Alkali-activated slag-based grouting material for semi-flexible pavement as well as preparation method and application thereof

A semi-flexible pavement and grouting material technology, applied in the field of pavement materials, to achieve the effects of controllable setting time, reduction of cement usage, and reduction of CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Based on the same inventive concept, the embodiment of the present application also provides a method for preparing the above-mentioned alkali-activated slag-based grouting material for semi-flexible pavement, including the following steps:

[0048] After mixing slag, water glass, fine river sand powder, water retaining agent and coarse river sand, add water and stir to obtain the semi-flexible pavement alkali-activated slag-based grouting material.

[0049] In some embodiments, the slag, water glass, fine river sand powder, water retaining agent, and coarse river sand are mixed and stirred at a rate of less than 100r / min, and the stirring is continued at 1000-1500r / min after adding water to obtain a semi-flexible pavement. Alkali-activated slag-based grouting material.

[0050] Specifically, in some embodiments, after mixing slag, water glass, fine river sand powder, water retaining agent, and coarse river sand at a rate of 10-90r / min and stirring evenly, add 2 / 3 of th...

Embodiment 1

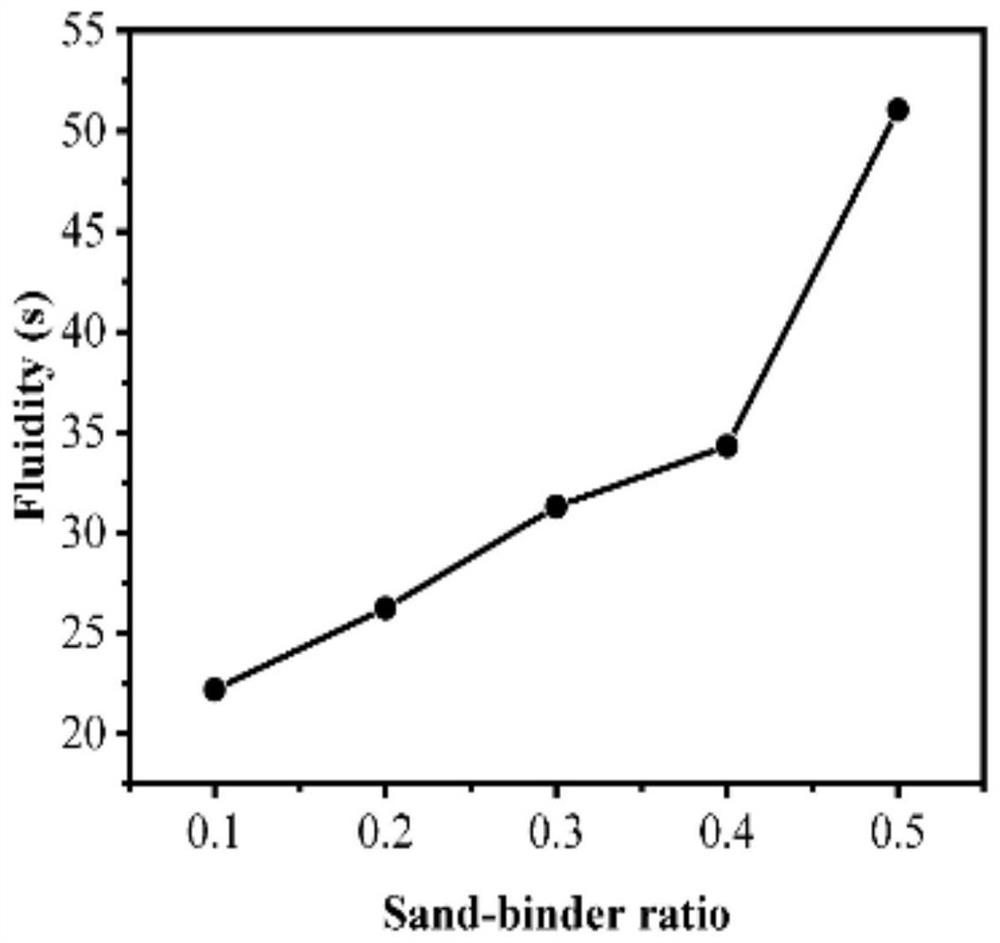

[0055] The embodiment of the present application provides an alkali-activated slag-based grouting material for semi-flexible pavement, including the following raw materials in parts by weight: 75 parts of slag, 15 parts of water glass, 10 parts of fine river sand powder, 0.2 parts of water retaining agent, 40 parts of coarse river sand, 36 parts of water;

