Flexible film platinum resistance sensor and preparation method thereof

A flexible film, platinum resistance technology, applied in instruments, scientific instruments, electrical devices, etc., can solve the problems of insufficient sealing of the thin film resistance sensor structure, long thermal response time of surface temperature, error in temperature test results, etc. The effect of constant value accuracy, low insulation and radiation resistance, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

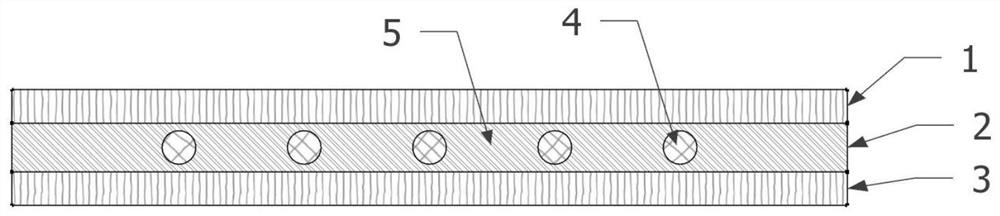

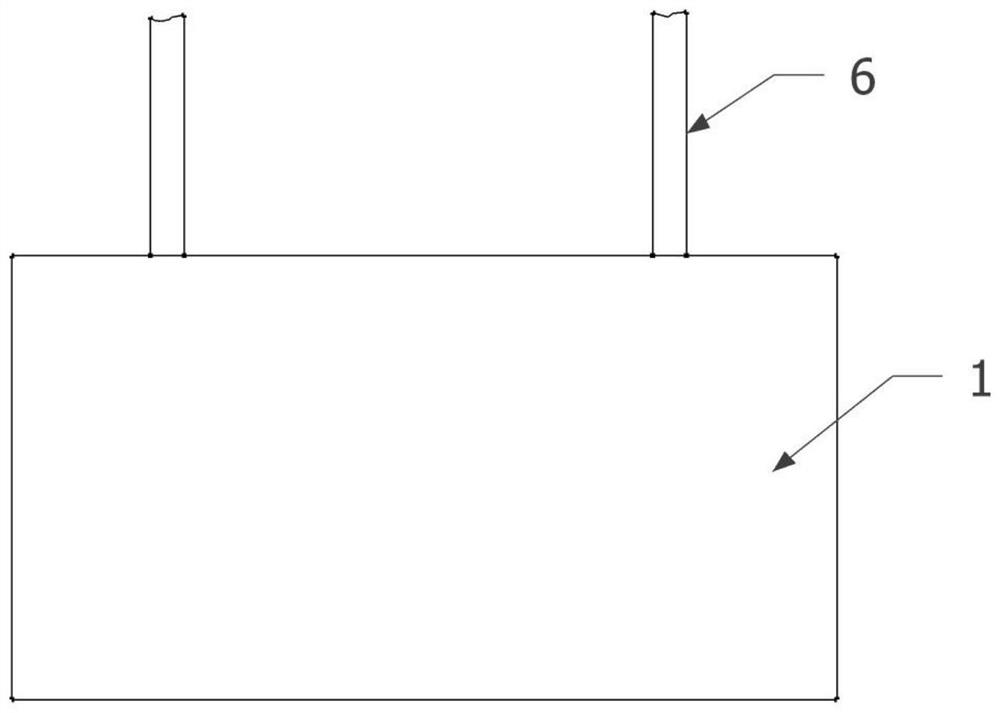

[0024] Such as figure 1 and figure 2 As shown, this embodiment provides a flexible thin-film platinum resistance sensor, including a flexible platinum resistance sensor substrate. The material of the imide base material layer 3, the polyimide cover layer 1 and the polyimide base material layer 3 is a polyimide film with a thickness of 0.05mm. The platinum resistance wire intermediate layer 2 includes platinum resistance wire 4 and sealant 5, the two ends of the platinum resistance wire 4 are connected to the wire 6, and the connection part between the platinum resistance wire and the wire is located in the platinum resistance wire intermediate layer 2, which protects the connection part The thickness of the middle layer of the platinum resistance wire is 0.06mm, the sealant 5 is polyimide, and the sealant 5 encapsulates the platinum resistance wire 4 to prevent water vapor and impurities from entering, and improve the reliability and long-term stability of the flexible thin-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com