Micro-channel device for heat dissipation of high-power semiconductor chip and processing method

A chip heat dissipation and processing method technology, which is applied to semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as low thermal conductivity, overheating and burning of chips, and high pressure requirements of water pump systems to ensure thermal conductivity. , Material consistency is good, the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

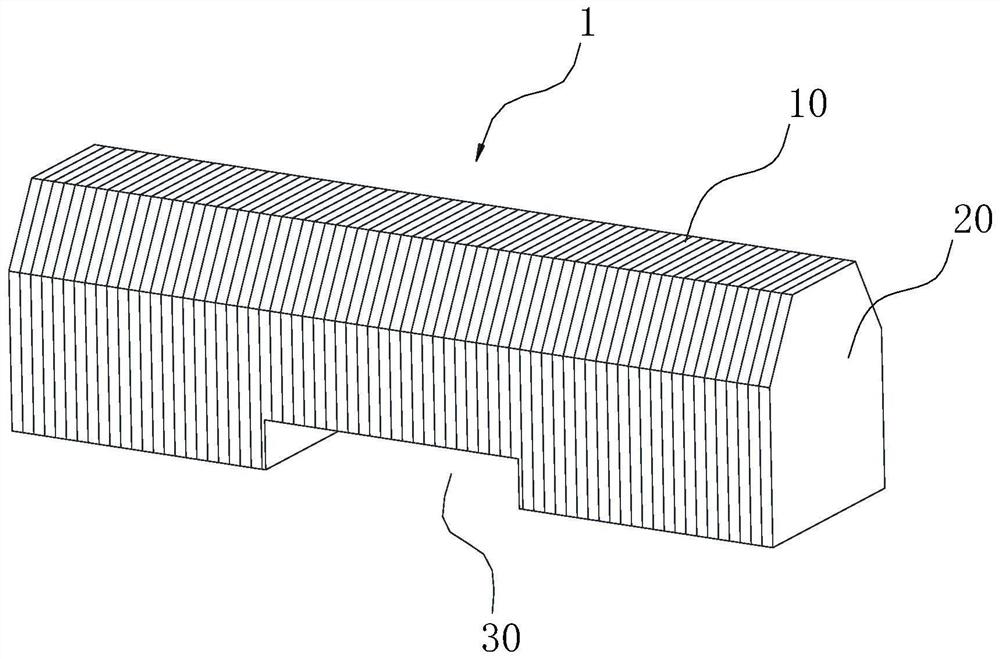

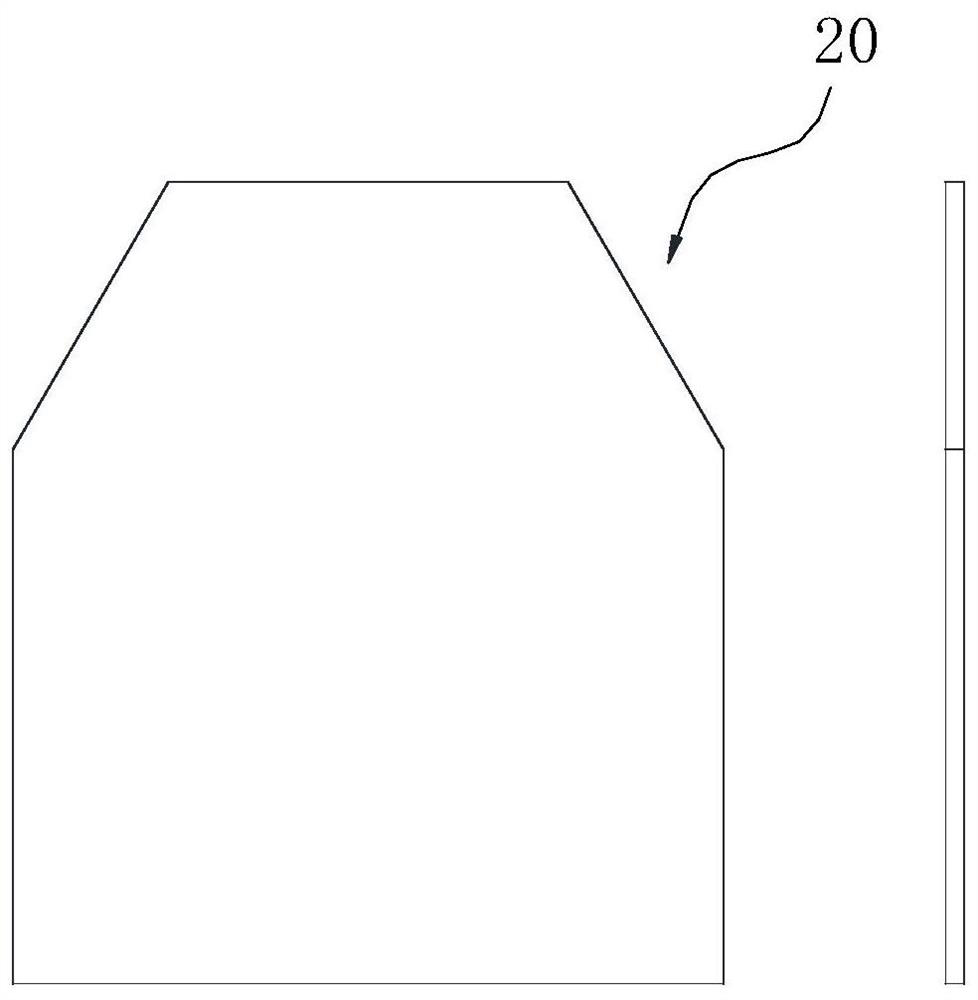

[0053] Such as figure 1 , Figure 3-5 Shown, a kind of microchannel device 1 that is used for the heat dissipation of high-power semiconductor chip, comprises the heat dissipation inner core that is formed by the staggered arrangement of several heat dissipation fins 10 and the blocking sheet 20 that is arranged on the front and rear ends of the described heat dissipation inner core; Heat dissipation fin 10 and The blocking pieces 20 are in the shape of a hexagon including two adjacent right angles and four inner obtuse angles, and the shape of the cooling fins 10 enables the microchannel device to avoid adjacent components during installation. The heat sink 10 and the blocking sheet 20 are both made of oxygen-free copper, and both have a thickness of 0.3 mm. The center of the bottom of the micro-channel device 1 is also provided with a groove 30 for positioning and installation. The groove 30 is as wide as the micro-channel device 1 but slightly shorter in length.

[0054] ...

