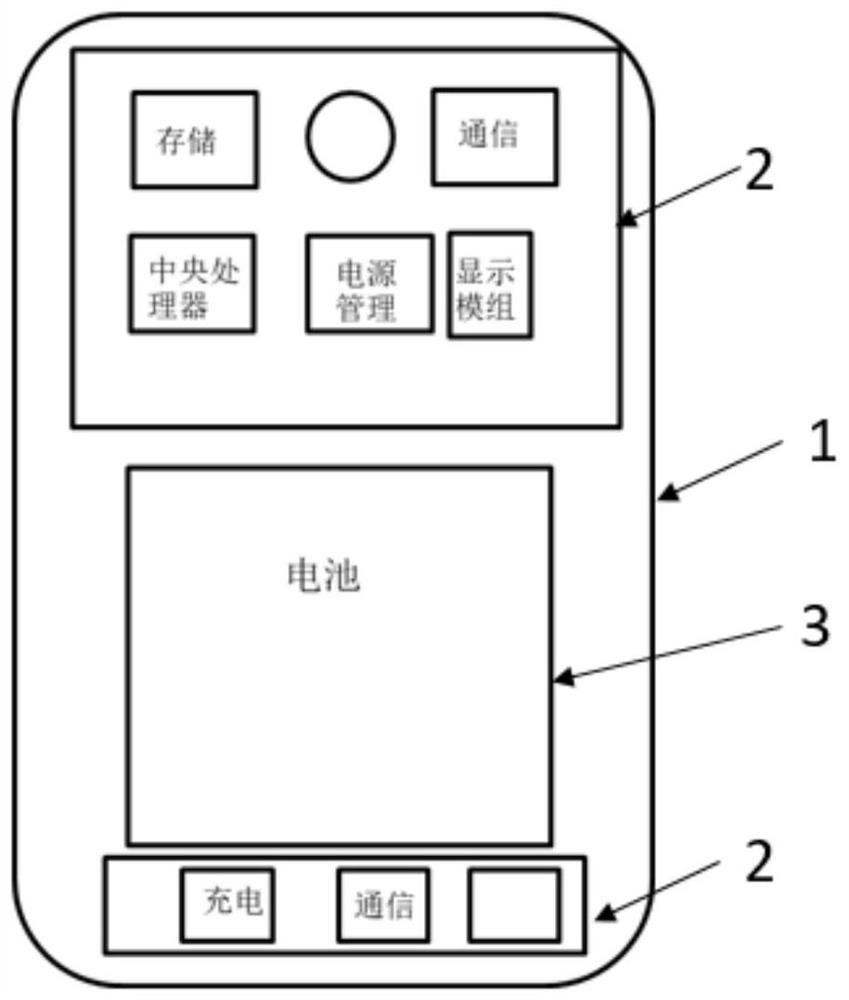

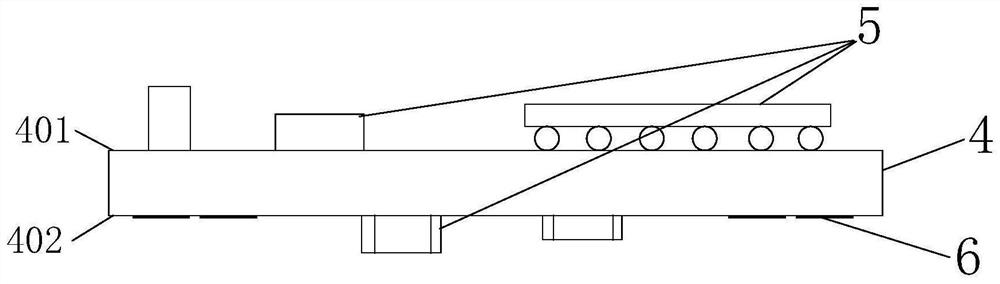

System-in-package structure, manufacturing method thereof and electronic equipment

A system-level packaging and manufacturing method technology, applied in the field of system-level packaging structure, manufacturing method and electronic equipment, can solve the problems of high cost, low efficiency, complex process, etc., achieve high aspect ratio, low cost, and ease of interface layered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

