Anti-fog and anti-frost film and preparation method thereof

An anti-frost and anti-fog technology, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems that the anti-fog and anti-frost coatings need to be further improved for a long time, and achieve good anti-fog effects and good Anti-frost effect, effect of enhancing abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

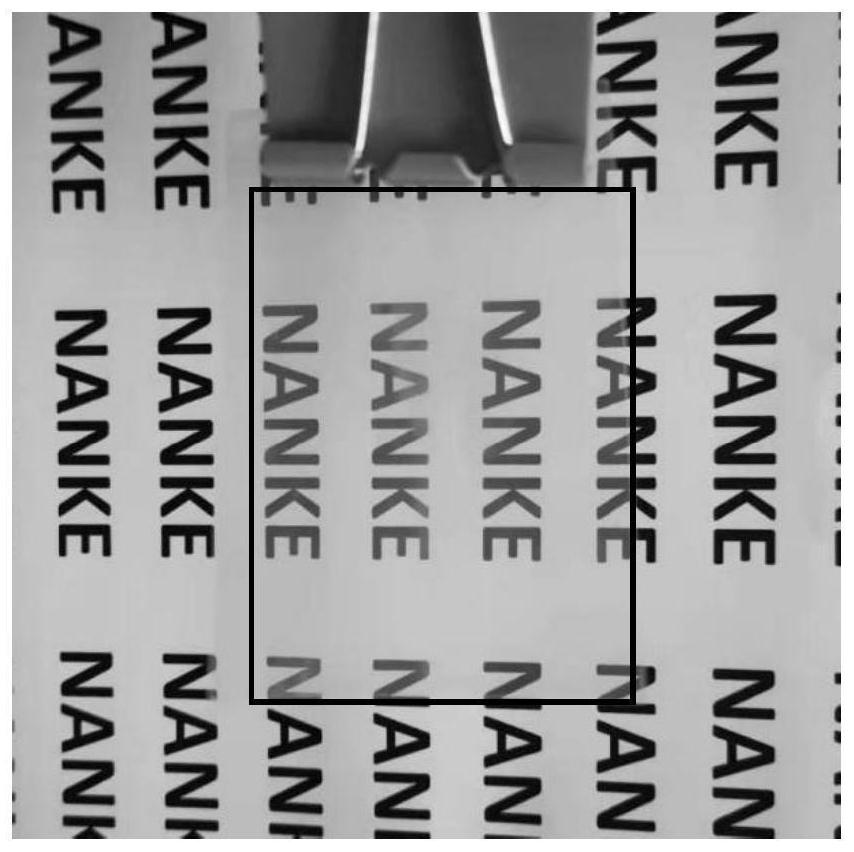

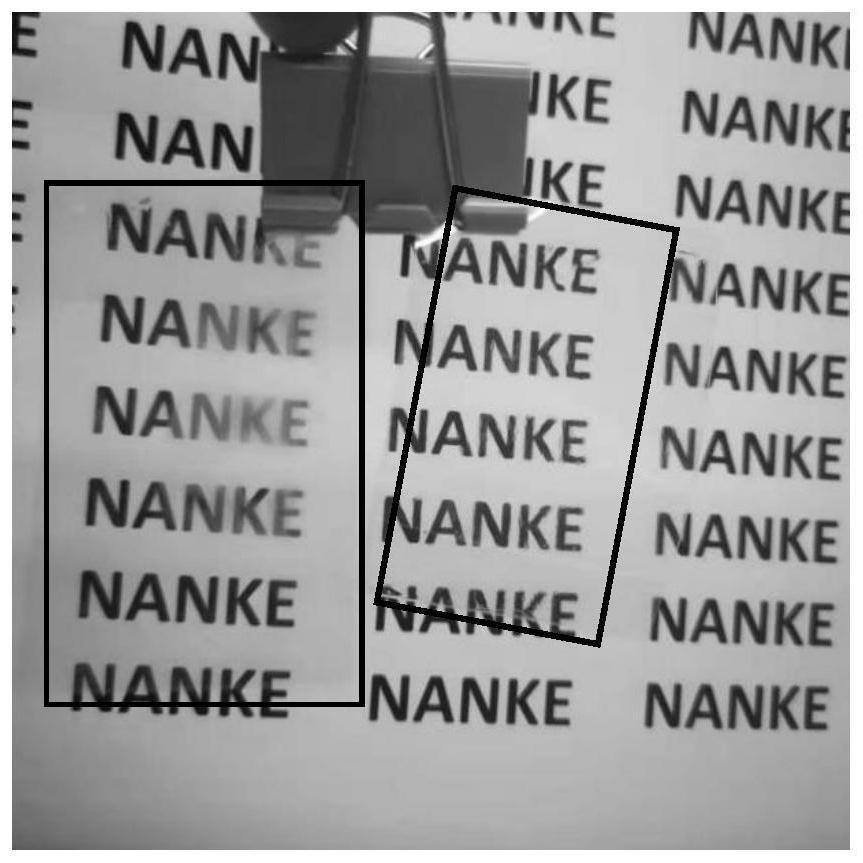

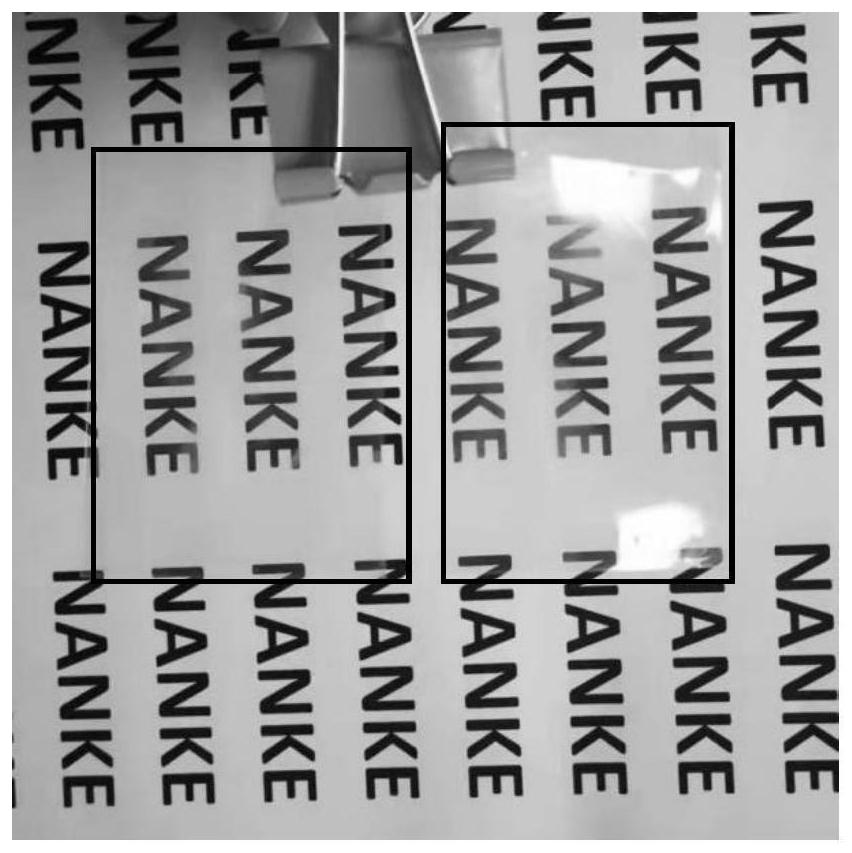

Image

Examples

Embodiment 1

[0089] In the present embodiment, a kind of anti-fog and anti-frost film is provided, and described anti-fog and anti-frost film comprises bottom UV curing anti-fog layer and top floor water-based anti-fog and anti-frost layer, and the preparation raw material of described bottom UV curing anti-fog layer is by weight Serving count, including the following components:

[0090]

[0091]

[0092] The preparation raw material of described top layer water-based anti-fog anti-frost layer comprises following components in parts by weight:

[0093] 80 parts of water-based polyurethane;

[0094] 12 parts of surfactant;

[0095] 8 parts of materials that can lower the freezing point of water.

[0096] Among them, the UV resin oligomer is non-ionic one-component waterborne polyurethane; the acrylic monomer is acrylic acid; the surfactant containing acrylic acid group is polyether containing acrylic acid group; the photoinitiator is photoinitiator 1173; The auxiliary agent is a d...

Embodiment 2

[0102] In the present embodiment, a kind of anti-fog and anti-frost film is provided, and described anti-fog and anti-frost film comprises bottom UV curing anti-fog layer and top floor water-based anti-fog and anti-frost layer, and the preparation raw material of described bottom UV curing anti-fog layer is by weight Serving count, including the following components:

