Laser-powered GIL breakdown fault positioning system and method

A technology of laser power supply and fault location, which is applied in the direction of fault location, information technology support system, and dielectric strength test. Avoid electromagnetic interference, strong environmental adaptability, and convenient routing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

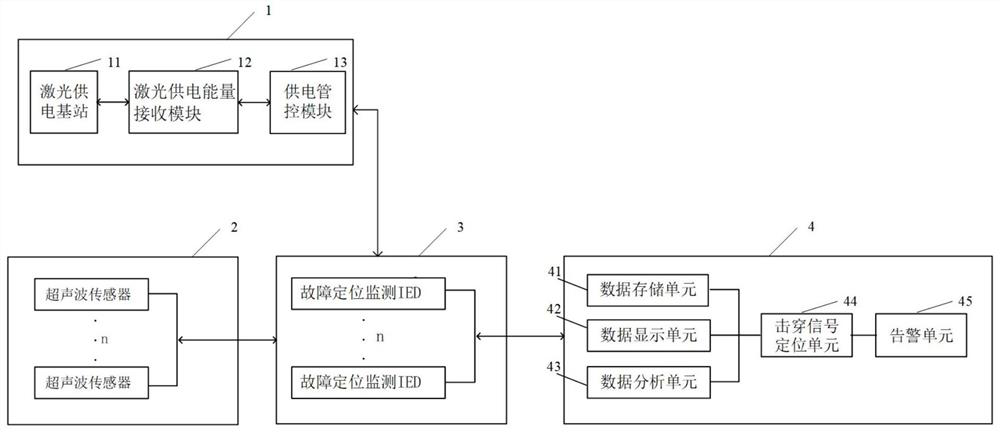

[0021] Such as figure 1 and 2 The shown laser-powered GIL breakdown fault location system includes a laser energy supply unit 1, an ultrasonic sensor array 2, a fault location monitoring IED array 3 and a background monitoring unit 4;

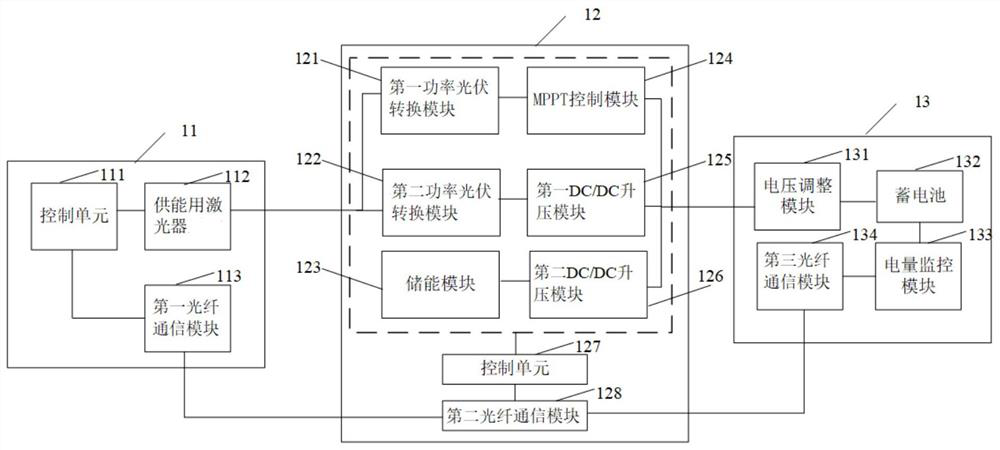

[0022] The laser power supply unit 1 includes a laser power supply base station 11, a laser power supply energy receiving module 12 and a power supply control module 13, the laser power supply base station 11 is located in the station control room on the low voltage side, and the laser power supply energy receiving unit 12 is placed in a high potential ultrasonic sensor end (on the high-voltage side equipment support), the laser power supply base station 11 is used to convert the electric energy on the low-voltage side of the power grid into laser energy transmitted by optical fiber, and transmit the laser energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com