[0056] Among them, the slag is made of water-quenched granulated blast furnace slag and ball milled to a particle size of 2-200 μm; the modulus of water glass is 2; the particle size of fine river sand powder is 2-300 μm; the sieve of coarse river sand 0.6mm The pore passing rate is 100%, and the sieve passing rate of 0.075mm is ≤0.2%; the water retaining agent is sodium carboxymethyl starch.

[0057] The preparation method of the alkali-activated slag-based grouting material for the semi-flexible pavement comprises the following steps:

[0058] Mix slag, water glass, fine river sand powder, water retaining agent and coars...

Embodiment 2

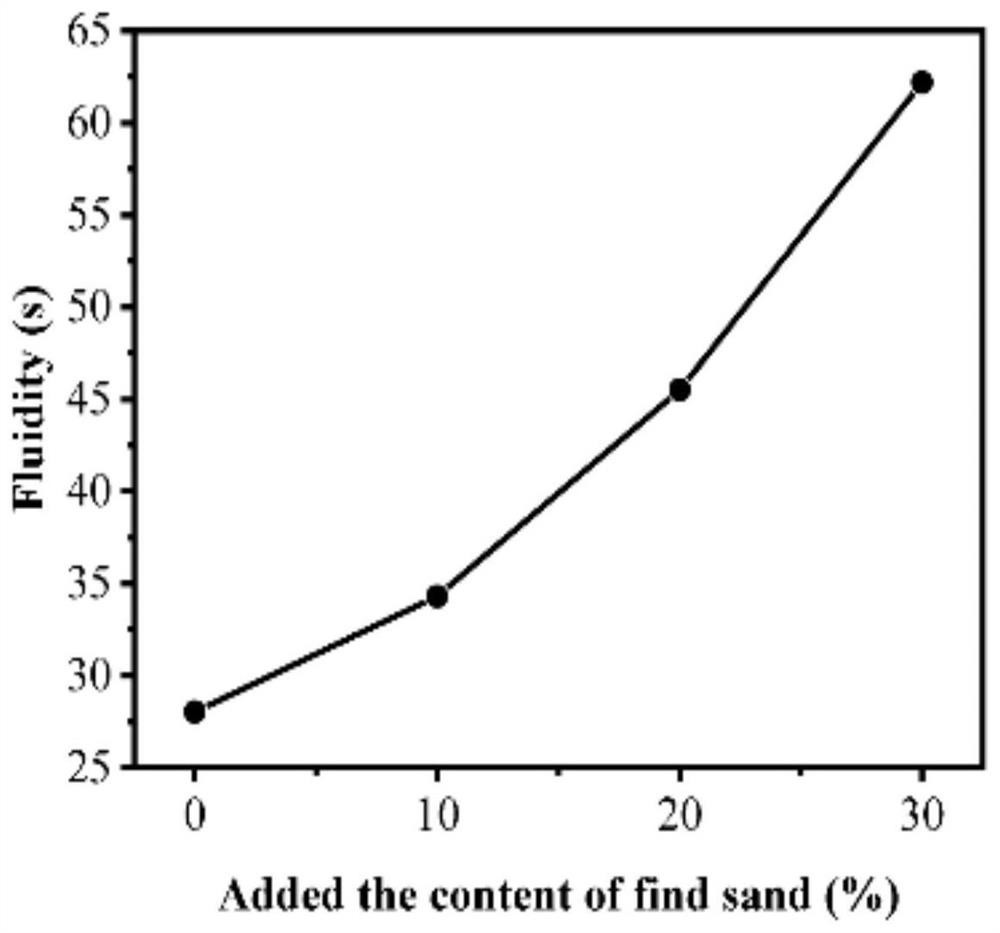

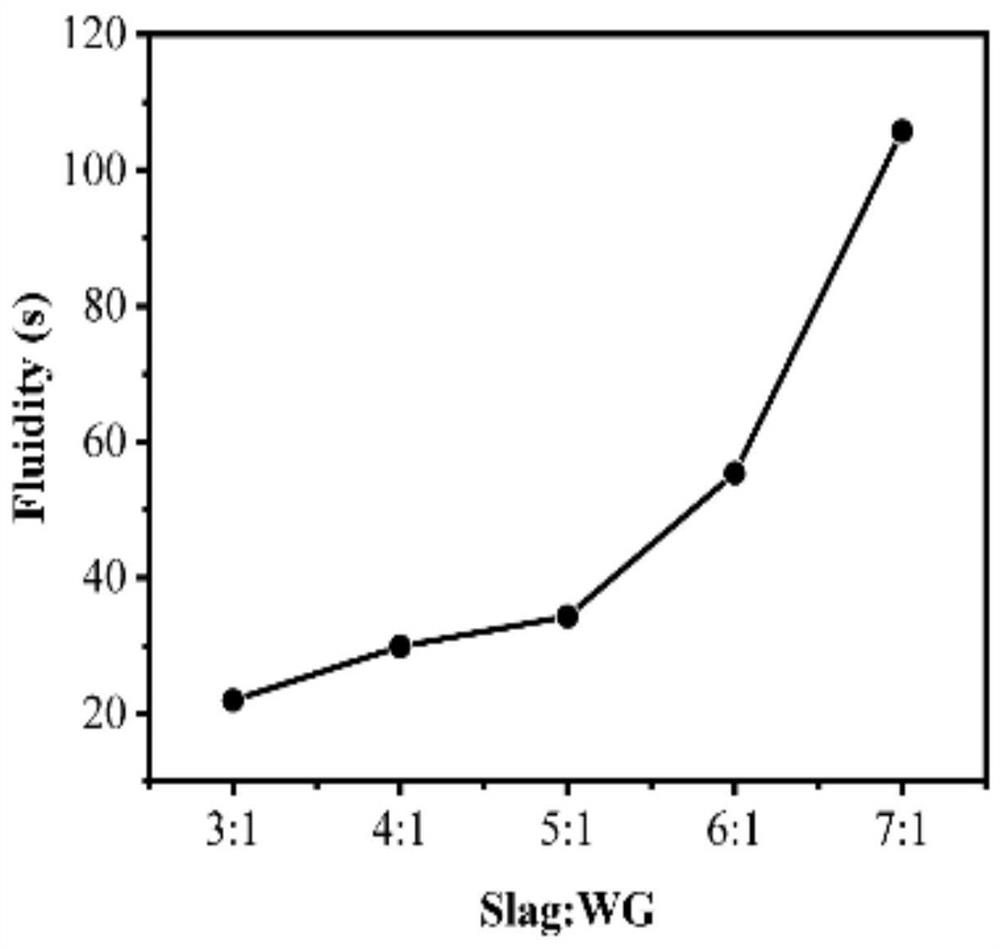

[0065] The embodiment of the present application provides an alkali-activated slag-based grouting material for semi-flexible pavements, including the following raw materials in parts by weight: slag, water glass, 20 parts of fine river sand powder, 0.2 parts of water-retaining agent, and 40 parts of coarse river sand , 36 parts of water, the sum of the parts by weight of slag and water glass is 80 parts, and the weight ratio of slag and water glass is 5:1;

[0066] Among them, the slag is made of water-quenched granulated blast furnace slag and ball milled to a particle size of 2-200 μm; the modulus of water glass is 2; the particle size of fine river sand powder is 2-300 μm; the sieve of coarse river sand 0.6mm The pore passing rate is 100%, and the sieve passing rate of 0.075mm is ≤0.2%; the water retaining agent is sodium carboxymethyl starch.

[0067] The preparation method of the alkali-activated slag-based grouting material for semi-flexible pavement is the same as in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com