Asphalt pavement composite structure and construction method thereof

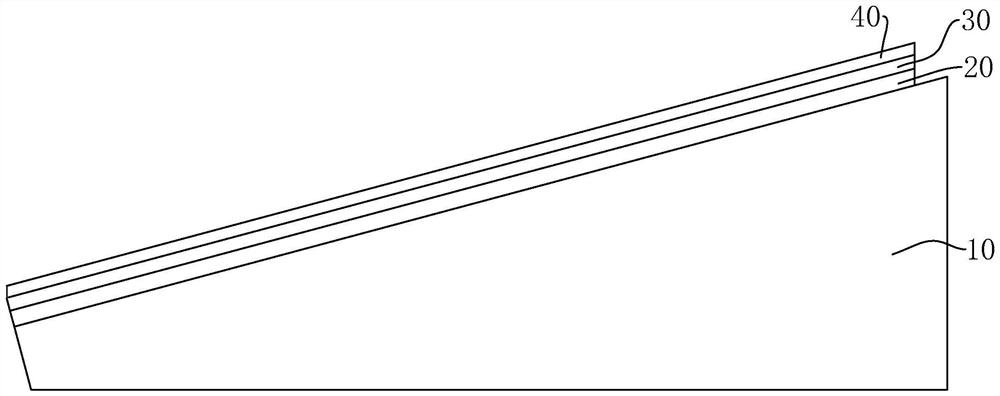

A composite structure and asphalt pavement technology, applied in infrastructure engineering, roads, roads, etc., can solve the problem of uneven thickness, achieve uniform bearing force, improve wildness, and reduce the effect of gravel slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 also discloses a construction method of asphalt pavement composite structure, such as Figure 7 shown, including the following steps:

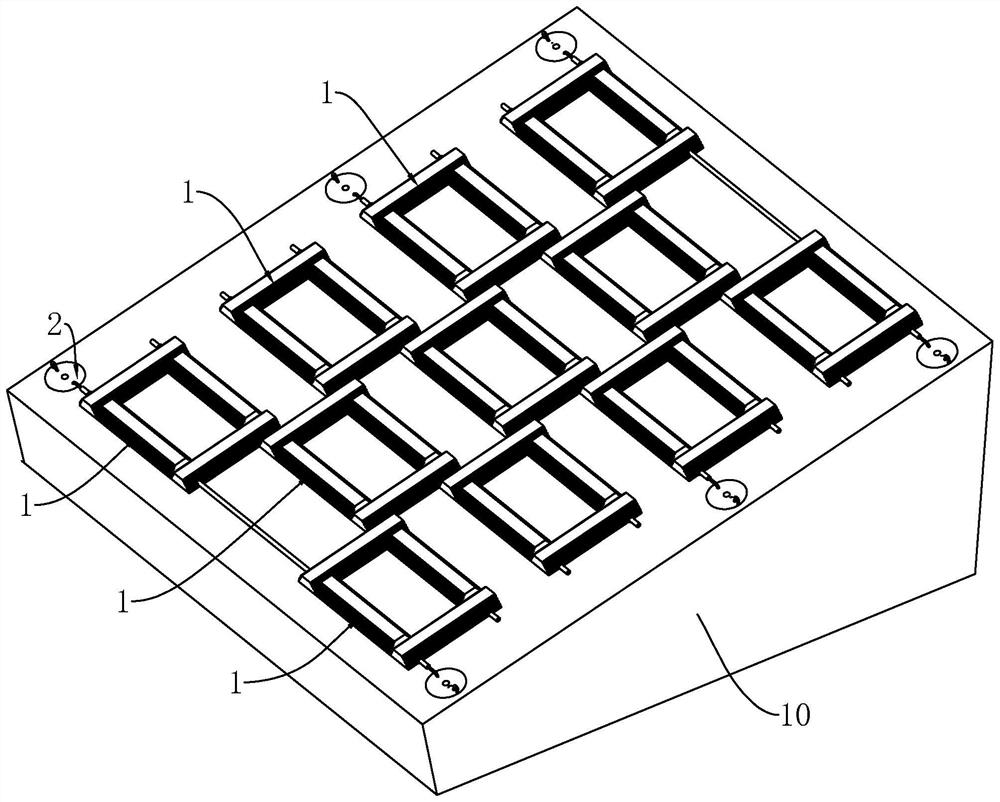

[0058] S1, rolling the inclined roadbed 10: use a road roller to roll the inclined roadbed 10 3 times at a rolling speed of 7-10 meters per minute to improve surface smoothness.

