funnel, then add 100ml organic pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com