Exhaust gas recirculation regeneration method and device and vehicle

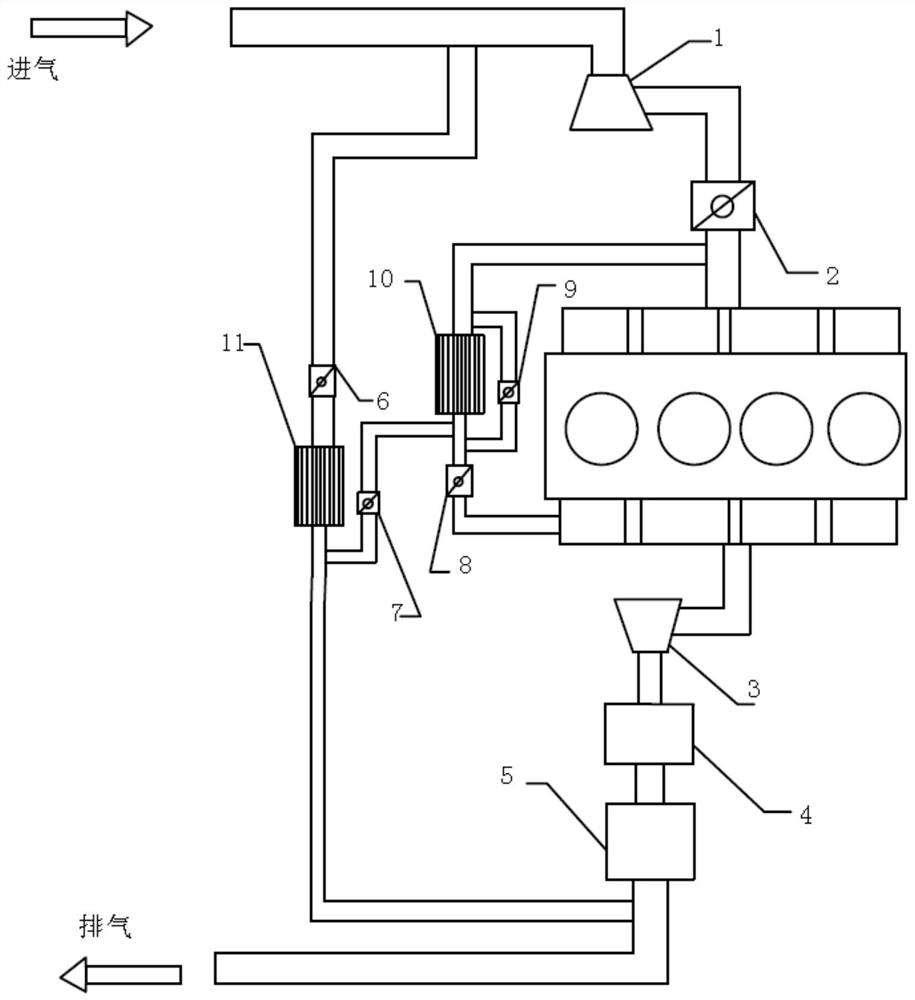

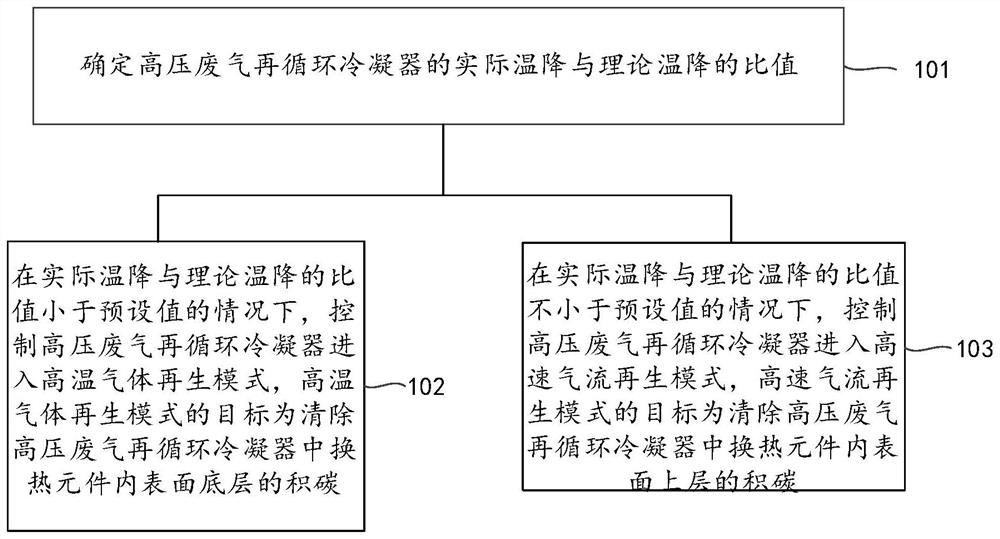

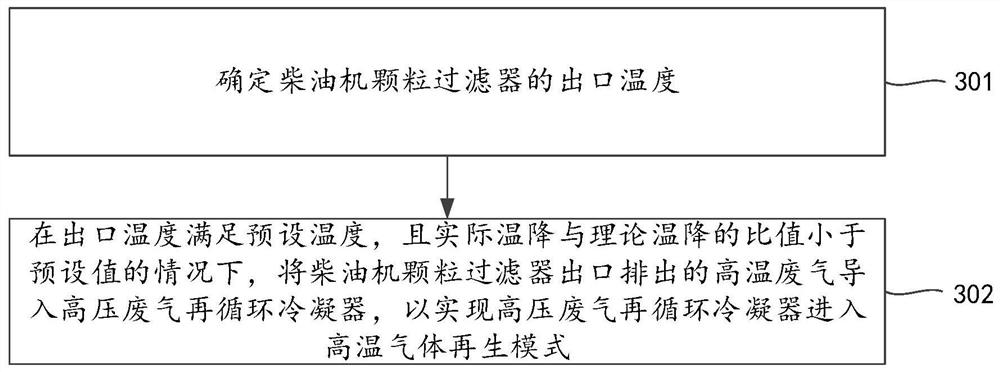

A technology for exhaust gas recirculation and vehicles, which is applied in exhaust gas recirculation, charging systems, machines/engines, etc. It can solve the problems of high-pressure EGR cooler performance attenuation and carbon deposition problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0068] The inventors have found that the current measures to solve carbon deposits in the EGR cooler are mainly divided into three aspects: 1. temperature control: increase the EGR outlet temperature; 2. improve the combustion process of the engine to reduce the emission of soot and HC; 3. improve the structure of the EGR condenser.

[0069] The inventor further studies and finds that the above-mentioned method has the following problems:

[0070] 1) Raising the EGR outlet temperature can avoid the formation of colloidal carbon deposits in the EGR condenser, but it cannot be avoided for dry powder carbon deposits. At the same time, the EGR outlet temperature is too high, which is not good for the reduction of NOx;

[0071] 2) Improve the combustion process of the engine to reduce the emission of soot and HC,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com