[0059] S2. Positioning and marking: use lime powder to draw lines along the width of the inclined roadbed 10 to determine the position of the steel pipe 21 .

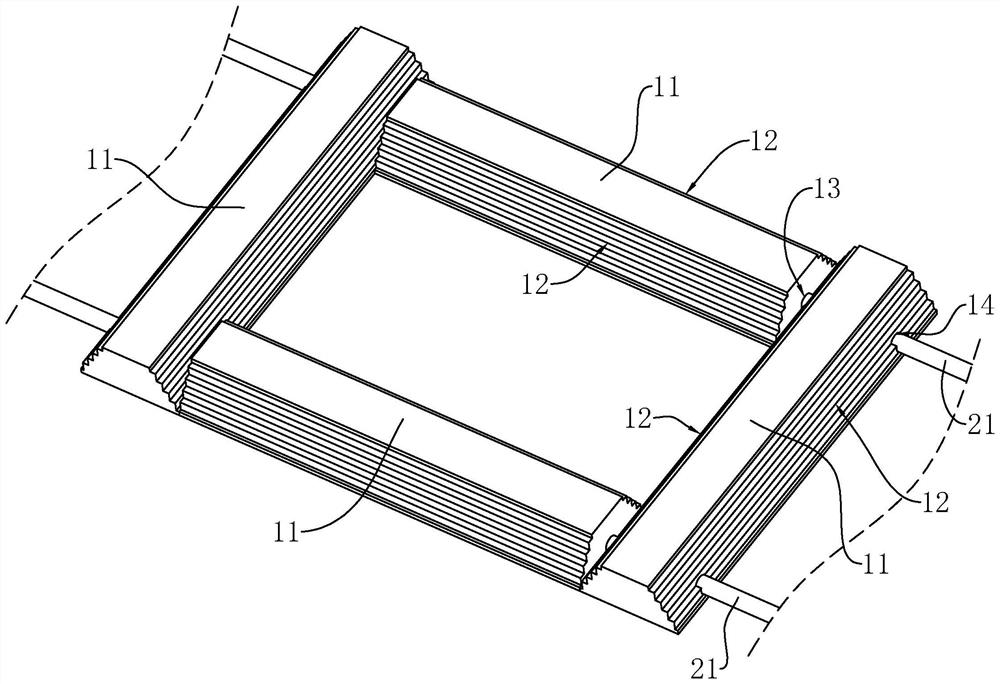

[0060] S3. Paving the blocking frame 1: Pre-arrange the position of the blocking frame 1 according to the marking position, and then pre-shape the blocking frame 1 by piercing the steel pipe 21 to ensure the control of the blocking frame 1 Neatly, then press the blocking frame 1 to ensure that the blocking frame 1 fits the surface of the inclined roadbed 10, and then tighten the limit ring 211 so that the limit ring 211 is tight against the outside of the blocking frame 1, and the blocking...

Embodiment 2

[0065] Embodiment 2, make the following setting on the basis of embodiment 1, such as Figure 8 As shown, there is a notch at the center of the upper part of the first blocking strip, the notch is strip-shaped, and the length direction of the notch is set along the length direction of the inclined roadbed 10, and the notch goes deep into the first perforation 13, which is the first water passage Hole 15, steel pipe 21 is provided with the second water hole (not marked among the figure), and the second water hole is communicated with the first water hole 15, and the two ends of steel pipe 21 are connected with drainage pipe 27, and drainage pipe 27 uses In connection with the groundwater delivery system.

[0066] When there is accumulated water in the base layer 20, the accumulated water will pass through the first bucket water hole, the second water hole, the steel pipe 21 in sequence, and finally be discharged into the underground transportation system by the drain pipe 27, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com