Pressure-resistant composite film for lithium battery and preparation method of pressure-resistant composite film

A composite membrane and lithium battery technology, applied in battery pack parts, chemical instruments and methods, applications, etc., can solve the problems of battery bulging deformation, easy collapse, and affecting battery safety, etc., to solve the problem of flatulence, bulging deformation, and good shell flushing Performance, the effect of improving the pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of pressure-resistant composite film for lithium battery and preparation method thereof:

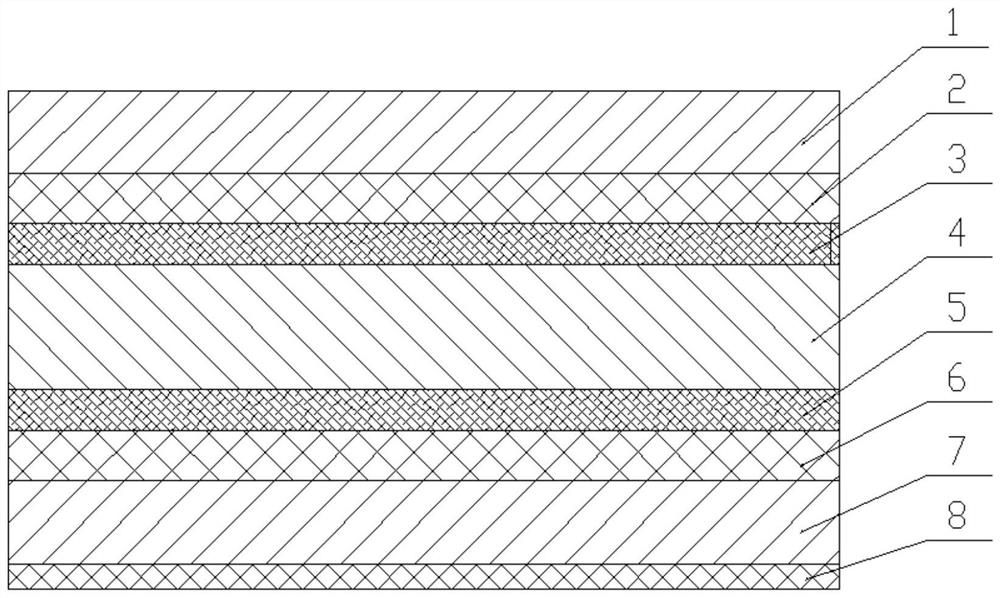

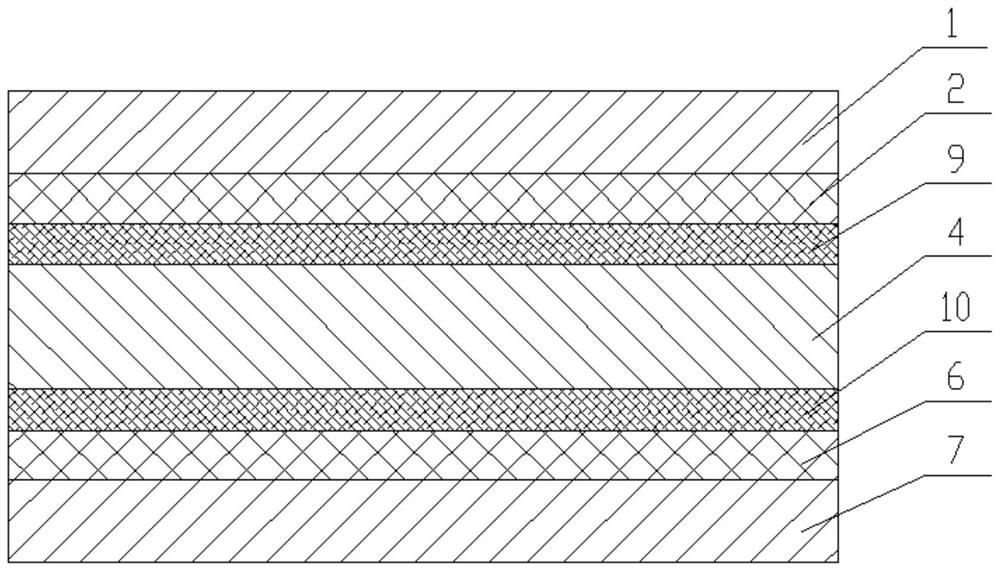

[0028] see figure 1 , a pressure-resistant composite film for a lithium battery, comprising a protective layer 1, a first adhesive layer 2, a first corrosion-resistant coating 3, a pressure-resistant layer 4, and a second corrosion-resistant coating 5 arranged in sequence from top to bottom , second adhesive layer 6, heat seal layer 7, slip agent layer 8, protective layer 1, first adhesive layer 2, first corrosion-resistant coating 