Iron-molybdenum doped nickel sulfide/foamed nickel electrode and preparation method and application thereof

A technology of nickel foam and nickel sulfide, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of cumbersome steps and difficulty in increasing the amount of iron doping, and achieve the goal of increasing the amount of doping, low raw material cost, and reducing the risk factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

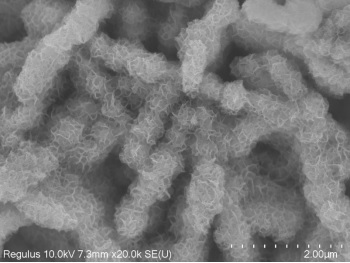

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing an iron-molybdenum-doped nickel sulfide nickel foam electrode, and the specific steps are as follows:

[0036] Step 1: Preparation of foamed nickel: Cut the foamed nickel into a rectangle with a size of 1 cm × 4.5 cm, and place the foamed nickel in 3M HCl, absolute ethanol and deionized water for ultrasonic cleaning for 10 minutes each time; Dry in a 60°C drying oven for 3 hours, and set aside after drying.

[0037] The second step: 2 mmol FeCl 3 ·6H 2 O, 1 mmol (NH 4 ) 6 Mo 7 o 24 4H 2 O and 2.2 mmol Na 2 S was dissolved in 50 ml of deionized water and stirred at room temperature to obtain a mixed solution;

[0038] The third step: Insert the 2 pieces of nickel foam obtained in the first step into the polytetrafluoro mold base, and the nickel foam remains in a vertical state; the polytetrafluoro base and the hydrothermal solution inserted into the nickel foam are added to the hydrothermal kettle, Fasten the hydroth...

Embodiment 2

[0041] This embodiment provides a method for preparing an iron-molybdenum-doped nickel sulfide / nickel foam electrode, and the specific steps are as follows:

[0042] The first step is to prepare foamed nickel: cut the foamed nickel into a rectangle with a size of 1 cm × 4.5 cm, and place the foamed nickel in 3M HCl, absolute ethanol and deionized water for ultrasonic cleaning for 10 minutes each time; Dry in a 60°C drying oven for 3 hours, and set aside after drying.

[0043] The second step: 1.5 mmol FeCl 3 ·6H 2 O, 1.5 mmol (NH 4 ) 6 Mo 7 o 24 4H 2 O and 2.2 mmol Na 2 S was dissolved in 50 milliliters of deionized water, and a hydrothermal solution was obtained after stirring;

[0044] The third step is to insert 2 pieces of foamed nickel obtained in the first step into the polytetrafluoro mold base, and the foamed nickel remains in a vertical state; the polytetrafluoro base and the hydrothermal solution inserted into the foamed nickel are added to the hydrothermal k...

Embodiment 3

[0046] This embodiment provides a method for preparing an iron-doped nickel sulfide / foamed nickel electrode without molybdenum doping. The specific steps are as follows:

[0047] The first step is to prepare foamed nickel: cut the foamed nickel into a rectangle with a size of 1 cm × 4.5 cm, and place the foamed nickel in 3M HCl, absolute ethanol and deionized water for ultrasonic cleaning for 10 minutes each time; Dry in a 60°C drying oven for 3 hours, and set aside after drying.

[0048] The second step: 3 mmol FeCl 3 ·6H 2 O and 2.2 mmol Na 2 S was dissolved in 50 milliliters of deionized water, and a hydrothermal solution was obtained after stirring;

[0049] The third step: Insert the 2 pieces of nickel foam obtained in the first step into the polytetrafluoro mold base, and the nickel foam remains in a vertical state; the polytetrafluoro base and the hydrothermal solution inserted into the nickel foam are added to the hydrothermal kettle, Fasten the hydrothermal kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com