Boiling-resistant powder coating as well as preparation method and application thereof

A technology of powder coating and water boiling resistance, which is applied in powder coatings, polyester coatings, coatings, etc., to achieve the effect of improving water boiling resistance and reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

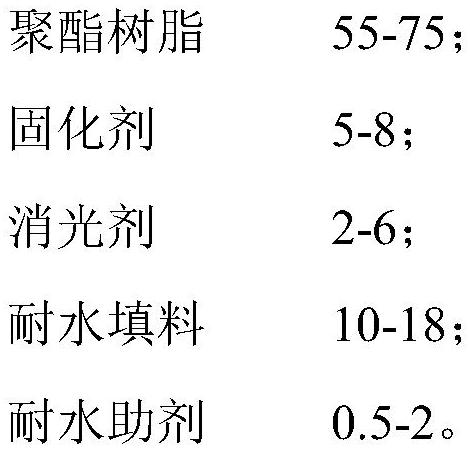

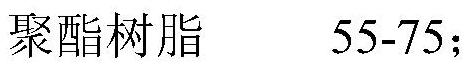

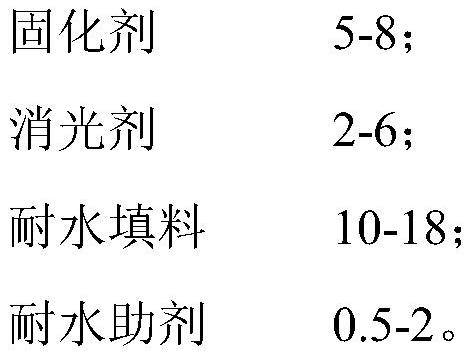

Image

Examples

preparation example Construction

[0041] Secondly, the application also discloses a preparation method of water-resistant powder coating, comprising the following steps:

[0042] Pre-mixing: Weigh the raw materials by weight, put the raw materials into the mixer and mix them evenly. The mixing time is 15-20 minutes to ensure that the matting agent, curing agent and water resistance additive are fully mixed evenly.

[0043] Melt extrusion mixing: The raw materials are melt mixed and extruded with an extruder. Wherein, the extrusion conditions of the extruder are: the temperature of the first zone is 65-75°C, the temperature of the second zone is 75-85°C, and the temperature of the third zone is 75-85°C. This setting facilitates the control of the production gloss.

[0044] The extruded products are pressed into flakes with a tablet machine, crushed with a crusher, crushed with a pulverizer, screened with a rotary sieve to obtain powder coatings, and packed into boxes .

Embodiment 1

[0047] Take by weight the polyester resin of 74 parts by weight, the isocyanate curing agent of 1.5 parts by weight, the hydroxyl curing agent of 5 parts by weight, the matting agent of 4 parts by weight, the leveling agent of 1 part by weight, the benzoin of 0.4 parts by weight, 0.6 parts by weight of polytetrafluoroethylene micro-wax powder, 0.7 parts by weight of carbon black, 10 parts by weight of flaky silicon fillers and 1 part by weight of silane coupling agent; feeding: put the raw materials into the mixer and mix; premix : Use a Misaic mixer to mix the raw materials up and down evenly: Melt extrusion Mixing: Melt and mix the raw materials and extrude them with an extruder; Tabletting: Press the extruded bottom material into a sheet with a tablet machine: Crushing: Use The crusher crushes the flake bottom material; fine crushing: crush the bottom material with a pulverizer; sieve powder packaging: use a rotary sieve to screen the powder coating, and pack the coating int...

Embodiment 2

[0049] The difference from Example 1 is that the addition amount of polyester resin is 72 parts by weight, and the addition amount of flaky silicon filler is 12 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com