Sensor power supply management system and method

A power supply management and sensor technology, which is applied in the direction of instruments, electrical components, speed/acceleration/electric shock meter details, etc., can solve the problems of large standby current and standby time, increase the standby power consumption of MEMS sensors, etc., and achieve convenient production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

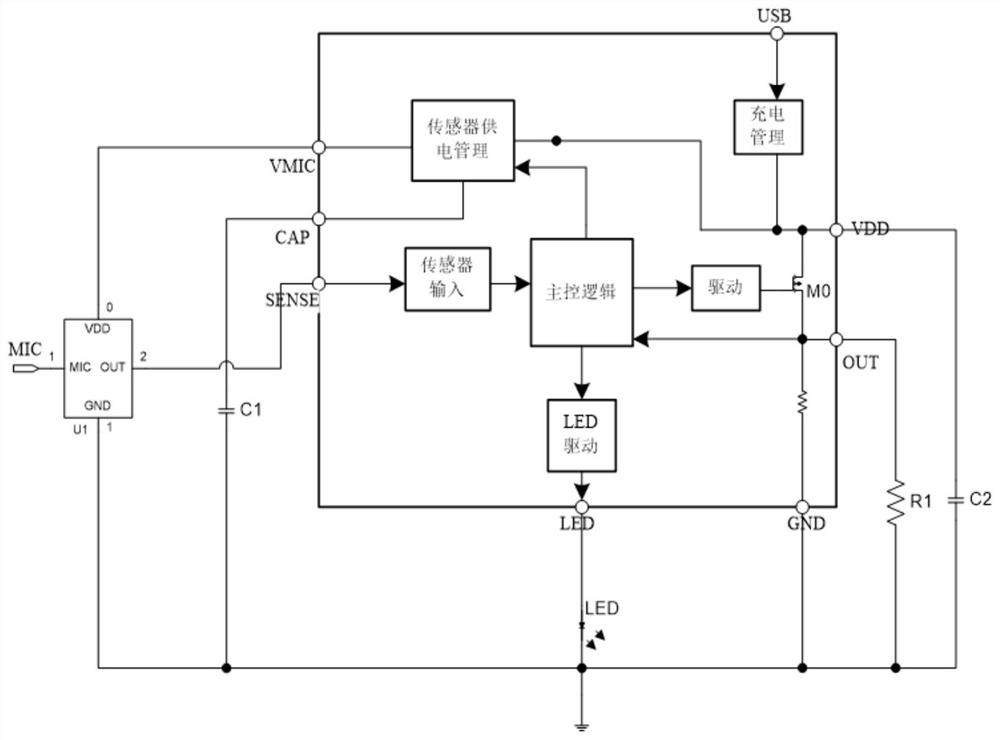

[0051] like figure 2 As shown, U1 is a MEMS sensor, which is a device for detecting sound or airflow; U2 is a chip that integrates MEMS sensor power supply management, heating wire heating, LED indication and battery charging management, wherein the present invention proposes a MEMS sensor power supply management module. .

[0052] MEMS sensor U1 is provided with air inlet MIC, pins: GND, OUT, VDD; chip controller U2 is provided with pins VMIC, CAP, SENSE, GND, OUT, LED, VDD, USB;

[0053] The air inlet MIC of the MEMS sensor U1 inputs the MIC signal, the pin VDD of U1 is connected to the pin VMIC of U2, the pin OUT of U1 is connected to the pin SENSE of U2; the pin CAP of U2 is connected to the capacitor C1, and the tube of U2 is connected The pin VDD is connected to the battery C2, the pin LED of U2 is connected to the light emitting diode LED, the pin OUT of U2 is connected to the resistor R1; the pin GND of U1, the pin GND of the capacitor C1, the pin GND of U1, the resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com