New rare earth power supply negative electrode slurry and slurry process

A power supply negative electrode and rare earth technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as the inability to achieve uniform mixing of large-capacity slurry, achieve controllable production time, reliable quality, and reduce batches and work shifts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

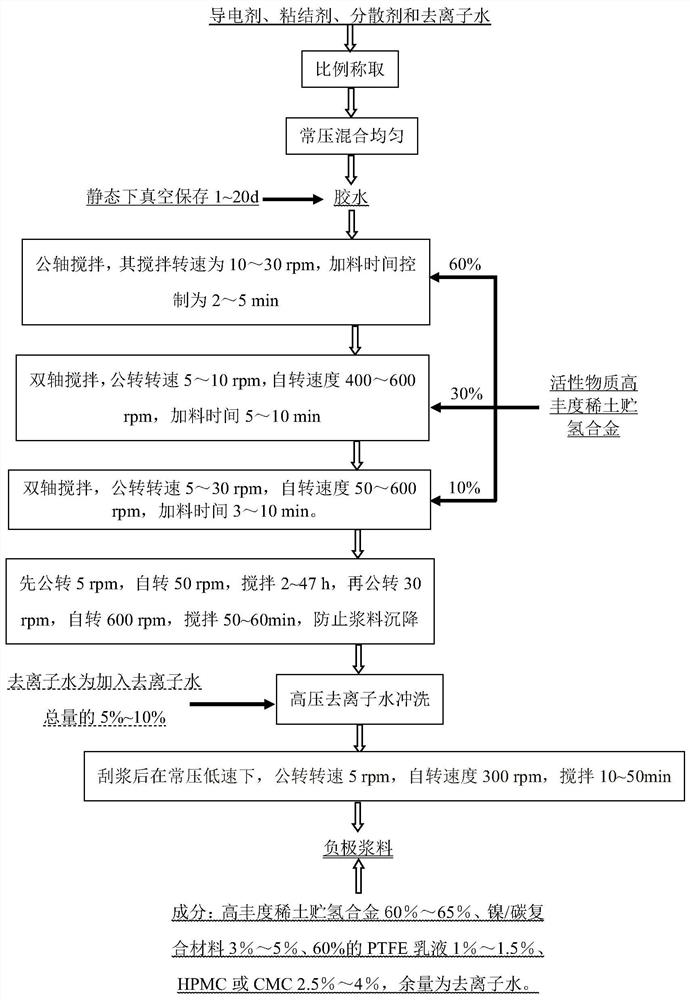

Method used

Image

Examples

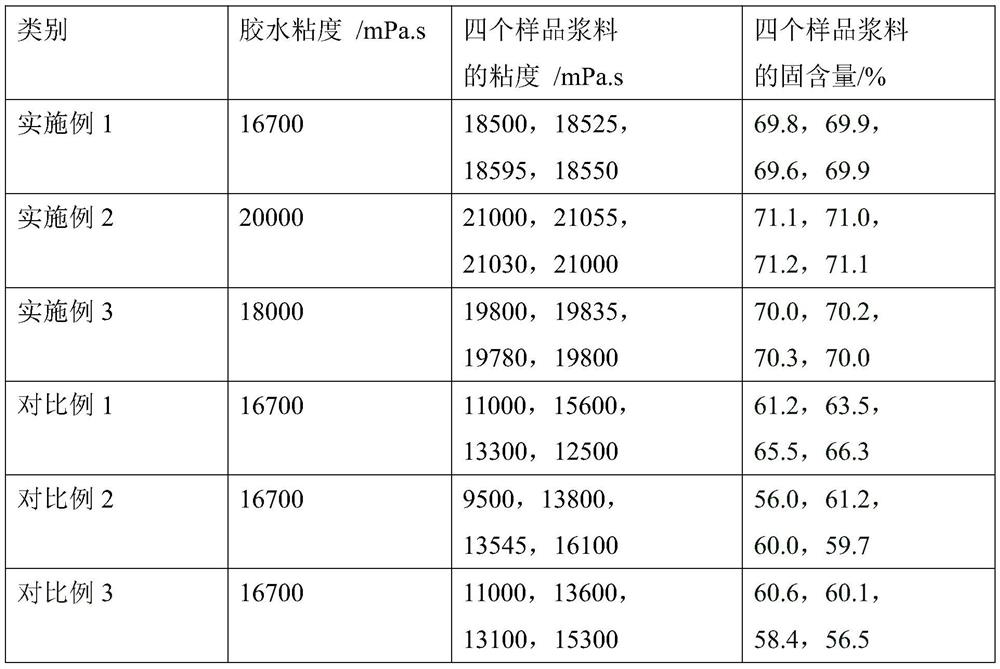

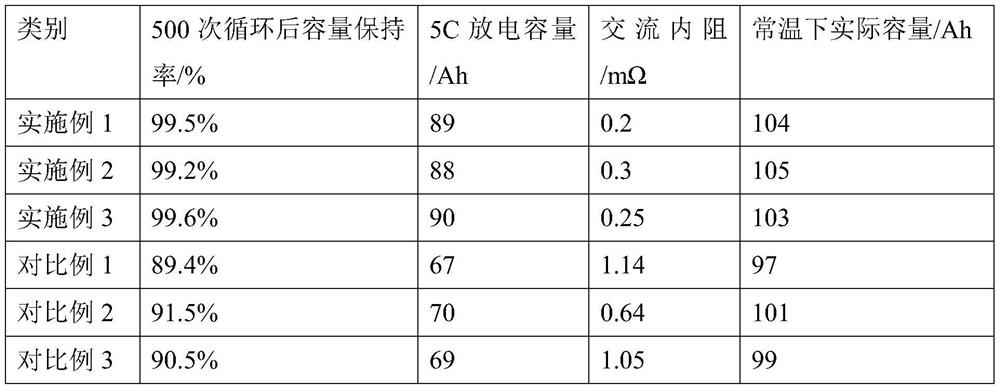

Embodiment 1

[0036] A rare earth new power supply negative slurry and pulp process, including the following steps:

[0037] (1) Configuring raw materials, each composition in the slurry is included in mass: active substance: high-stricken rare earth hydrogen storage alloys, conductive agent: nickel / carbon composite material, dispersant: 60% PTFE emulsion 1% , Binder: HPMC2.5%, margin is deionized water, weighing raw materials in proportion.

[0038] (2) The binder HPMC with deionized water (95% deionized water having a total weight of ion water) is mixed in a vacuum stirrer, and then the conductive agent nickel / carbon composite material is added. Using normal pressure at normal pressure, high-speed stirring is uniform, then add the dispersant, and the low speed is mixed in normal pressure at normal pressure, and the mixing is mixed, and the glue is obtained; in a static negative pressure vacuum Lower (vacuum reaching 15% lower than the outer standard air pressure).

[0039] (3) After the s...

Embodiment 2

[0046] A rare earth new power supply negative slurry and pulp process, including the following steps:

