Modified powder and preparation method thereof, and cosmetic containing modified powder

A technology of modified powder and cosmetics, which is applied in the field of modified powder and its preparation, and the field of modified powder cosmetics, which can solve the problems of cosmetic formula design restrictions, decreased compatibility between powder and oil, and high oil absorption value. , to achieve the effect of excellent long-lasting makeup, excellent compatibility and moderate oil absorption value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing the modified powder, comprising:

[0043] S1, provide basic powder;

[0044] S2, under the condition of stirring, mix perfluoropolyether and fluorosilane with the basic powder to obtain a mixture, wherein the mass of the perfluoropolyether and the fluorosilane are both the mass of the basic powder 0.5%-10% of mass;

[0045] S3, drying the mixture at 90°C-130°C to obtain a modified powder.

[0046] In step S2, in the step of mixing perfluoropolyether and fluorosilane with the base powder: the perfluoropolyether and the fluorosilane can be mixed with the base powder at the same time; Mix the perfluoropolyether with the base powder to obtain an intermediate product, then mix the fluorosilane with the intermediate product to obtain the mixture; or first mix the fluorosilane with the base powder An intermediate product is obtained, and the perfluoropolyether is mixed with the intermediate product to obtain the mix...

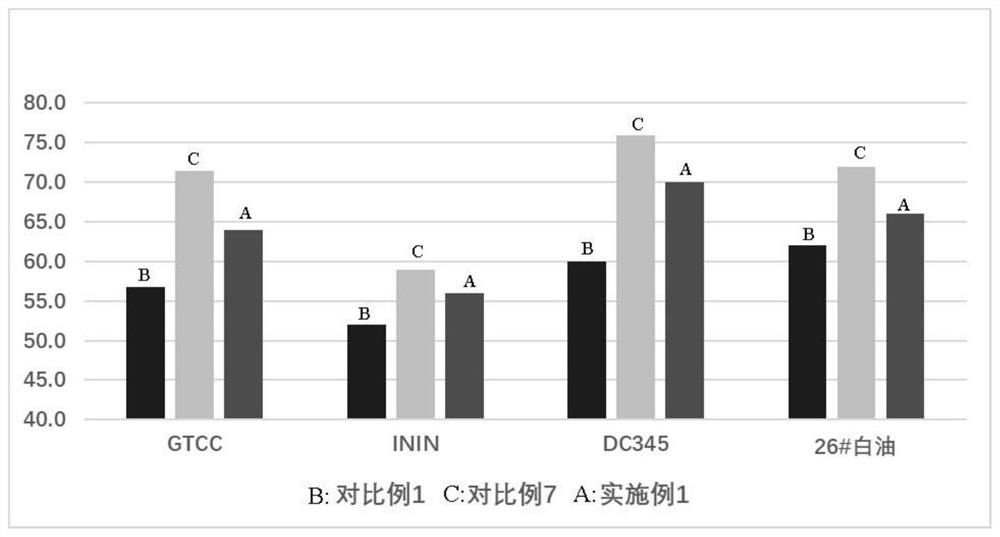

Embodiment 1

[0053] Use a high-speed mixer to stir 10kg of talcum powder. Under the condition of high-speed stirring, use an oil spray tank to spray 200g of polyperfluoromethyl isopropyl ether into the high-speed mixer, and mix it with talcum powder to obtain an intermediate product. Fluoroctyltriethoxysilane was sprayed into a high-speed mixer, mixed evenly with the intermediate product to obtain a mixture, and finally the mixture was dried at 105°C for 2 hours and cooled naturally to obtain modified talc powder.

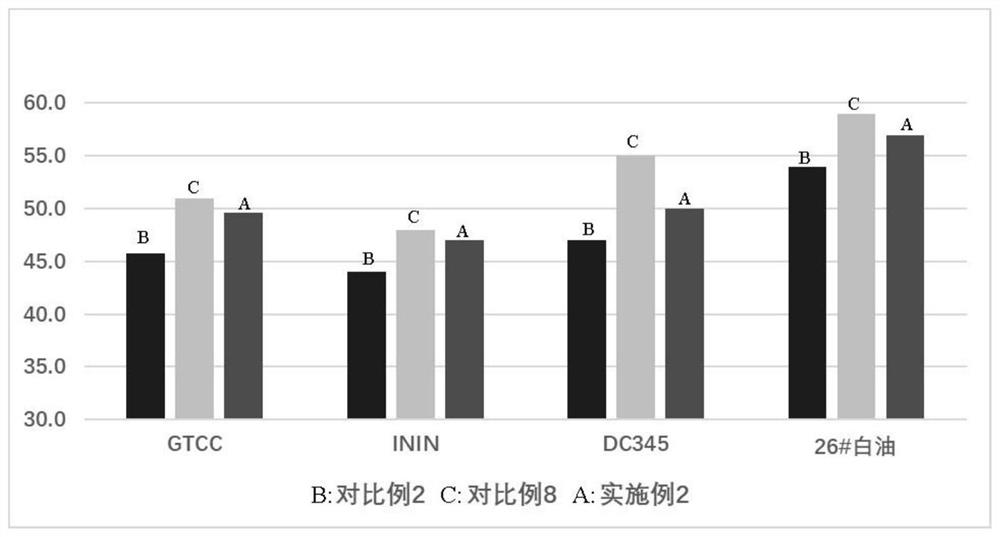

Embodiment 2

[0055] Use a high-speed mixer to stir 10kg of mica. Under the condition of high-speed stirring, use an oil spray tank to spray 200g of polyperfluoromethyl isopropyl ether into the high-speed mixer, and mix it with mica evenly to obtain an intermediate product. Then add 200g of perfluorooctyl The base triethoxysilane was sprayed into a high-speed mixer, mixed evenly with the intermediate product to obtain a mixture, and finally the mixture was dried at 105°C for 2 hours, and cooled naturally to obtain modified mica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com