[0103]

[0104]

[0105] The preparation raw material of described top layer water-based anti-fog anti-frost layer comprises following components in parts by weight:

[0106] 70 parts of water-based polyurethane;

[0107] 25 parts of surfactant;

[0108] 5 parts of materials that can lower the freezing point of water.

[0109] Among them, the UV resin oligomer is cationic one-component waterborne polyurethane; the acrylic monomer is methyl methacrylate; the surfactant containing acrylic group is polyester containing acrylic group; the photoinitiator is photoinitiator 184; other additives are leveling agen...

Embodiment 3

[0115] In the present embodiment, a kind of anti-fog and anti-frost film is provided, and described anti-fog and anti-frost film comprises bottom UV curing anti-fog layer and top floor water-based anti-fog and anti-frost layer, and the preparation raw material of described bottom UV curing anti-fog layer is by weight Serving count, including the following components:

[0116]

[0117] The preparation raw material of described top layer water-based anti-fog anti-frost layer comprises following components in parts by weight:

[0118] 90 parts of water-based polyurethane;

[0119] 5 parts of surfactant;

[0120] 5 parts of materials that can lower the freezing point of water.

[0121] Among them, the UV resin oligomer is an anionic one-component waterborne polyurethane; the acrylic monomer is ethyl acrylate; the surfactant containing acrylic acid groups is fluoroether containing acrylic acid groups; the photoinitiator is photoinitiator 1173; Other additives are defoamers; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com