Composite solid electrolyte, preparation method thereof and solid-state battery

A solid-state electrolyte and electrolyte technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrolytes, etc., can solve the problems of low ionic conductivity and poor electrode bonding performance, and achieve uniform ion distribution and diffusion, good stability, and improved transmission. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] A second aspect of the embodiment of the present invention provides a method for preparing a composite solid electrolyte, comprising the following steps:

[0071] S10. Obtaining an inorganic electrolyte skeleton, the inorganic electrolyte skeleton includes two opposite surfaces, and at least one surface of the inorganic electrolyte skeleton is provided with a plurality of holes;

[0072] S20. Filling the pores with a polymer electrolyte, and at least forming a polymer coating layer on the surface of the inorganic electrolyte skeleton with pores to obtain the composite solid electrolyte.

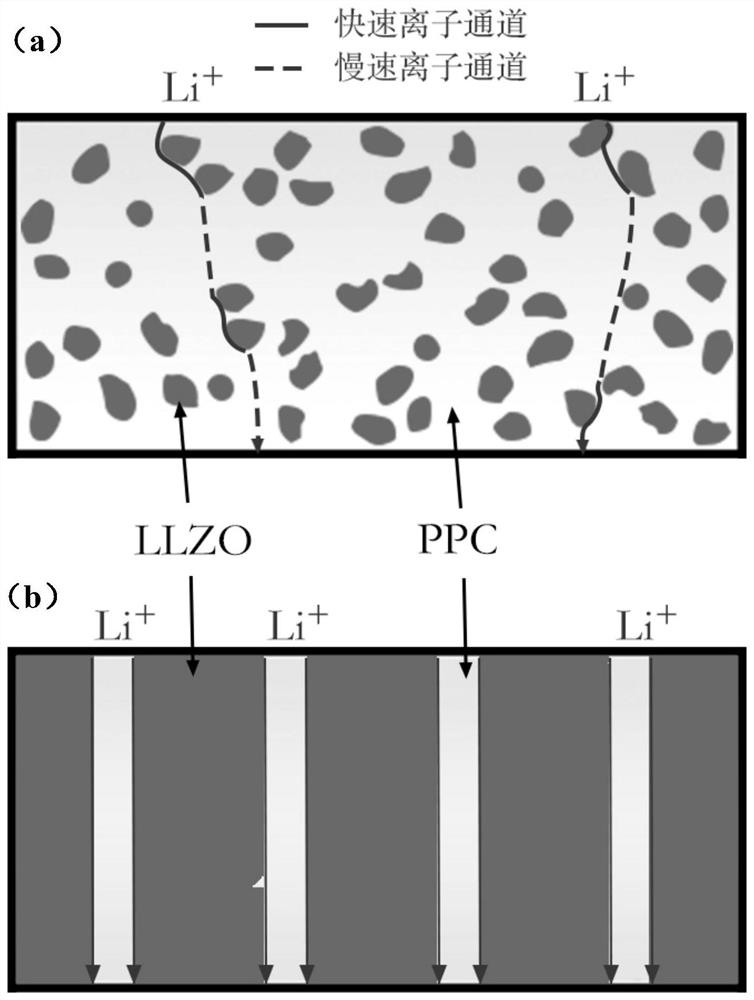

[0073] In the preparation method of the composite solid electrolyte provided by the second aspect of the present invention, an inorganic electrolyte skeleton containing several pores is used as a base material, a polymer electrolyte is filled in the pores, and a polymer electrolyte is formed at least on the surface of the inorganic electrolyte skeleton with pores. The polymer coating l...

