Refining method of didrogesterone

A refining method and technology of dydrogesterone, applied in the direction of steroids, organic chemistry, etc., can solve the problems that peroxides are easy to be dangerous and difficult to remove.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]

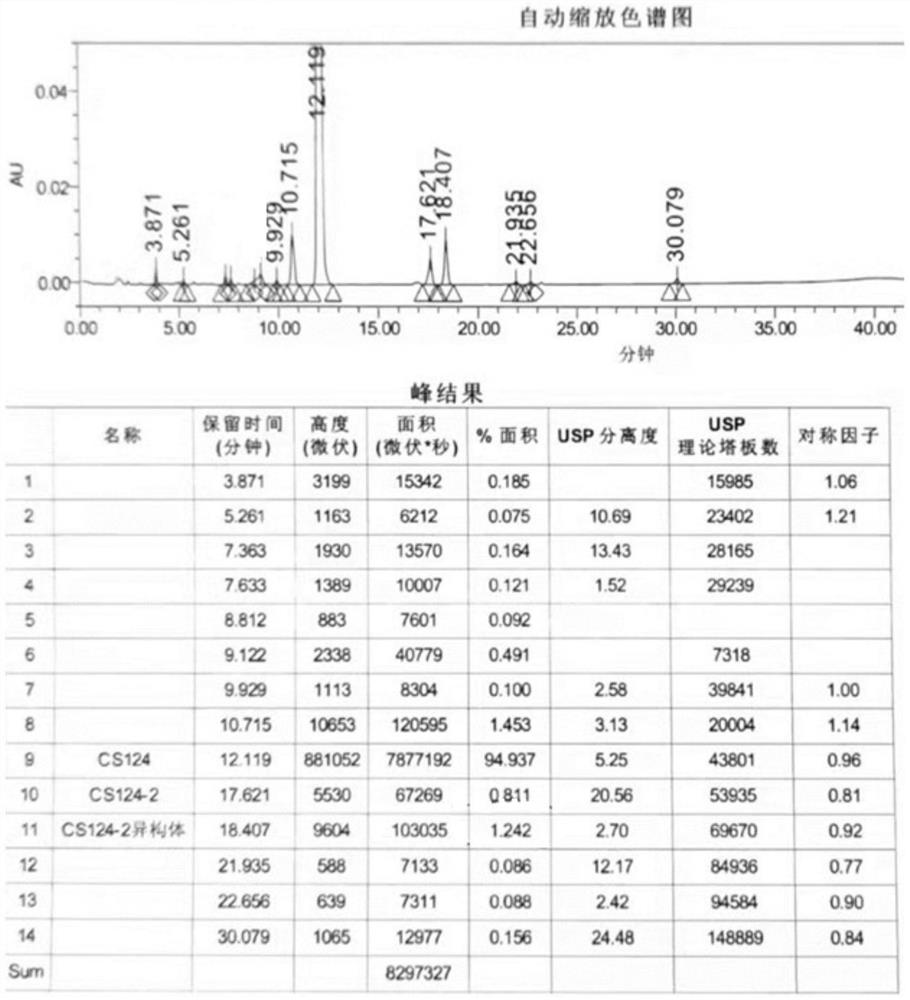

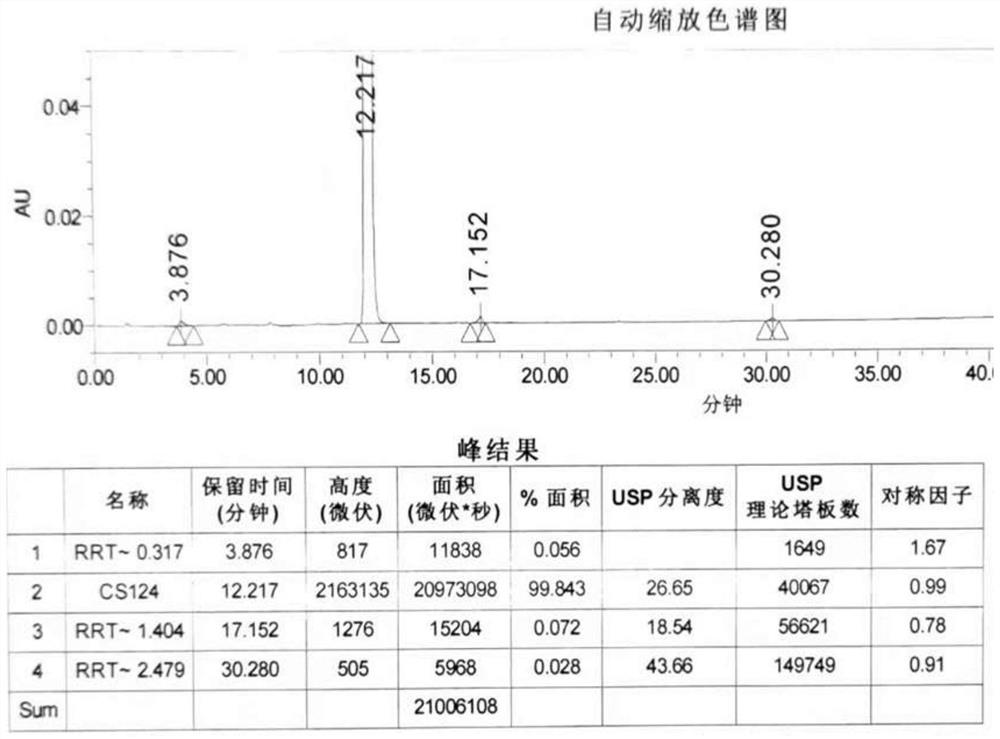

[0026] 20g crude dydrogesterone (purity 94.9%, aldehyde impurity content 2.1%, see figure 1 ) into the reaction bottle with magnetron, add 100mL of dichloromethane and stir to dissolve, add 40mL of water, 6g of sodium bisulfite, continue to stir vigorously, insert the ultrasonic launch rod of the ultrasonic reflector below the liquid level, and start the ultrasonic reaction The instrument was stirred at room temperature (25-30 °C) for 2 h. Pour out the reaction solution, let stand for stratification, and separate the layers. Add 50 mL of water to the organic layer, stir to separate the layers, add 50 mL of water again, concentrate dichloromethane to dryness, add acetone to recrystallize, crystallize at -5 to 0 °C, and filter, Dried dydrogesterone fine product, the purity is 99.84%, the sum of the content of aldehyde group impurity 1 and impurity 2 is less than 0.1%, specifically 0.072%, see figure 2 .