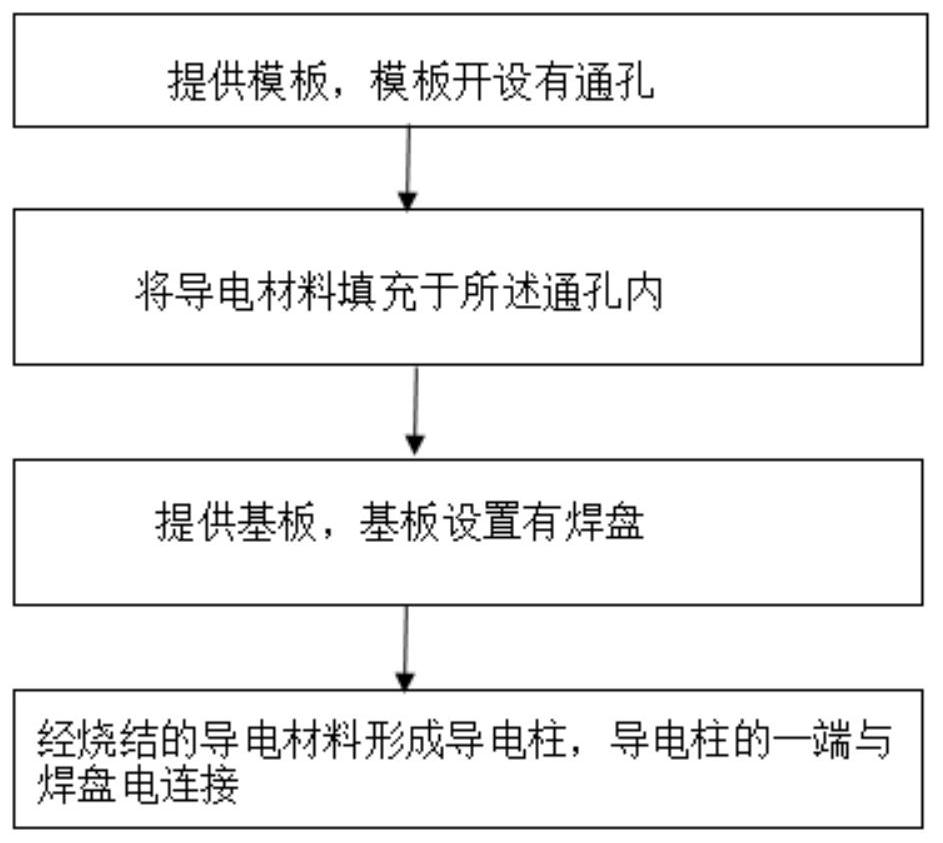

[0155] Figure 9 shows a schematic flow chart of the manufacturing method of the system-in-package structure provided by Embodiment 1, as Figure 9 shown.

[0156] S100. Template making: use silicone resin materials to make a template that can withstand high temperatures of 250°C and can be reused. The template is provided with an array of through holes corresponding to the array of pads on the back of the double-sided SiP substrate. The array of through holes can be up and down. The through-hole arrays are respectively arranged in two rows, and the left and right sides are respectively arranged in a form of a column. The thickness of the prepared template can be 0.15 mm or 0.3 mm, the diameter of the through holes on the template can be 0.2 mm, and the distance between two adjacent through holes can be 0.4 mm.

[0157] S200. Filling: pre-fix the prepared template on the transfer carrier, and then fill the SAC305 solder paste or nano-copper paste into the through-hole array ...

Embodiment 2

[0173] Figure 13 shows a schematic flow chart of the manufacturing method of the system-in-package structure provided by Embodiment 2, as Figure 13 shown.

[0174] S100. Template making: use silicone resin materials to make a template that can withstand high temperatures of 250°C and can be reused. The template is provided with an array of through holes corresponding to the array of pads on the back of the double-sided SiP substrate. The array of through holes can be up and down. The through-hole arrays are respectively arranged in two rows, and the left and right sides are respectively arranged in a form of a column. The thickness of the prepared template can be 0.4 mm or 0.5 mm, the diameter of the through holes on the template can be 0.3 mm, and the distance between two adjacent through holes can be 0.2 mm.

[0175] S200. Filling: pre-fix the prepared template on the transfer carrier, and then fill the nano-silver paste or nano-copper paste into the through-hole array o...

Embodiment 3

[0183] Figure 14 shows a schematic flow chart of the manufacturing method of the system-in-package structure provided by embodiment 3, as Figure 14 shown.

[0184] S100. Template production: Use stainless steel and other materials to make a template that can withstand high temperatures of 250°C and can be reused. The template is provided with a through-hole array corresponding to the pad array on the back of the double-sided SiP substrate. The through-hole array can be up and down. The through-hole arrays are respectively arranged in two rows or three rows, and the left and right rows are arranged in one column or two columns respectively. The thickness of the prepared template can be 0.6mm, the diameter of the through holes on the template can be 0.4mm, and the distance between two adjacent through holes can be 0.15mm.

[0185] S200. Filling: pre-fix the prepared template on the transfer carrier, and then fill the solder paste or nano-silver paste or nano-copper paste int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com