Low-density flame-retardant polypropylene foam material and preparation method thereof

A technology of flame-retardant polypropylene and foaming materials, applied in the field of low-density flame-retardant polypropylene foaming materials and their preparation, can solve the problems of unbalanced foaming effect and flame-retardant performance, and achieve environmental protection and pollution-free foaming costs. , low VOC content, uniform apparent quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

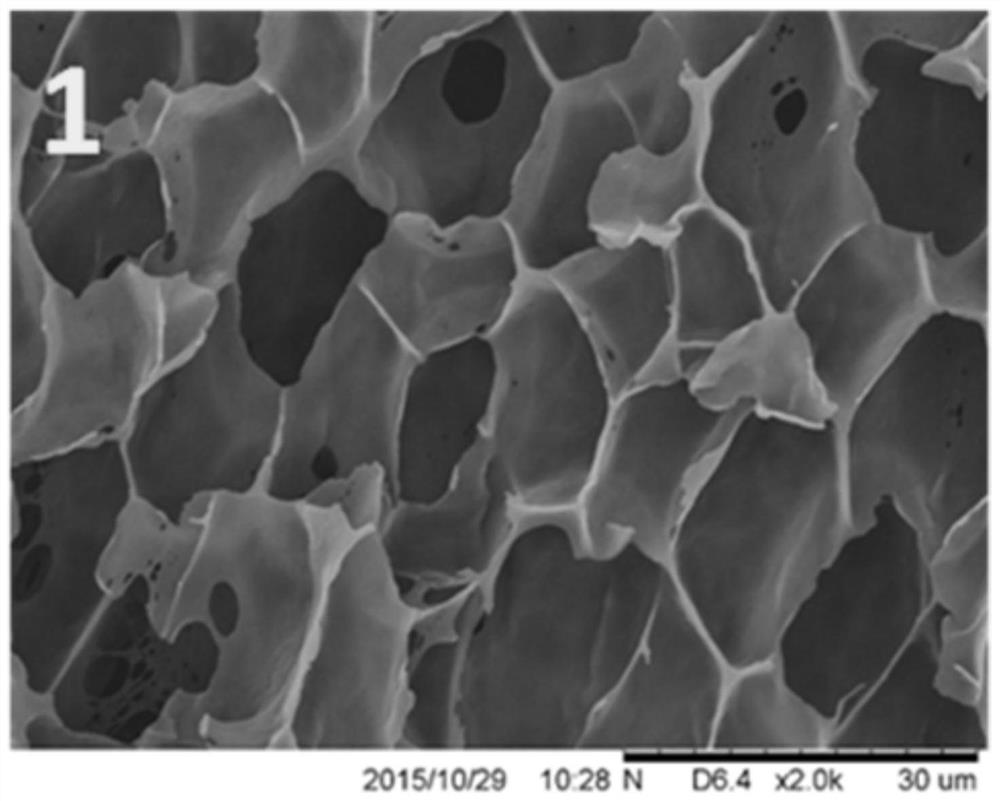

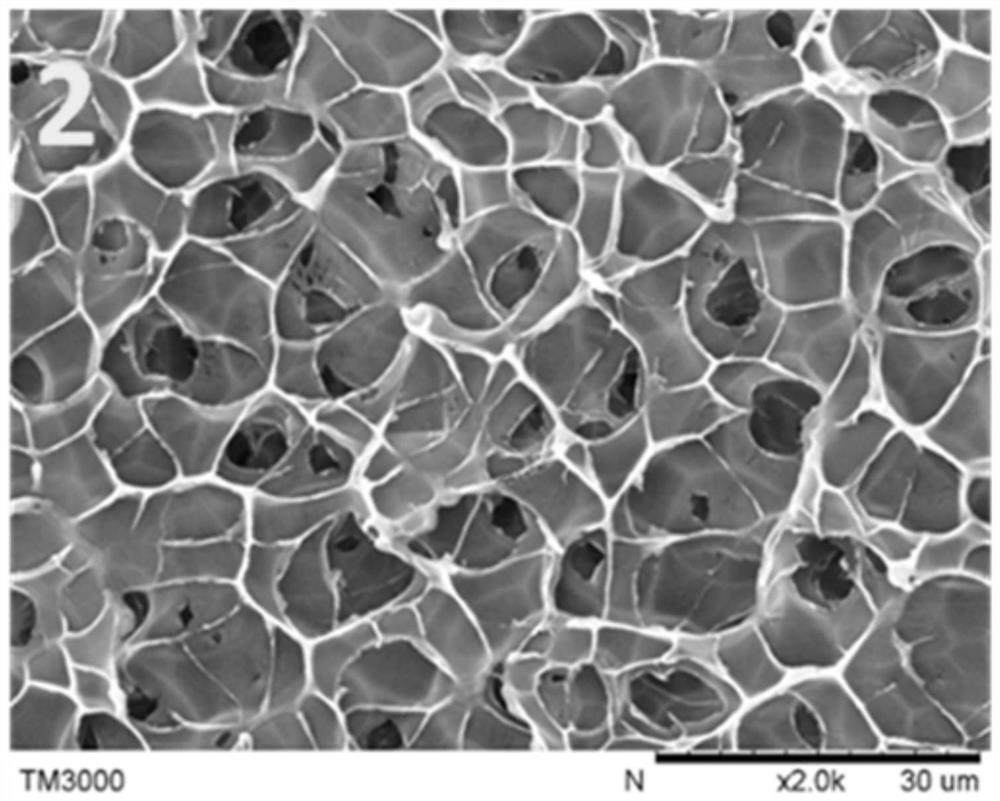

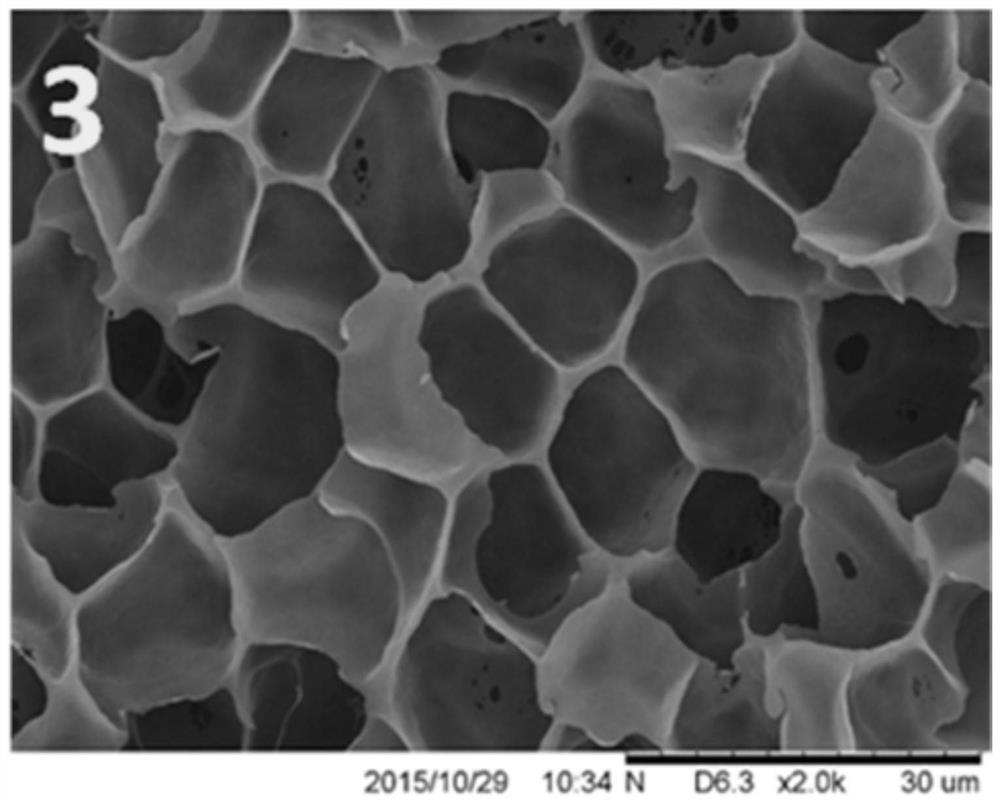

Image

Examples

Embodiment 1

[0044] A preparation method of a low-density flame-retardant polypropylene foam material, comprising the following steps:

[0045] (1) Take the following components by weight: 73 parts of polypropylene, 20 parts of flame retardant, 3 parts of iron oxide, 3 parts of tribasic sulfate, 0.3 part of polyethylene wax, 0.3 part of stearic acid, toughening 6 parts of antioxidant, 0.2 parts of antioxidant 1010 and antioxidant 168, the above components were blended in a low-speed mixer for 20 minutes, added to the twin-screw extruder, and the temperature of the extruder 1 to 12 was set to 150°C, 180°C, 200°C, 200°C, 200°C, 200°C, 205°C, 205°C, 205°C, 205°C, 210°C, 210°C, the head is 200°C, the mixed material is melted, plasticized and kneaded Mixing, extruding, cooling, pelletizing, and drying to obtain a flame-retardant polypropylene material.

[0046] (2) Put the flame-retardant polypropylene material into the autoclave, and use supercritical fluid technology for foaming. The specifi...

Embodiment 2

[0047] In Example 2 and Example 3, under the premise that the foaming process parameters remain unchanged, the product formula for preparing flame-retardant polypropylene materials is adjusted, and low-density flame-retardant polypropylene foam materials are prepared respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com