Amorphous strip heat treatment take-up and pay-off system and control method

A technology for unwinding and unwinding of amorphous strips, applied in heat treatment process control, heat treatment furnaces, heat treatment equipment, etc., can solve problems such as difficult to achieve constant tension and constant speed, and achieve constant strip moving line speed and strip deformation The effect of uniform and strong technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to more fully explain the implementation of the present invention, the implementation examples of the present invention are provided, and these implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

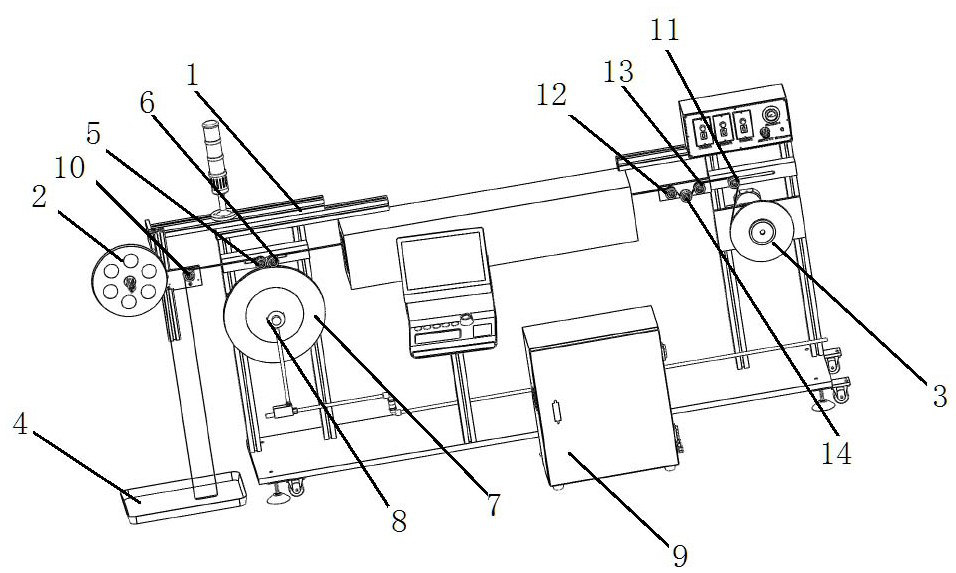

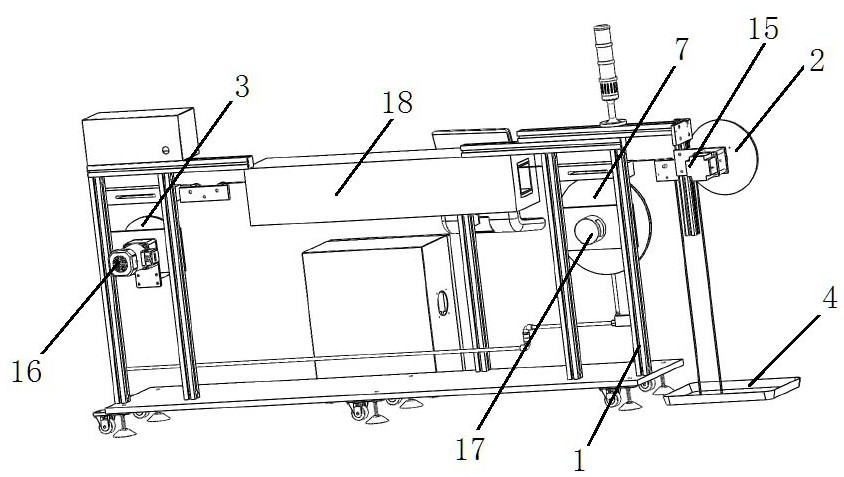

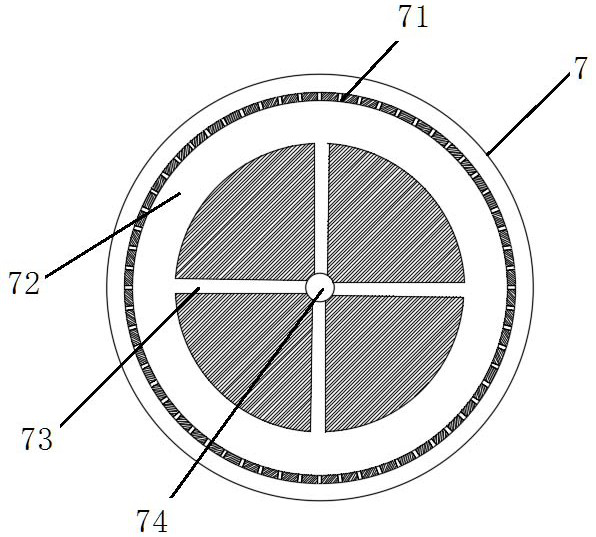

[0025] Each mark in the attached drawings is: 1: frame; 2: tape release reel; 3: tape take-up reel; 4: contact strip detection disk; 5: front roller; 6: rear roller; 7: transition disk; 71: Air hole; 72: inner cavity; 73: airway; 74: joint of rotary joint; 8: rotary joint; 9: vacuum generating device; 10: first support roller; 11: end support roller; 12: roller A; 13: Roller B; 14: Roller C; 15: stepping motor; 16: servo motor; 17: magnetic damper; 18: heat treatment furnace; 19: rotating shaft.

[0026] The constant speed and constant tension system in the heat treatment of nanocrystalline strips, including the installation on the frame 1, are all driven by motors. The tape reel 2 and the take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com