High-energy-density slurry fuel, preparation method and application

A high-energy-density, high-density liquid technology, used in fuels, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of oxidative deactivation of nano-aluminum particles, affect energy performance, and reduce active aluminum content, and achieve anti-settling performance. Good, improve combustion performance, reduce the effect of two-phase flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] According to the second aspect of the present invention, there is provided a preparation method of high energy density slurry fuel, comprising the following steps: adding high density liquid hydrocarbon fuel, aluminum base-metal hydride composite Fuel, anti-settling agent, and other performance modifiers are mixed at room temperature to a uniform slurry to obtain a high-energy-density slurry fuel.

[0038] According to the third aspect of the present invention, the use of the high-energy-density slurry fuel described in the first aspect as a fuel for an engine such as a ramjet or a rocket engine.

Embodiment 1

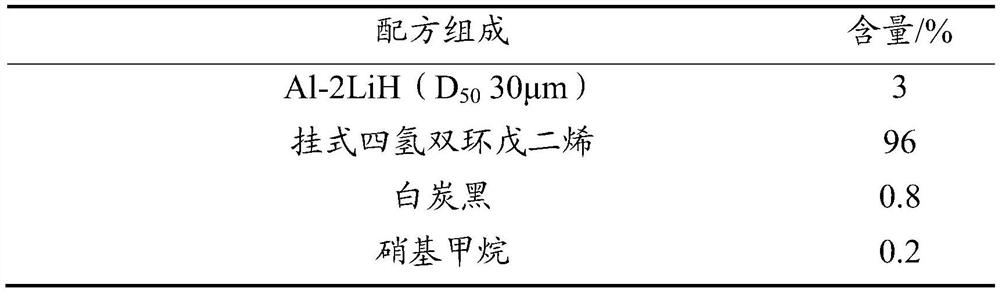

[0042](1) Composition of fuel composition

[0043]

[0044] The preparation method is: add hanging tetrahydrodicyclopentadiene, Al-LiH, white carbon black, and nitromethane into a 5L vertical mixer according to the above ratio, and mix at room temperature for 45 minutes until it becomes a uniform slurry to obtain high-energy Density slurry fuel.

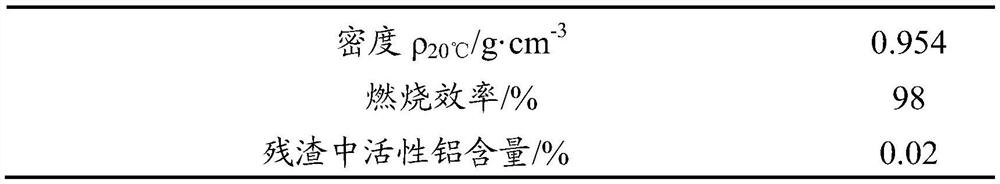

[0045] (2) Fuel performance

[0046]

[0047]

[0048] Can know from embodiment 1, measured calorific value=40.5MJ·kg -1 (greater than 38MJ·kg -1 ), density = 0.954g cm -3 (ρ 20℃ >0.9g·cm -3 ), combustion efficiency = 98%, active aluminum content in the residue = 0.02%, and has the advantages of high density, high energy, fast ignition speed and high combustion efficiency.

Embodiment 2

[0050] (1) Composition of fuel composition

[0051]

[0052] The preparation method is the same as in Example 1.

[0053] (2) Propellant performance

[0054]

[0055] Can know from embodiment 2, measured calorific value=40.9MJ·kg -1 (greater than 38MJ·kg -1 ), density=1.067g cm -3 (ρ 20℃ >0.9g·cm -3 ), combustion efficiency=99%, active aluminum content in the residue=0, and has the advantages of high density, high energy, fast ignition speed and high combustion efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com