Yarn feeding and guiding device for textile machine

A textile machine and wire technology, which is applied in the field of wire feed wire devices for textile machines, can solve the problems of not taking into account the contact friction between the yarn and the fixture, affecting the quality of textiles, and restrictions on appearance, applicability and practicability, and achieving practicality. Good, fast guidance, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

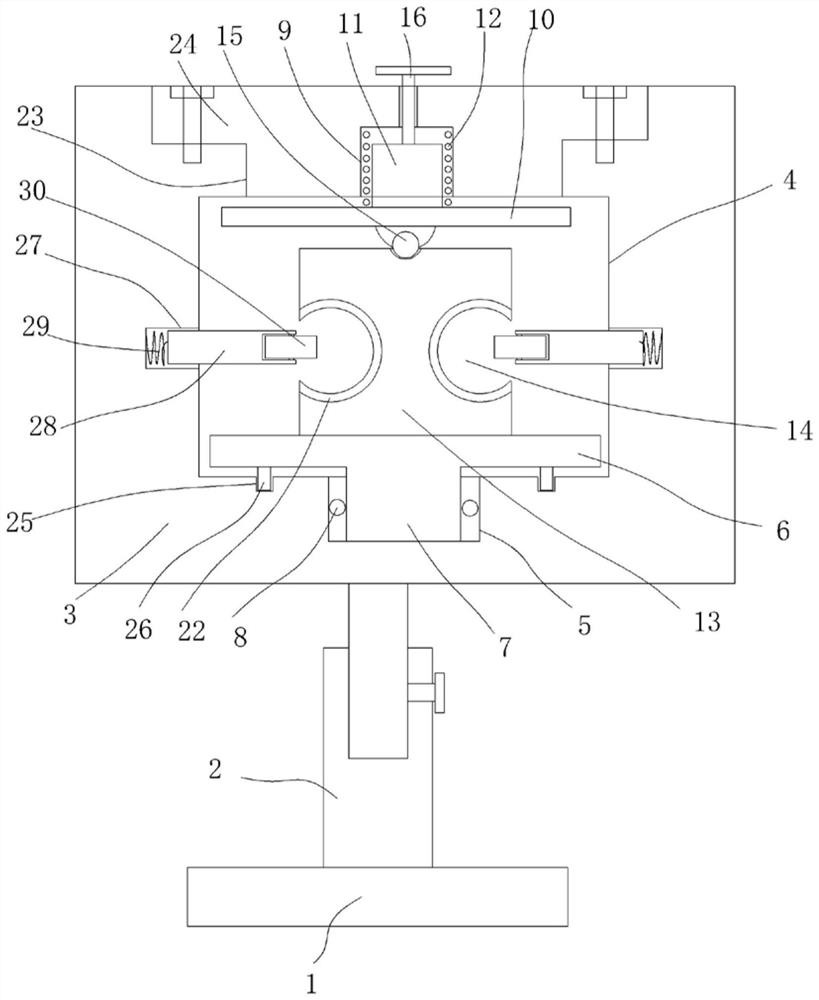

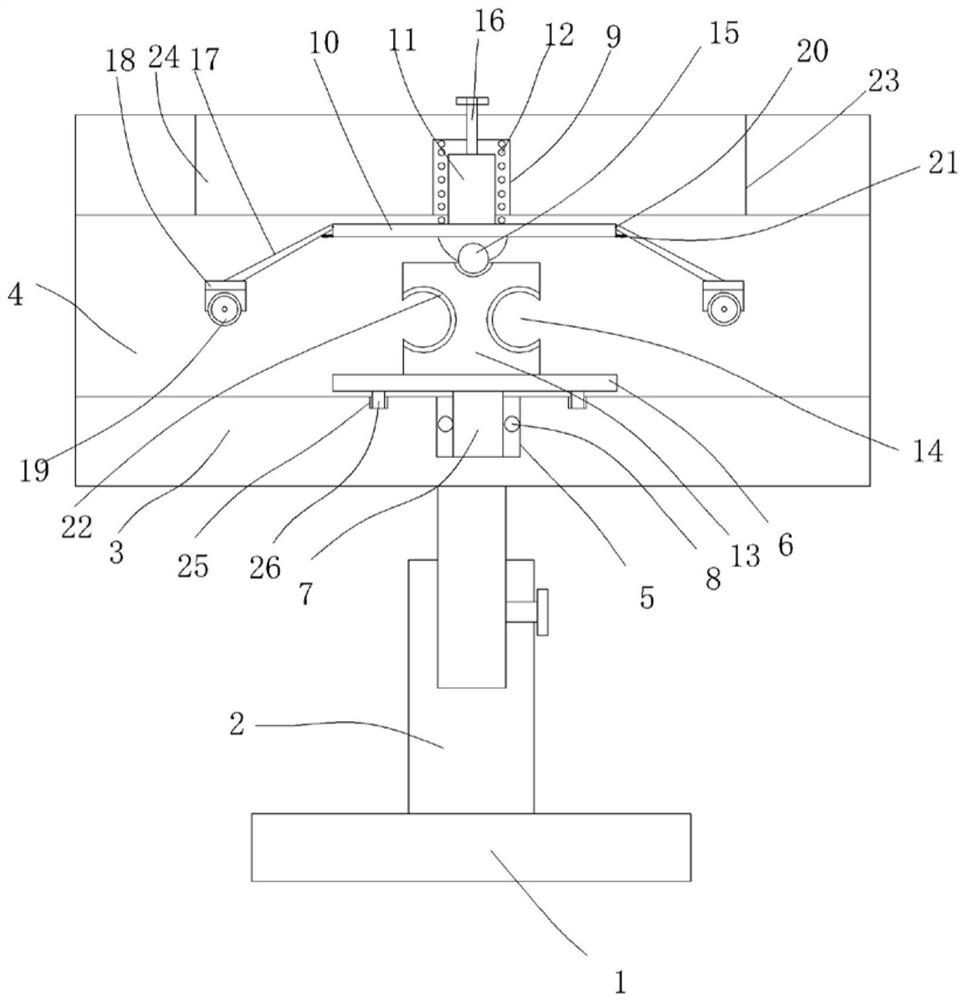

[0016] figure 1 with figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a sectional structure diagram of the present invention.

[0017] See figure 1 with figure 2 , an incoming wire device for a textile machine, comprising a mounting base 1. In this embodiment, the mounting base is a metal structure, and the telescopic support rod 2 is arranged on the mounting base, and the bottom end of the telescopic rod is fixed on the On the mounting seat, in order to ensure the stability and reliability of use, the weight of the mounting seat is relatively heavy, so as to ensure the overall center of gravity, and the device housing 3 fixed on the top of the telescopic pole. In this embodiment, the device housing is The plastic shell has a circular structure. In actual use, a wire loading operation groove 23 is opened on the side of the device housing, and a shell cover 24 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com