[0047] (1) Configuring raw materials, each composition in the slurry is included in mass: active substance: high-defensive rare earth hydrogen storage alloy, conductive agent: nickel / carbon composite material, dispersant: 60% PTFE emulsion 1.5% , Adhesive: CMC4%, margin is deionized water, weighing raw materials in proportion.

[0048] (2) The binder CMC with deionized water (90% of the total weight of the total weight of ion water) is mixed in a vacuum stirrer, and then the conductive agent nickel / carbon composite is added. High-speed stirring dispersion is uniform at normal pressure, and then add a dispersant, and the low speed is mixed in the normal pressure of 25 m / s under normal pressure to obtain a glue; in a static negative pressure vacuum The lower (vacuum is reached to 10% less than 10% of the outer standard air pressure).

[0049] (3) After the step (2), three ad...

Embodiment 3

[0056] A rare earth new power supply negative slurry and pulp process, including the following steps:

[0057] (1) Configuring raw materials, each composition in the slurry is included in mass: active substance: high-defensive rare earth hydrogen storage alloy 62.5%, conductive agent: nickel / carbon composite material, dispersant: 60% PTFE emulsion 1.25% , Binder: HPMC 3%, margin is deionized water, weighing raw materials in proportion.

[0058] (2) The binder HPMC with deionized water (92% of the total weight of the total weight of ion water) is mixed in a vacuum stirrer, then add a conductive agent nickel / carbon composite material. At normal pressure, high-speed stirring dispersion is uniform with a line speed of 35 m / s, and then add the dispersant. Under normal pressure, the low speed is mixed in the normal pressure, and the glue is obtained; in a static negative pressure vacuum The lower (vacuum reached 20% less than 20% of the outer standard air pressure).

[0059] (3) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com