One-bag type plugging agent and preparation method thereof

A plugging agent and bag-type technology, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well parts, etc., can solve the problems of increased drilling costs, large particle sealing, no strength, etc., and achieves plugging technology Advanced and mature, fast and convenient processing, and the effect of saving well site space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

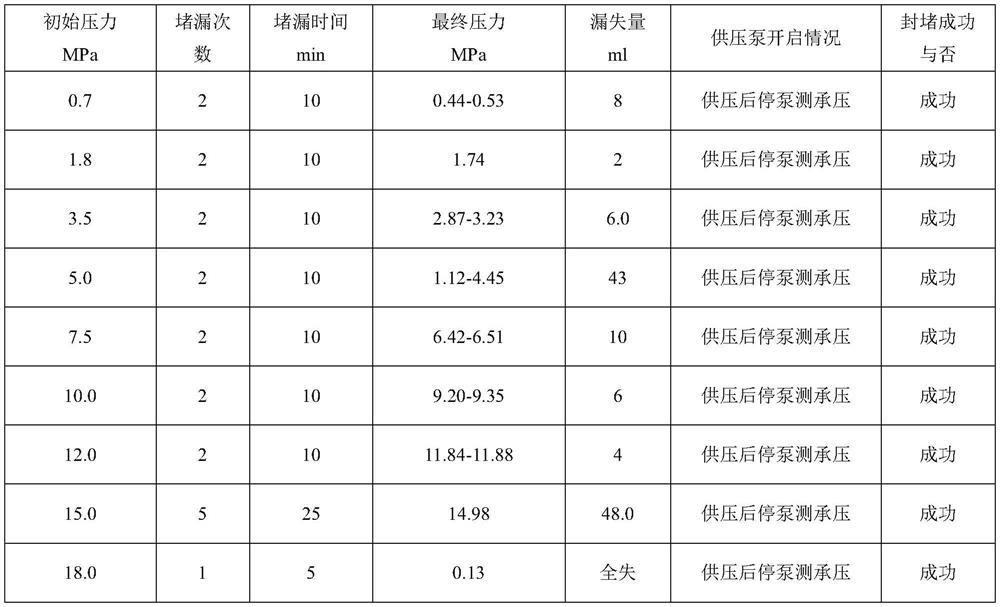

Examples

Embodiment 1

[0023] The invention provides a one-bag plugging agent, all the components are arranged in a sealed packaging bag, and each component can be sealed in the sealed bag under normal temperature and pressure, and will not react with each other. After sealing, it can be used after treatment. The one-bag plugging agent includes the following components: 5 parts of compressible elastic sealing agent, 5 parts of mica sheet, 15 parts of mineral fiber, 3 parts of cotton seed, plant 15 parts of fiber, 15 parts of inorganic blocking agent, 20 parts of bridging agent, the compressible elastic sealing agent includes 20 parts of natural rubber, 3 parts of biopolymer, 3 parts of calcium carbonate, the The average density is 2.4-3.0g / cm 3 , the average particle size is 0.5-5mm, the preparation method of the inorganic plugging agent is as follows: mica sheet, expansive vermiculite, shell fragments are mixed uniformly by mass ratio 1:1:(1-3), after crushing and screening, Obtain an inorganic bl...

Embodiment 2

[0030] The invention provides a one-bag plugging agent, all the components are arranged in a sealed packaging bag, and each component can be sealed in the sealed bag under normal temperature and pressure, and will not react with each other. After sealing, it can be used after treatment. The one-bag plugging agent includes the following components: 7 parts of compressible elastic sealing agent, 6 parts of mica sheet, 19 parts of mineral fiber, 6 parts of cotton seed, plant 20 parts of fiber, 20 parts of inorganic blocking agent, 25 parts of bridging agent, the compressible elastic sealing agent includes 25 parts of natural rubber, 4 parts of biopolymer, 4 parts of calcium carbonate, the inorganic blocking agent The average density is 2.4-3.0g / cm 3 , the average particle size is 0.5-5mm, the preparation method of the inorganic plugging agent is as follows: mica sheet, expansive vermiculite, shell fragments are mixed uniformly by mass ratio 1:1:(1-3), after crushing and screening...

Embodiment 3

[0037] The invention provides a one-bag plugging agent, all the components are arranged in a sealed packaging bag, and each component can be sealed in the sealed bag under normal temperature and pressure, and will not react with each other. After sealing, it can be used after treatment. The one-bag plugging agent includes the following components: 10 parts of compressible elastic sealing agent, 8 parts of mica sheet, 22 parts of mineral fiber, 8 parts of cotton seed, plant 25 parts of fiber, 25 parts of inorganic blocking agent, 30 parts of bridging agent, said compressible deformable elastic blocking agent includes 30 parts of natural rubber, 5 parts of biopolymer, 5 parts of calcium carbonate, the inorganic blocking agent The average density is 2.4-3.0g / cm 3, the average particle size is 0.5-5mm, the preparation method of the inorganic plugging agent is as follows: mica sheet, expansive vermiculite, shell fragments are mixed uniformly by mass ratio 1:1:(1-3), after crushing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com