Medicinal sucrose pellet core and preparation method thereof

A technology of medicinal sucrose and sucrose cores, which is applied in the direction of pharmaceutical formulations, medical preparations of non-effective ingredients, and pill delivery, and can solve the problems of relatively large influence of adhesive brittleness, low yield of sucrose cores, and pill delivery. Low core yield and other issues, to achieve the effect of low cost, convenient operation, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

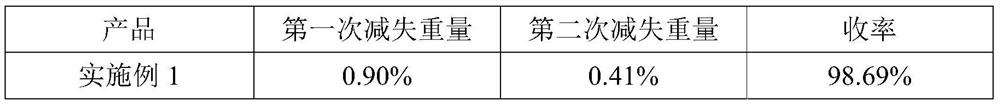

Examples

Embodiment 1

[0035] A sucrose ball core comprises the following raw materials in parts by weight: 60 parts of sucrose, 40 parts of cornstarch; 62% sucrose syrup obtained by heating and boiling a 40% sucrose solution as a binder.

[0036] The concrete preparation method of sucrose ball core is:

[0037] Step (1), premixing: at normal temperature, sucrose and cornstarch are premixed according to the proportion to obtain mixed powder;

[0038] Step (2), pulverization: at normal temperature, the above-mentioned mixed powder is pulverized twice with a platform pulverizer (the internal screen is 150 mesh) to obtain pulverized sucrose starch;

[0039] Step (3), preparation of adhesive: prepare 40% sucrose solution with sucrose and water, heat to boiling, continue to boil for 4 hours to obtain 62% sucrose syrup;

[0040] Step (4), mother nucleus preparation: the 10kg sucrose starch pulverization that step (2) obtains is dropped into centrifugal granulator, 50kg sucrose starch pulverization joins ...

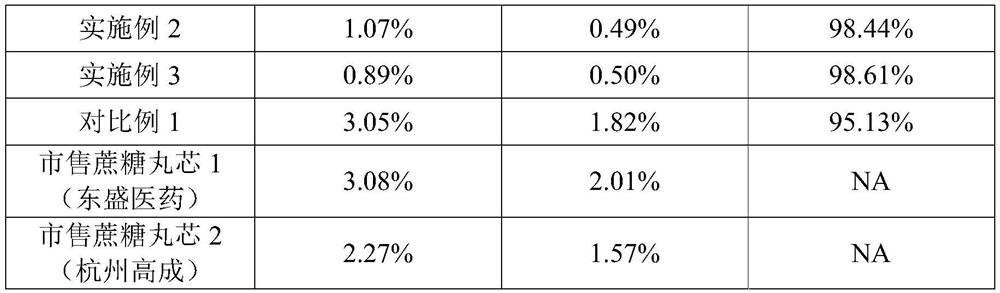

Embodiment 2

[0047] A sucrose ball core comprises the following raw materials in parts by weight: 70 parts of sucrose, 30 parts of cornstarch; 59% sucrose syrup obtained by heating and boiling 45% sucrose solution as a binder.

[0048] The concrete preparation method of sucrose ball core is:

[0049] Step (1), premixing: at normal temperature, sucrose and cornstarch are premixed according to the proportion to obtain mixed powder;

[0050] Step (2), pulverization: at normal temperature, the above-mentioned mixed powder is pulverized twice with a platform pulverizer (the internal screen is 150 mesh) to obtain pulverized sucrose starch;

[0051] Step (3), preparation of adhesive: prepare 45% sucrose solution with sucrose and water, heat to boiling, and continue to boil for 3 hours to obtain sucrose syrup with a final concentration of 59%;

[0052] Step (4), mother core preparation: the 15kg sucrose starch pulverization that step (2) obtains is dropped into centrifugal granulator, and 45kg su...

Embodiment 3

[0059] A sucrose ball core comprises the following raw materials in parts by weight: 85 parts of sucrose, 15 parts of cornstarch; 56% sucrose syrup obtained by heating and boiling a 50% sucrose solution as a binder.

[0060] The concrete preparation method of sucrose ball core is:

[0061] Step (1), premixing: at normal temperature, sucrose and cornstarch are premixed according to the proportion to obtain mixed powder;

[0062] Step (2), pulverization: at normal temperature, the above-mentioned mixed powder is pulverized twice with a platform pulverizer (the internal screen is 150 mesh) to obtain pulverized sucrose starch;

[0063] Step (3), preparation of adhesive: prepare 50% sucrose solution with sucrose and water, heat to boiling, continue to boil for 2 hours to obtain 56% sucrose syrup;

[0064] Step (4), mother core preparation: the 5kg sucrose starch pulverization that step (2) obtains is put into centrifugal granulator, and 55kg sucrose starch pulverization joins in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com