Water-resistant ink-absorbing coating material as well as preparation method and application thereof

An ink-absorbing coating and raw material technology, applied in the field of water-resistant ink-absorbing coating materials and their preparation, can solve the problems of poor water resistance, complicated process, high cost, etc., and achieve improved fixing effect, good compatibility, and durability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

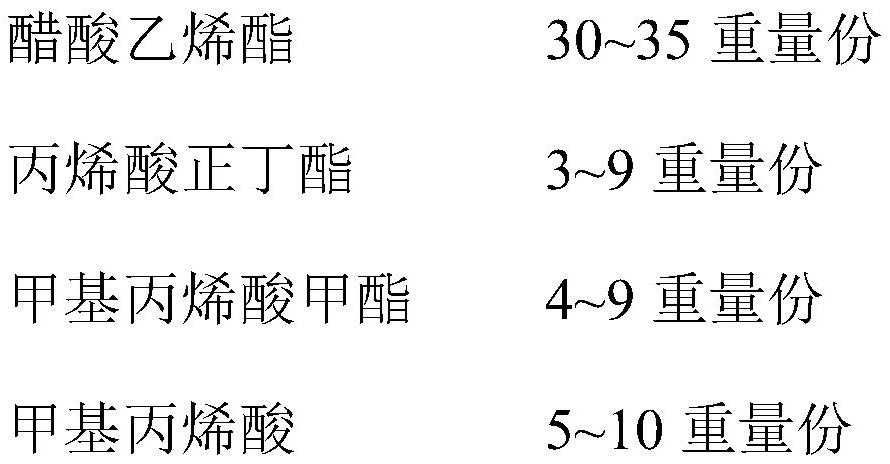

[0073] A water-resistant and ink-absorbing coating material comprises the following components in parts by weight:

[0074]

[0075] The preparation method of the water-resistant and ink-absorbing coating material provided in this embodiment comprises the following steps:

[0076] (1) Put 12.5 parts by weight of vinyl acetate and 25 parts by weight of ethanol in the reaction kettle, raise the temperature to 70°C, and count when there is a reflux phenomenon in the kettle, and continue to heat up to 80°C and keep it for 20 minutes, and put 22.5 parts by weight of vinyl acetate ester, 6 parts by weight of n-butyl acrylate, 5 parts by weight of methyl methacrylate, 8 parts by weight of methacrylic acid, 0.7 parts by weight of azobisisobutyronitrile and 11 parts by weight of ethanol are added dropwise to the reactor, and the time for adding After the dropwise addition, the initial reaction was 2 hours, and then 0.3 parts by weight of azobisisobutyronitrile and 7 parts by weight ...

Embodiment 2

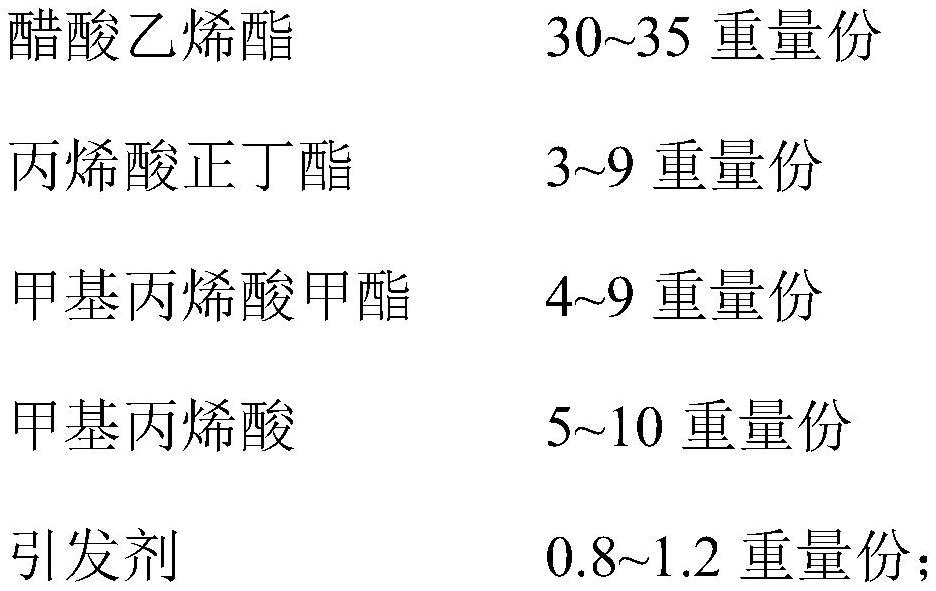

[0080] A water-resistant and ink-absorbing coating material comprises the following components in parts by weight:

[0081]

[0082] The preparation method of the water-resistant and ink-absorbing coating material provided in this embodiment comprises the following steps:

[0083] (1) Put 10 parts by weight of vinyl acetate and 20 parts by weight of ethanol in the reaction kettle, raise the temperature to 70°C, and count when there is a reflux phenomenon in the kettle, and continue to heat up to 80°C and keep it for 20 minutes, and put 25 parts by weight of vinyl acetate ester, 3 parts by weight of n-butyl acrylate, 4 parts by weight of methyl methacrylate, 5 parts by weight of methacrylic acid, 0.6 parts by weight of azobisisobutyronitrile and 10 parts by weight of ethanol are added dropwise to the reactor, and the time for adding After 4 hours of initial reaction after the addition, add 0.2 parts by weight of azobisisobutyronitrile and 5 parts by weight of ethanol dropwis...

Embodiment 3

[0087] A water-resistant and ink-absorbing coating material comprises the following components in parts by weight:

[0088]

[0089] The preparation method of the water-resistant and ink-absorbing coating material provided in this embodiment comprises the following steps:

[0090] (1) Put 15 parts by weight of vinyl acetate and 20 parts by weight of ethanol in the reaction kettle, raise the temperature to 70°C, and count when there is a reflux phenomenon in the kettle, and continue to heat up to 80°C and keep it for 20 minutes, and put 20 parts by weight of vinyl acetate ester, 9 parts by weight of n-butyl acrylate, 9 parts by weight of methyl methacrylate, 10 parts by weight of methacrylic acid, 0.8 parts by weight of azobisisobutyronitrile and 12 parts by weight of ethanol are added dropwise to the reactor, and the time for adding After the dropwise addition, the initial reaction was 2 hours, and then 0.4 parts by weight of azobisisobutyronitrile and 8 parts by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com