Embodiment 2

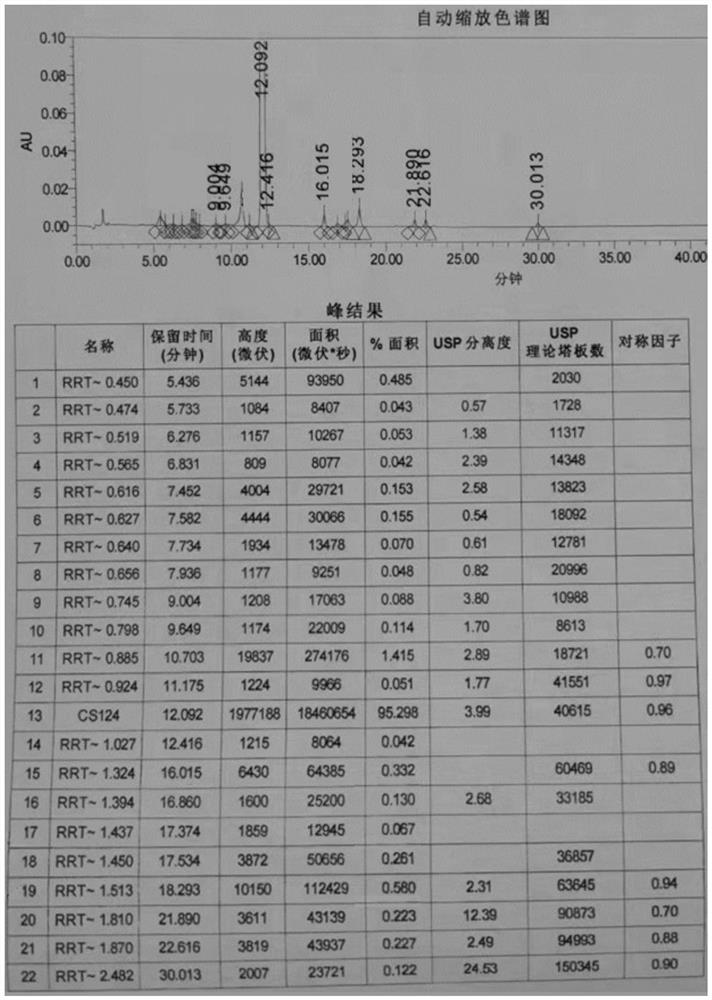

[0028] 20g crude dydrogesterone (purity 94.93%, aldehyde group impurity content 2.1%) was added to a reaction flask with a magnet, 100mL of dichloromethane was added and stirred to dissolve, 50mL of water and 6g of sodium metabisulfite were added, and vigorous stirring was continued. Insert the ultrasonic transmitting rod of the reflector below the liquid level, turn on the ultrasonic reactor, and stir for 2 hours at room temperature (25-30°C). Pour out the reaction solution, let stand for stratification, separate the layers, add 50 mL of water to the organic layer, stir to separate the layers, add 50 mL of water again, concentrate dichloromethane to dryness, add acetone for recrystallization, crystallize at -5 to 0 °C, filter, The fine dydrogesterone is obtained by drying, the purity is 99.82%, and the sum of the content of aldehyde group impurity 1 and impurity 2 is less than 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com