Embodiment 2

[0062] A processing method for a microchannel device 1 for heat dissipation of a high-power semiconductor chip, the steps are as follows:

[0063] S1. Positioning on the oxygen-free copper plate and chemically etching out the hollow groove required for the heat sink 10, and then cutting the etched oxygen-free copper plate into the required heat sink 10;

[0064] S2. cutting the unetched oxygen-free copper plate to obtain the blocking sheet 20;

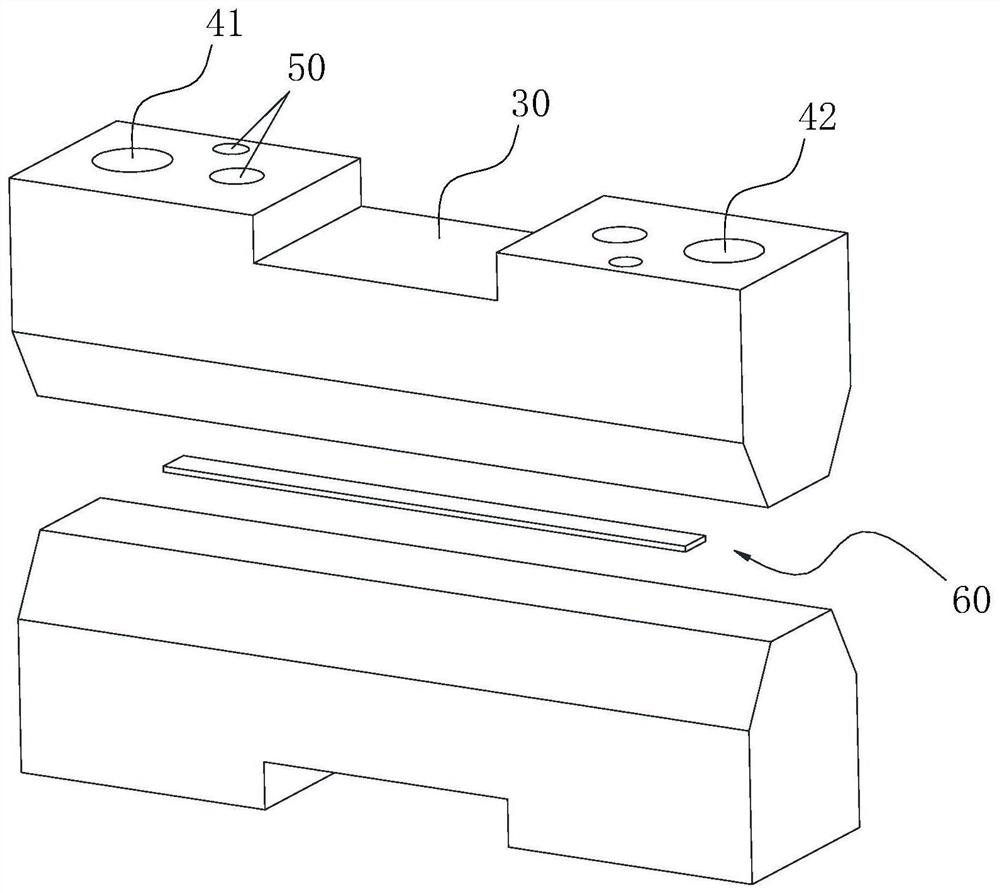

[0065] S3. Place the blocking sheet 20 on the fixture, then place the cooling fins 10 according to the required stacking order and quantity of the cooling fins 10, and finally place the blocking sheet 20 at the end;

[0066] S4. Put the arranged heat sink 10 together with the fixture into a diffusion welding furnace for diffusion welding, and the welding temperature is 900°C-1100°C;

[0067] S5. The welded product is subjected to secondary cutting, and the groove 30 is processed to obtain the final desired shape of the microchannel de...

Embodiment 3

[0073] Utilize the microchannel device prepared by the present invention to compare with the cooling device that changes the shape of the microchannel in the device. The appearance and material of the microchannel cooling device for comparison are consistent with the microchannel device prepared by the present invention, but its water flow channel is integrally processed. into, respectively, a rhombus straight and a rectangular straight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com