High-strength high-thermal-conductivity die-casting aluminum alloy material and preparation method thereof

A high thermal conductivity, cast aluminum alloy technology, applied in the field of aluminum alloy materials and their preparation, can solve the problems of lack of high yield strength, high heat dissipation performance, high yield strength, etc., to achieve improved thermal conductivity, increased corrosion resistance, improved The effect of alloy strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention also discloses a method for preparing a high-strength and high-thermal-conductivity die-casting aluminum alloy material, which is characterized in that it includes the following steps:

[0030] (1) Carry out component ratio and smelting according to the above-mentioned alloy material to form a melt, and the melting temperature is 730-760° C.;

[0031] (2) After the melt is transferred to the static furnace, it is refined with nitrogen and refining agent. The refining temperature is 720-750°C, and the time is 5-10 minutes. -700°C;

[0032] (3) Vacuum die-casting process is adopted, the temperature of molten aluminum is 650-670°C; the tensile strength at room temperature of the alloy as cast is ≥310Mpa, the yield strength is ≥180MPa, and the elongation is ≥7.5%; the tensile strength at a high temperature of 200 degrees is ≥260Mpa, and the yield strength ≥140Mpa, elongation ≥11.5%, alloy thermal conductivity at room temperature is 200-220w / (m·k);

[0033] (...

Embodiment

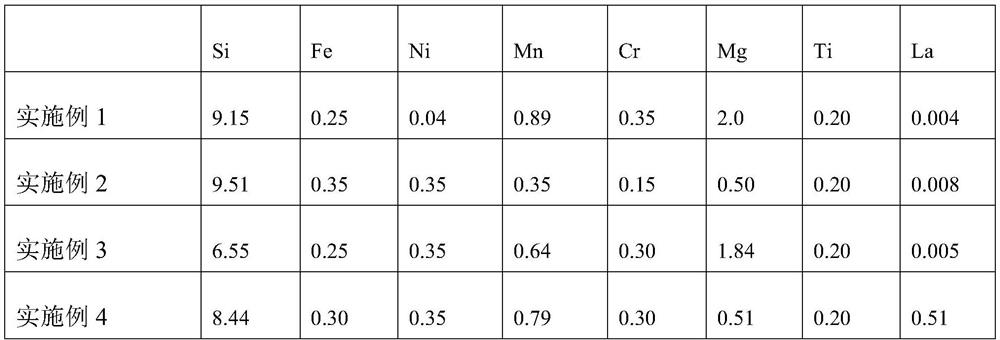

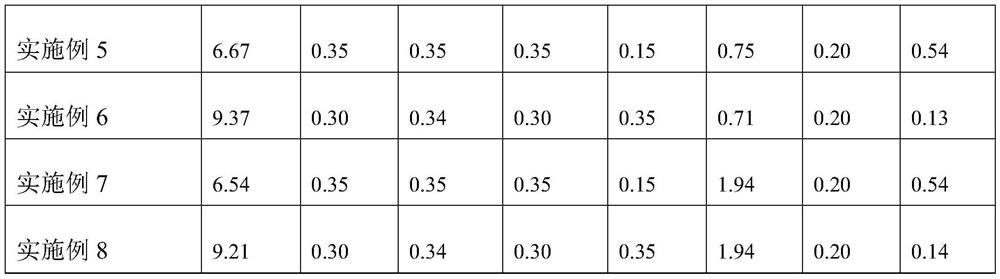

[0040] Composition table (mass fraction%)

[0041]

[0042]

[0043] Note: Example 1: No addition of Ni and rare earth La; Example 2: No addition of rare earth La, low Mg content; Example 3: No addition of rare earth La; Example 4: Low Mg content of only 0.51%; Example 5-8 are embodiments in the technical solution of the present invention.

[0044] According to the composition of the table, the alloy is melted, and then refined with nitrogen and refining agent. The refining temperature is 720-750°C, and the time is 5-10 minutes. Afterwards, the aluminum liquid is introduced into the side holding furnace of the die-casting machine at a temperature of 680-700 ° C, and the aluminum liquid is controlled within the range of 660-680 ° C for performance and thermal conductivity tests of vacuum die-casting radiators and test rods.

[0045] The die-casted test rods and radiators are subjected to T1 heat treatment. The aging heat treatment process is that the product is heated to...

Embodiment 5

[0050] Comparing Example 5 with Example 1, in the as-cast state, the tensile strength of the alloy is increased by 6.8%, the yield strength is increased by 19%, and the elongation is increased by 36%. After aging treatment, the tensile strength of the alloy is increased by 10%, and the yield strength is increased by 21%. %, elongation increased by 38%. The main reason is that the alloy in Example 1 does not undergo modification without the rare earth La, and the control of the rare earth La between 0.1-0.6% can significantly improve the strength and plasticity of the alloy, refine the grains and dendrites, and strengthen the dispersion of the second phase. And it can be strengthened by aging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com