Underfill material and preparation method and application thereof

A technology of inorganic filler and epoxy resin, which is applied in the field of underfill materials and its preparation, and can solve problems such as poor reworkability, low Tg, and long curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the underfill material provided by the invention includes uniformly mixing each component to obtain the underfill material. The present invention has no special limitation on the way of mixing the components uniformly. In a preferred embodiment, the way of mixing uniformly is to add catalyst and optional silane coupling agent, stabilizer and inorganic filler to epoxy and uniformly dispersed in the resin to obtain an epoxy resin compound; adding a thiol compound to the epoxy resin compound and uniformly dispersed to obtain an underfill material. Wherein, the types and amounts of each component have been described above, and will not be repeated here.

[0033] The invention also provides the application of the underfill material in underfill for chips and PCB boards.

Embodiment 1

[0035] Embodiment 1 (equivalent ratio 0.01)

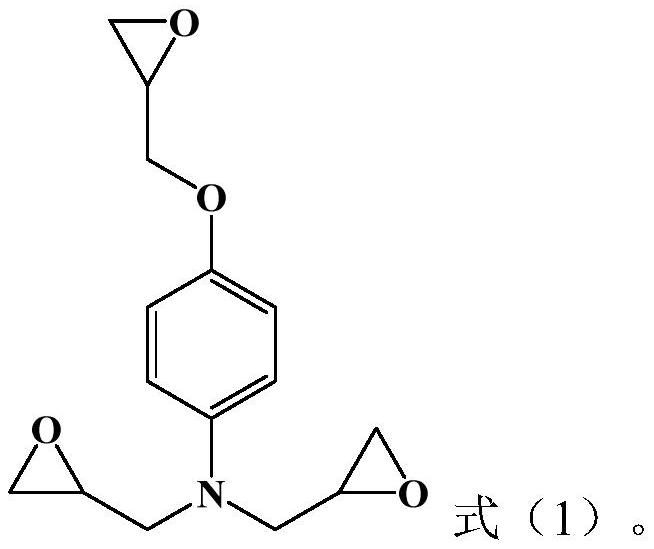

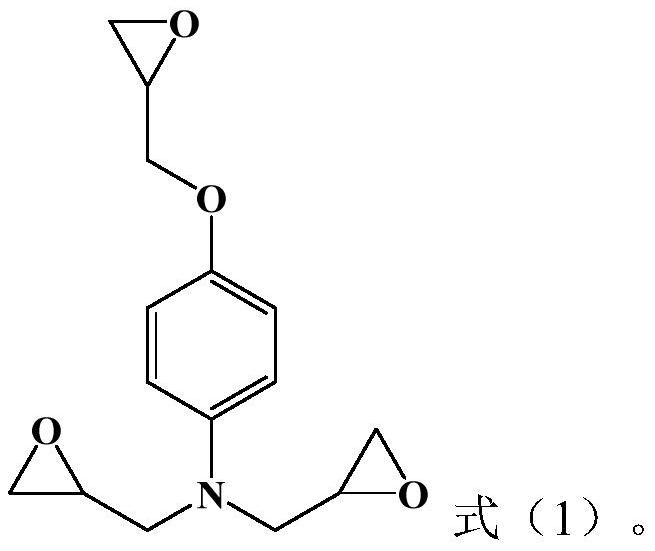

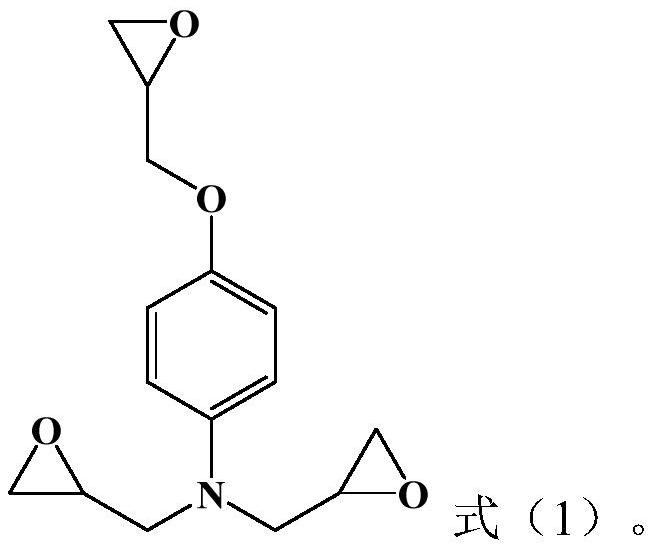

[0036] Step 1: Prepare 100g of 4-(diglycidylamino)phenyl glycidyl ether (having the structure shown in formula (1)), 4g of modified amine catalyst FXR-1020 and 1.2g of tetrakis(3-mercaptopropionic acid ) pentaerythritol esters;

[0037] Step 2: Add modified amine catalyst FXR-1020 to the 4-(diglycidylamino)phenyl glycidyl ether prepared in step 1, and disperse evenly through three-roll grinding to obtain an epoxy resin compound;

[0038] Step 3: Add pentaerythritol tetrakis(3-mercaptopropionate) into the epoxy resin compound obtained in Step 2, and disperse evenly at a speed of 2000 rpm to obtain the underfill material.

Embodiment 2

[0039] Embodiment 2 (equivalent ratio 0.12)

[0040] Step 1: Prepare 100g of 4-(diglycidylamino)phenyl glycidyl ether (with the structure shown in formula (1)), 4g of modified amine catalyst FXR-1020 and 15g of tetrakis(3-mercaptopropionic acid) Pentaerythritol esters;

[0041] Step 2: Add modified amine catalyst FXR-1020 to the 4-(diglycidylamino)phenyl glycidyl ether prepared in step 1, and disperse evenly through three-roll grinding to obtain an epoxy resin compound;

[0042] Step 3: Add pentaerythritol tetrakis(3-mercaptopropionate) into the epoxy resin compound obtained in Step 2, and disperse evenly at a speed of 2000 rpm to obtain the underfill material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com