Industrial water-containing hydrogen chloride gas dehydration device and dehydration method

A hydrogen chloride gas and dehydration device technology, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chemical instruments and methods, etc., can solve the surrounding environmental pollution, easy to produce precipitation, affect the dehydration effect of hydrogen cyanide gas, etc. Problems, to improve effect, the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

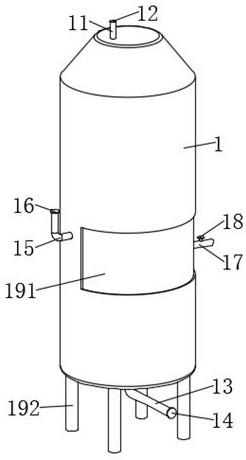

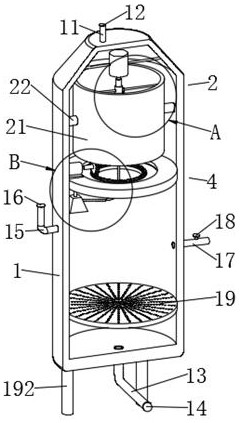

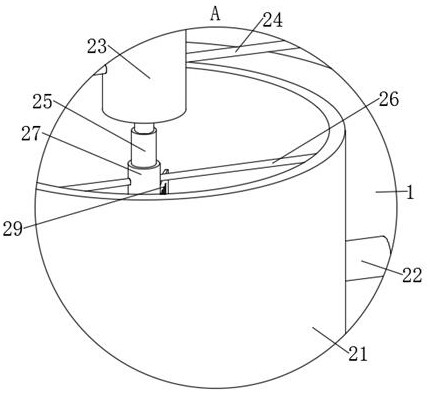

[0037] Example: such as Figure 1-8As shown, the present invention provides a kind of industrialized hydrochloric gas dehydration device, comprises dehydration tower 1, and the upper end of dehydration tower 1 is fixedly installed feed pipe 11, through feed pipe 11, can conveniently dehydrate the chemical used for hydrogen chloride gas The chemical agent is added to the inside of the dehydration tower 1, and the side of the dehydration tower 1 far away from the feed pipe 11 is fixedly installed with a discharge pipe 13, which can discharge the used chemical agents, and the outer walls of the dehydration tower 1 are respectively fixedly installed with air inlet pipes 15 and the exhaust pipe 17, through the intake pipe 15, the hydrogen chloride gas to be dehydrated can be easily introduced into the inside of the dehydration tower 1, the exhaust pipe 17 can discharge the dehydrated hydrogen chloride gas, and the inner wall of the dehydration tower 1 is fixedly installed with a fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com