Reinforcing method for high-speed railway karez foundation

A technology for high-speed railways and foundations, applied in infrastructure engineering, applications, household appliances, etc., can solve problems such as large project investment, long bridge length, and elevation, and achieve the effects of ensuring safe operation, improving strength, and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

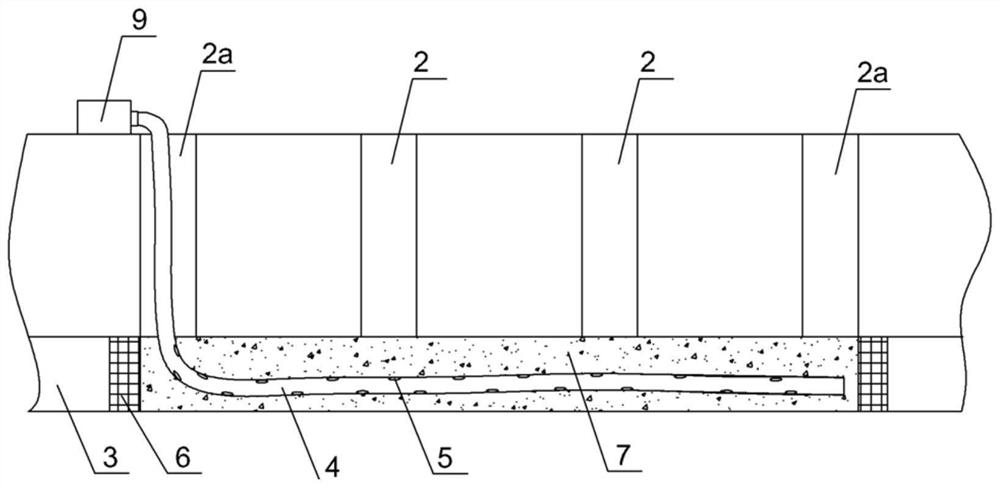

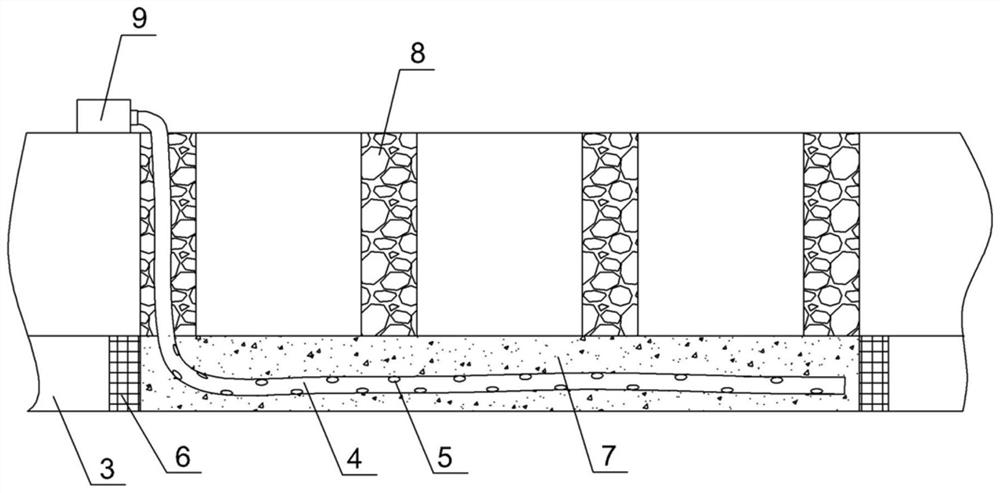

[0032] figure 1 , figure 2 Shown, a kind of embodiment of the present invention is, a kind of reinforcement method of high-speed railway Karez foundation, comprises the following steps:

[0033] A. Buried slurry interception barrier

[0034] The vertical wells at both ends of the culvert section 3 under the high-speed railway embankment to be reinforced in the Karez foundation are used as the boundary shaft 2a; on the outside of the boundary shaft 2a and the junction, a slurry interception barrier 6 composed of multi-layer geotextiles is buried.

[0035] B. Set the grouting pipe

[0036] Connect the beginning end of the grouting pipe 4 with the high-pressure grouting pump 9 on the ground, and the tail end of the grouting pipe 4 extends from a boundary shaft 2a into the underdrain 3 and reaches another boundary shaft 2a; and the grouting pipe 4 is located in the underdrain A plurality of grouting holes 5 are opened on the pipe wall in 3;

[0037] C. Preparation of slurry ...

Embodiment 2

[0044] A method for strengthening the Karez foundation of a high-speed railway, comprising the following steps:

[0045] A. Buried slurry interception barrier

[0046] The vertical wells at both ends of the culvert 3 section under the high-speed railway subgrade to be reinforced in the Karez foundation are used as the boundary shaft 2a; on the outside of the boundary shaft 2a and the junction, a slurry interception barrier 6 composed of multi-layer glass fiber mesh cloth is buried ;

[0047] B. Set the grouting pipe

[0048] Connect the beginning end of the grouting pipe 4 with the high-pressure grouting pump 9 on the ground, and the tail end of the grouting pipe 4 extends from a boundary shaft 2a into the underdrain 3 and reaches another boundary shaft 2a; and the grouting pipe 4 is located in the underdrain A plurality of grouting holes 5 are opened on the pipe wall in 3;

[0049] C. Preparation of slurry

[0050] The label of 250 parts of quality is the ordinary portlan...

Embodiment 3

[0056] A method for strengthening the Karez foundation of a high-speed railway, comprising the following steps:

[0057] A. Buried slurry interception barrier

[0058] The vertical wells at both ends of the culvert 3 section under the high-speed railway subgrade to be reinforced in the Karez foundation are used as the boundary shaft 2a; on the outside of the boundary shaft 2a and the junction, a slurry interception barrier 6 composed of multi-layer glass fiber mesh cloth is buried ;

[0059] B. Set the grouting pipe

[0060] Connect the beginning end of the grouting pipe 4 with the high-pressure grouting pump 9 on the ground, and the tail end of the grouting pipe 4 extends from a boundary shaft 2a into the underdrain 3 and reaches another boundary shaft 2a; and the grouting pipe 4 is located in the underdrain A plurality of grouting holes 5 are opened on the pipe wall in 3;

[0061] C. Preparation of slurry

[0062] The label of 350 parts of quality is the ordinary portlan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com