Tread rubber with low content of anti-aging agent and preparation method thereof

An anti-aging agent and tread rubber technology, used in special tires, tire parts, transportation and packaging, etc. problems, to achieve the effect of improving passability and safety, and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

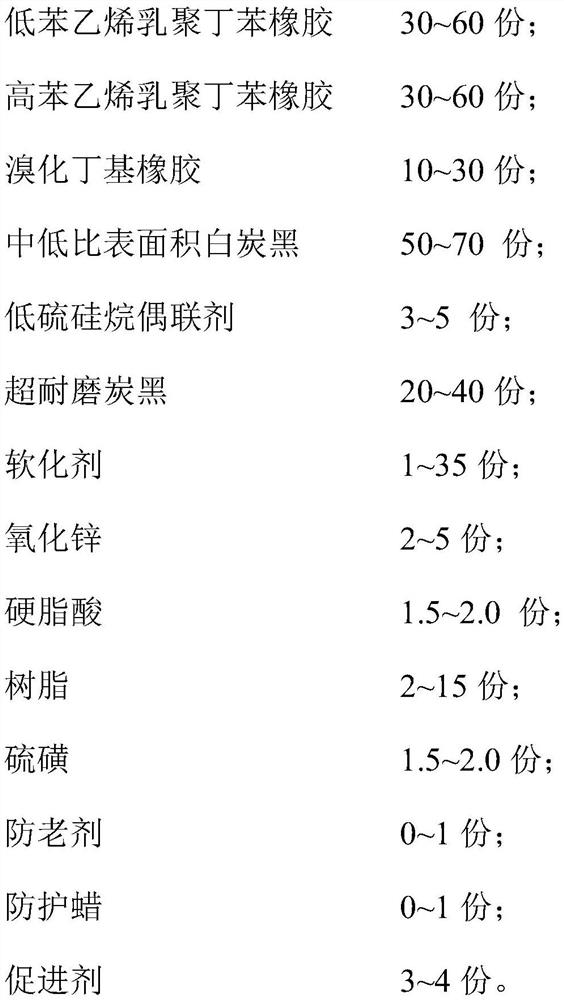

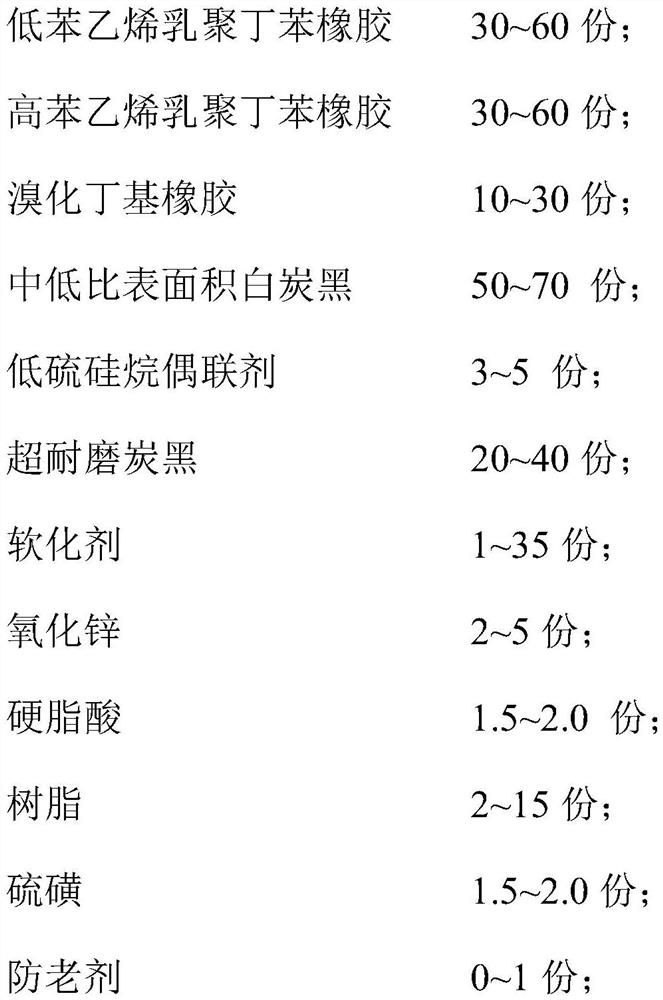

Method used

Image

Examples

Embodiment 1

[0034] Low styrene emulsion polystyrene butadiene rubber SBR1502: 30 parts, high styrene emulsion polystyrene butadiene rubber SBR1739: 55 parts, brominated butyl 3745: 15 parts, medium and low specific surface area white carbon black HD1115MP: 50 parts, low sulfur silane Coupling agent NXT363: 3 parts, super wear-resistant carbon black N234: 30 parts, 8 parts of environmentally friendly aromatic oil, 3 parts of zinc oxide, 1.5 parts of stearic acid, 5 parts of phenolic resin, sulfur 99 (1% oil-extended): 1.5 1.8 parts of accelerator CBS, 0.15 parts of accelerator TS, and 1.45 parts of accelerator D.

[0035] Put all the rubber into the F370 internal mixer, use the speed of 55RPM to mix for 20 seconds, lift the top bolt, and put all the weighed additives except sulfur and accelerator into the internal mixer through the feeding door and packing delivery pipe, respectively. When the temperature rises to 120°C (considering the temperature rise of the equipment, it is set to start...

Embodiment 2

[0038] Low styrene emulsion polystyrene butadiene rubber SBR1502: 40 parts, high styrene emulsion polystyrene butadiene rubber SBR1739: 40 parts, brominated butyl 3745: 20 parts, medium and low specific surface area white carbon black HD1115MP 50 parts, low sulfur silane Joint agent NXT363: 4.4 parts, super wear-resistant carbon black N234: 20 parts, environmentally friendly aromatic oil 10 parts, zinc oxide 3 parts, stearic acid 1.5 parts, phenolic resin ST1101: 5 parts, sulfur 99 (1% oil-extended): 1.6 parts, p-phenylenediamine antioxidant 0.5 parts, protective wax 0.5 parts, accelerator CBS: 1.8 parts, accelerator TS: 0.15 parts, accelerator D: 1.45 parts.

[0039] Put all the rubber into the F370 internal mixer, use the speed of 55RPM to mix for 20 seconds, lift the top bolt, and put all the weighed additives except sulfur and accelerator into the internal mixer through the feeding door and packing delivery pipe, respectively. When the temperature rises to 120°C (consideri...

Embodiment 3

[0042] Low styrene emulsion polystyrene butadiene rubber SBR1502: 30 parts, high styrene emulsion polystyrene butadiene rubber SBR1739: 60 parts, brominated butyl 3745: 10 parts, medium and low specific surface area white carbon black HD1115MP 50 parts, low sulfur silane Joint agent NXT363: 4.4 parts, super wear-resistant carbon black N234: 25 parts, environmentally friendly aromatic oil 10 parts, zinc oxide 3 parts, stearic acid 1.5 parts, phenolic resin ST1101: 5 parts, sulfur 99 (1% oil-extended): 1.7 parts, p-phenylenediamine antioxidant 1.0 parts, protective wax 1.0 parts, accelerator CBS: 1.8 parts, accelerator TS: 0.15 parts, accelerator D: 1.45 parts.

[0043] Put all the rubber into the F370 internal mixer, use the speed of 55RPM to mix for 20 seconds, lift the top bolt, and put all the weighed additives except sulfur and accelerator into the internal mixer through the feeding door and packing delivery pipe for mixing. When the temperature rises to 120°C (considering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com