High-voltage motor coil anti-corona structure repairing method based on nonlinear material

A technology of non-linear materials and anti-corona structures, applied in the shape/style/structure of winding insulation, winding insulation materials, manufacturing motor generators, etc., can solve problems such as long repair period, high repair cost, and poor repair quality. Achieve the effects of saving repair costs, avoiding demolition, and shortening the repair period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention is a field repair method for stator coil insulation of a high-voltage motor, which includes the following process steps:

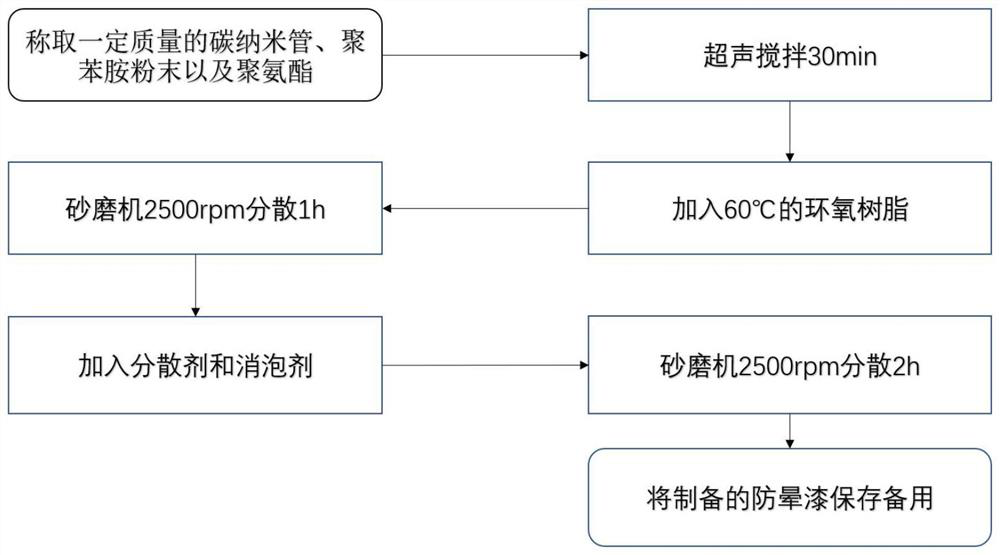

[0030] a. Preparation of anti-halation paint: the process is as follows figure 1 shown. Mix carbon nanotubes, polyaniline powder and polyurethane according to the above ratio and ultrasonically stir for 30 minutes. After mixing evenly, add epoxy resin heated to 60°C into the mixed solution according to the above ratio, place it in a sand mill, and add an appropriate amount of grinding The beads were dispersed at 2500rpm for 3 hours at high speed, and the dispersant and defoamer were added in the above ratio after dispersing for 2 hours, and the preparation of the anti-halation paint was completed at this time;

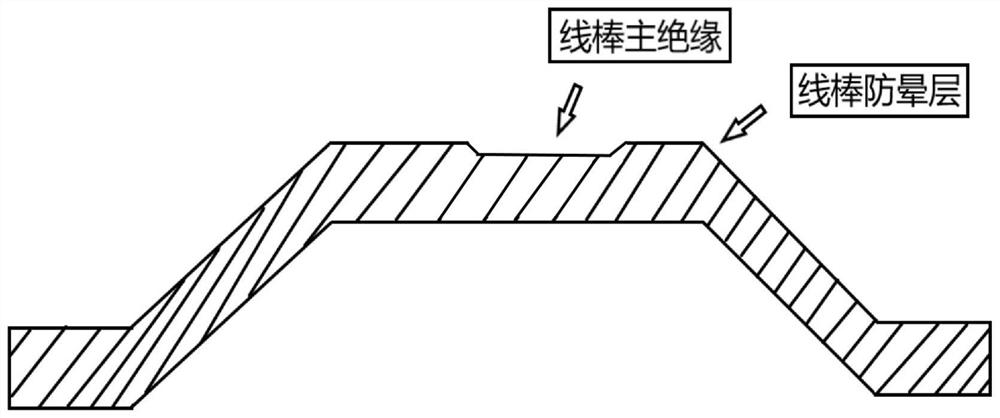

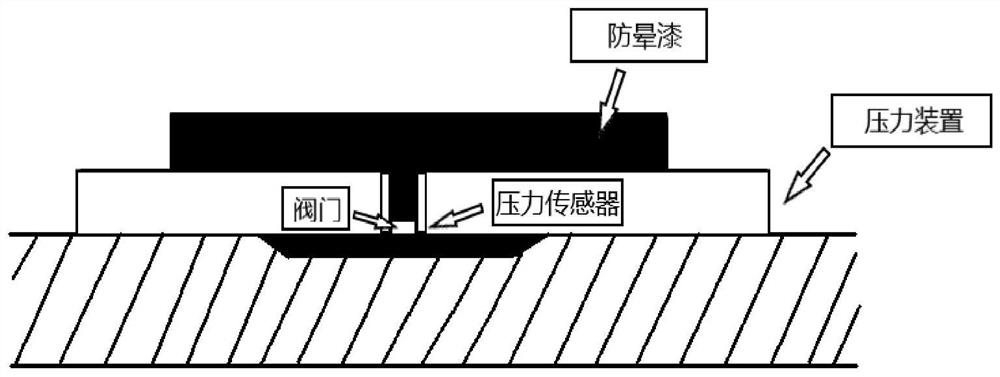

[0031] b. Clean the damaged part of the anti-halo structure of the coil: the damaged part of the anti-halo structure of the coil is as follows: figure 2 shown. Use a vacuum cleaner to clean the damaged part of the ring ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com