Green, energy-saving, low-carbon and environment-friendly T-series non-combustible insulation board and preparation method thereof

A low-carbon, environmentally friendly, thermal insulation board technology, which is applied in the field of building components, achieves excellent overall performance, improved energy saving and thermal insulation effects, and waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

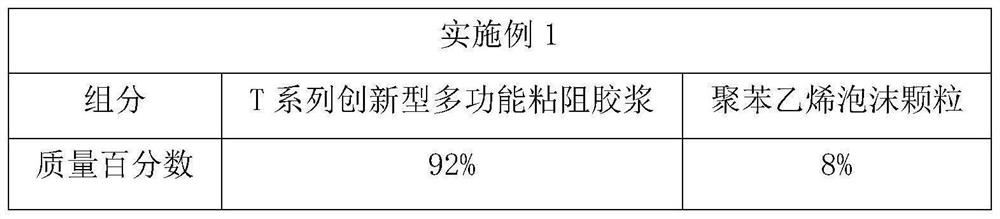

Embodiment 1

[0043] The invention provides a green, energy-saving, low-carbon and environment-friendly T series non-combustible thermal insulation board. The non-combustible thermal insulation board includes the following components in mass percentages, 92% of T series innovative multi-functional sticky-resistance glue and polystyrene foam particles 8 %;

[0044] The T-series innovative multi-functional viscous resistance mucilage includes the following components in parts by weight, 30 parts of inorganic viscous resistance coupling agent, 20 parts of tailings sand, 20 parts of urban construction waste, and 30 parts of T series new water-based special glue, 100 parts in total.

[0045] The inorganic viscous resistance coupling agent includes the following components in weight percentage,

[0046]

[0047]

[0048] The silicate is a mixture of calcium silicate and magnesium silicate.

[0049] The industrial silica fume is waste silica fume from flue gas tail gas produced from silicon...

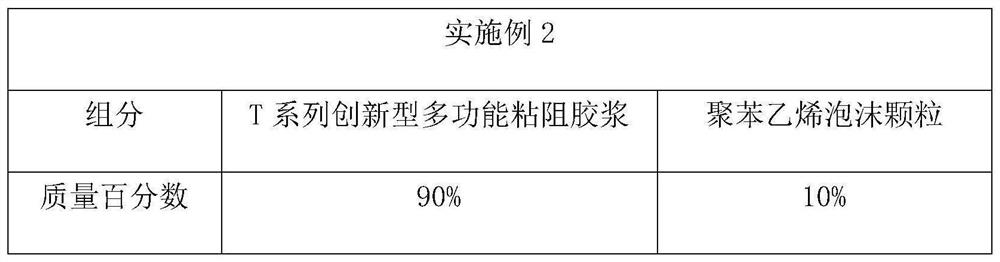

Embodiment 2

[0058] The invention provides a green, energy-saving, low-carbon and environment-friendly T series non-combustible thermal insulation board. The non-combustible thermal insulation board includes the following components in mass percentages, 90% of the T series innovative multi-functional viscous resistance glue and 10% of polystyrene foam particles %;

[0059] The T-series innovative multifunctional viscous resistance glue includes the following components in parts by weight, 24 parts of inorganic viscous resistance coupling agent, 24 parts of tailings sand, 16 parts of urban construction waste, and 36 parts of T series new water-based special glue, 100 parts in total.

[0060] The inorganic viscous resistance coupling agent includes the following components in weight percentage,

[0061]

[0062] The silicate is a mixture of iron silicate and aluminum silicate.

[0063] The industrial silica fume is waste silica fume from flue gas tail gas produced from silicon manganese,...

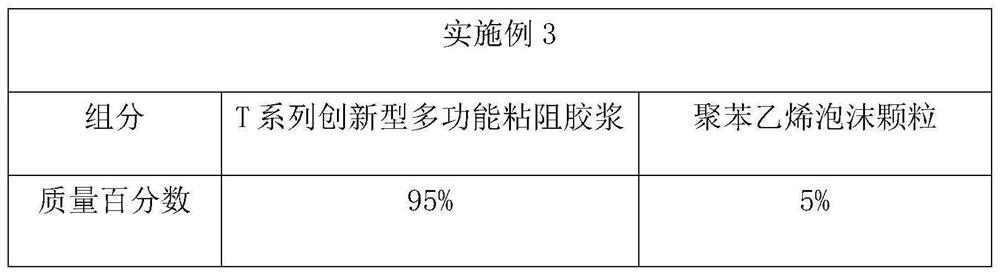

Embodiment 3

[0072] The invention provides a green, energy-saving, low-carbon and environment-friendly T series non-combustible thermal insulation board. The non-combustible thermal insulation board includes the following components in mass percentages, 95% of T series innovative multi-functional viscous resistance glue and polystyrene foam particles 5% %;

[0073] The T-series innovative multifunctional viscous resistance glue includes the following components in parts by weight, 36 parts of inorganic viscous resistance coupling agent, 16 parts of tailing sand, 24 parts of urban construction waste, and 24 parts of T series new water-based special glue, 100 parts in total.

[0074] The inorganic viscous resistance coupling agent includes the following components in weight percentage,

[0075]

[0076] The silicate is a mixture of aluminum silicate, sodium silicate and potassium silicate.

[0077] The industrial silica fume is waste silica fume from flue gas tail gas produced from silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com