In-situ functional coated positive electrode material, preparation method thereof and all-solid-state lithium battery

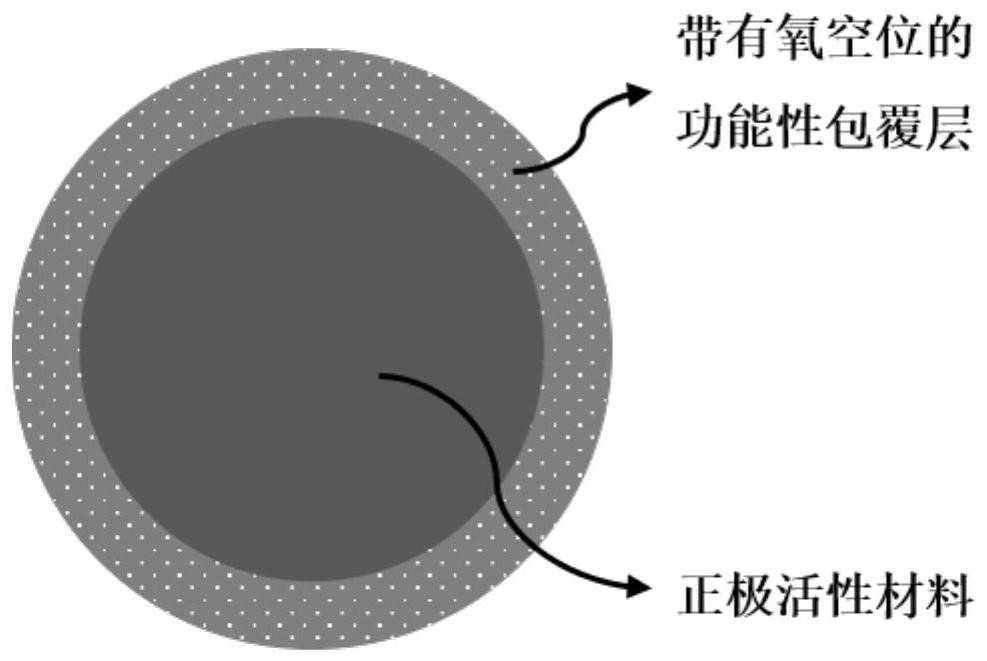

A positive electrode material and positive active material technology, applied in the field of all-solid-state lithium batteries, can solve problems such as poor interface compatibility, poor electrochemical reaction at the interface, poor contact, etc., and achieve low impedance, good practical industrial application prospects, and controllable thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

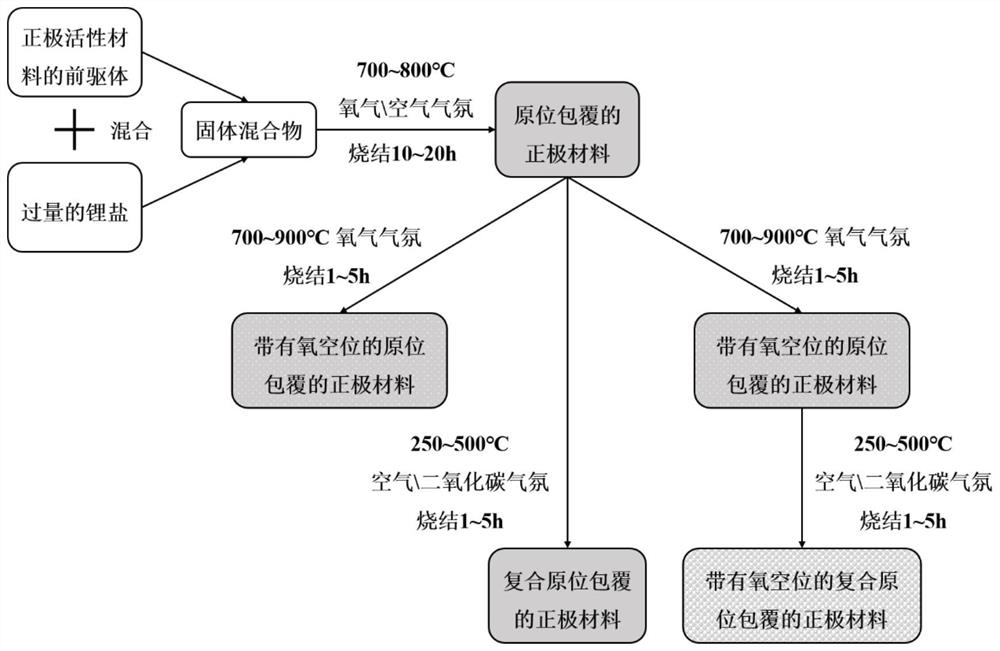

[0045] This embodiment provides an in-situ functionally coated positive electrode material and a preparation method thereof, wherein the positive electrode active material is polycrystalline NCM811 with a particle size of 10 μm, and the composition of the in-situ functional coating layer is Li 2 CO 3 , with a thickness of 8nm. Concrete preparation comprises the following steps:

[0046] The precursor of the positive electrode active material NCM811 was mixed with an excess of 15% Li 2 CO 3 Lithium salts were evenly mixed, and sintered at 700°C for 10 hours in an air atmosphere, Li 2 CO 3 Part of the lithium salt participated in the synthesis of the positive electrode active material NCM811, and part of the in-situ generation of thin and uniform Li on its surface 2 CO 3 The coating layer forms a positive electrode material with an in-situ generated functional coating layer on the surface.

Embodiment 2

[0048] This embodiment provides an in-situ functionally coated positive electrode material and a preparation method thereof, wherein the positive electrode active material is polycrystalline NCM811 with a particle size of 10 μm, and the composition of the in-situ functional coating layer is Li 2 O, with a thickness of 8 nm. Concrete preparation comprises the following steps:

[0049] The precursor of the positive electrode active material NCM811 was mixed with an excess of 15% LiOH·H 2 O lithium salts were evenly mixed, and sintered at 750°C in an oxygen atmosphere for 15 hours, LiOH·H 2 Part of the O lithium salt participated in the synthesis of the positive electrode active material NCM811, and part of the in-situ generation of thin and uniform Li on its surface 2 O coating layer, forming a positive electrode material with an in-situ-generated functional coating layer on the surface.

Embodiment 3

[0051] This embodiment provides an in-situ functionally coated positive electrode material and a preparation method thereof, wherein the positive electrode active material is polycrystalline NCM811 with a particle size of 10 μm, and the composition of the in-situ functional coating layer is Li 2 O-oxygen vacancies with a thickness of 8 nm. Concrete preparation comprises the following steps:

[0052] (1) The precursor of the positive electrode active material NCM811 was mixed with an excess of 15% LiOH·H 2 O lithium salts were evenly mixed, and sintered at 720°C in an oxygen atmosphere for 12h, LiOH·H 2 Part of the O lithium salt participated in the synthesis of the positive electrode active material NCM811, and part of the in-situ generation of thin and uniform Li on its surface 2 O coating layer, forming a positive electrode material with an in-situ-generated functional coating layer on the surface.

[0053] (2) The product obtained in step (1) was further sintered at 900 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com