Embodiment 1

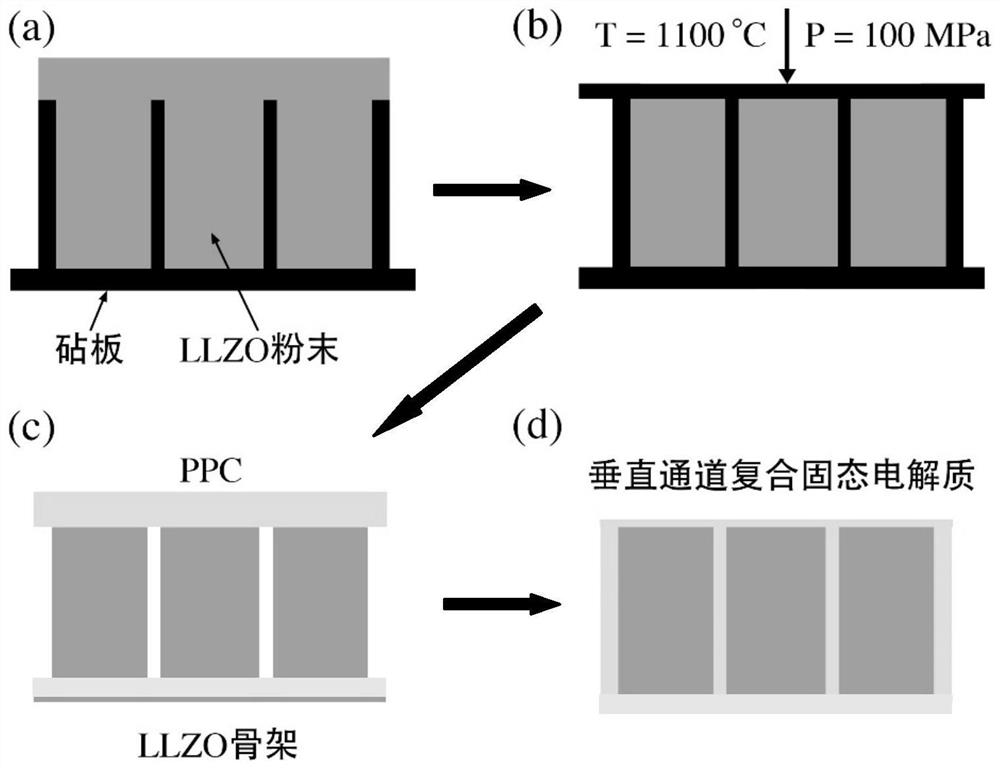

[0092] A composite solid-state electrolyte, showing attached image 3 As shown in the schematic diagram, including the following preparation methods:

[0093] ①Preparation of inorganic electrolyte skeleton: Select a chopping board with closely packed hexagonal matrix pins, the pin diameter is 50 μm, the spacing is 200 μm, and the pin length is 100 μm, fill the LLZO powder into the cutting board and tap it, then apply 100 MPa pressure at 1100 ° C, and cool it. Then, it is separated from the cutting board to obtain an inorganic electrolyte skeleton with a volume fraction of 5% through holes;

[0094] ②Filled polymer: A PPC film is stacked on the surface of the ceramic skeleton, and then hot-pressed at 45 °C with a pressure of 50 MPa, so that the PPC is heated and melted into the through holes of the LLZO skeleton, and a polymer layer with a thickness of 8 μm is formed on the surface; A composite solid electrolyte is obtained.

Embodiment 2

[0096] A composite solid-state electrolyte, comprising the following preparation methods:

[0097] ①Preparation of inorganic electrolyte skeleton: Select a chopping block with closely packed hexagonal matrix pins, the pin diameter is 50 μm, the spacing is 150 μm, and the pin length is 100 μm, fill the LLZO powder into the cutting board and tap it, then apply 110 MPa pressure at 1000 ° C, and cool it. Then, it is separated from the cutting board to obtain an inorganic electrolyte framework with a volume fraction of 10% through holes;

[0098] ②Filled polymer: A PPC film is stacked on the surface of the ceramic skeleton, and then hot-pressed at 45 °C with a pressure of 50 MPa, so that the PPC is heated and melted into the through holes of the LLZO skeleton, and a polymer layer with a thickness of 8 μm is formed on the surface; A composite solid electrolyte is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com