Method for predicting blockage of air pre-heater

A prediction method and air preheater technology, applied in combustion methods, instruments, lighting and heating equipment, etc., can solve the problems of neglecting the optimization and prevention of air preheater blockage, the strong viscosity of liquid ammonium hydrogen sulfate, affecting the output of the unit, etc. Achieve the effect of saving resources and operating costs, reducing the generation of corrosion, and extending the life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

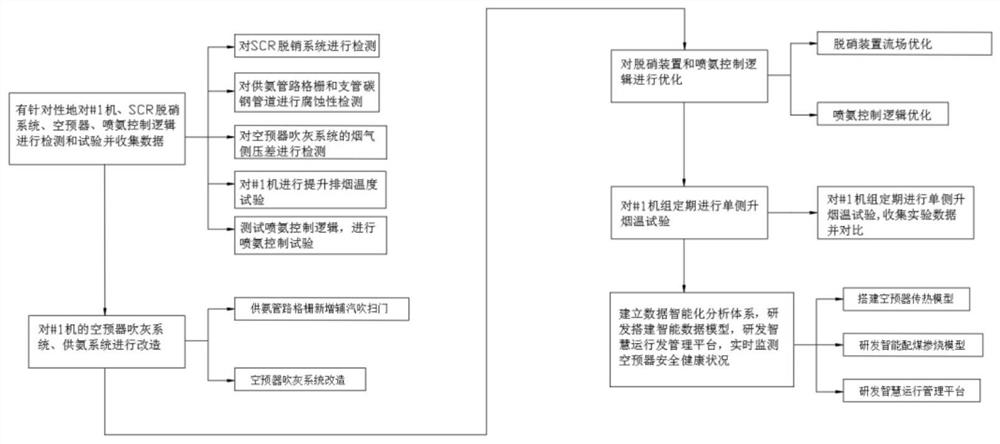

[0053] refer to Figure 1-2 , a method for predicting air preheater clogging, comprising the following steps:

[0054] Test #1 unit, SCR denitrification system, air preheater, and ammonia injection control logic through experiments to collect data;

[0055] By transforming the single-pass soot blower into a double-pass soot blower, and installing steam pipes for blowing scale at each ammonia supply grid, the air preheater soot blowing system and ammonia supply system of #1 machine can be realized. adjustment work;

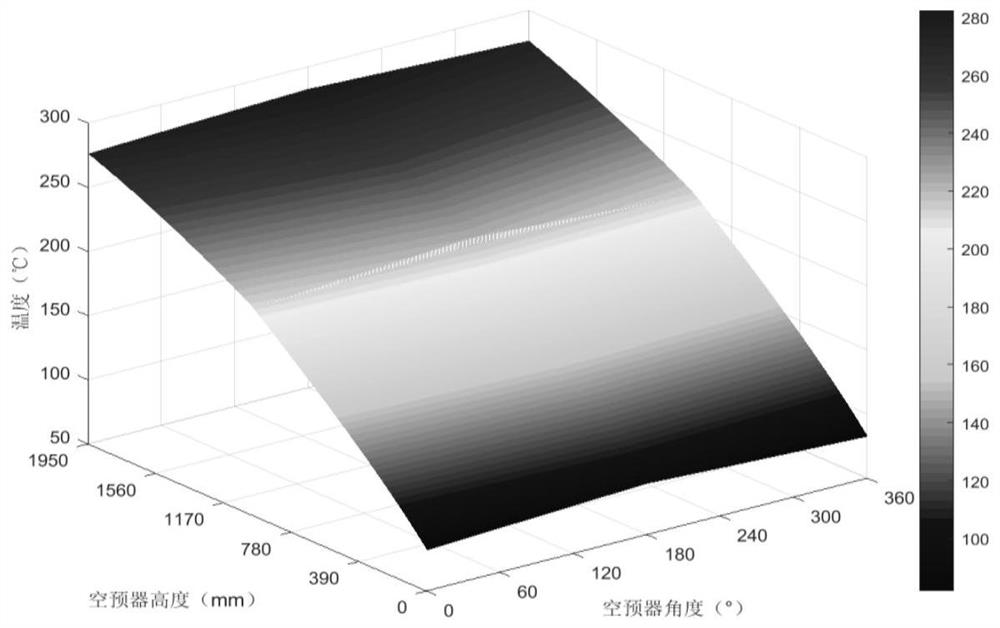

[0056] The denitrification reaction in the process of air flow is fully realized through the guide plate set on the top of the denitrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com