3, pressure-resistant layer 4, second corrosion-resistant coating 5 , the second adhesive layer 6 and the heat-sealing layer 7 are formed into an integral composite film structure by dry lamination or high-temperature hot pressing, and the slip agent layer 8 is coated on the lower surface of the heat-sealing layer 7 .

[0029] Wherein, the thickness of the protective layer 1 is 10-60 μm, and the thickness of the protective layer 1 in this embod...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, except that the material of the pressure-resistant layer 4 is rolled copper foil.

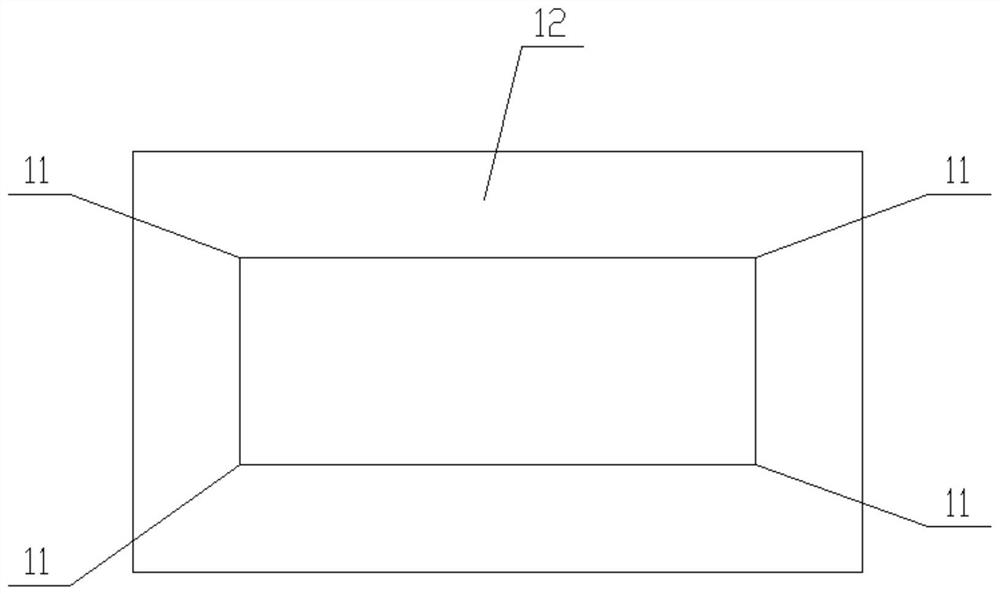

[0042] After testing, the pressure-resistant composite film for lithium batteries prepared in this embodiment has a depth of 8.2mm when the shell is damaged; image 3 with Figure 4 In the middle stretch position 11), there is a collapse phenomenon; in the case of inflation of 1.0kgf, the battery swells seriously.

Embodiment 3

[0044] This embodiment is basically the same as Embodiment 1, except that the pressure-resistant layer 4 is made of rolled stainless steel foil.

[0045] After testing, the pressure-resistant composite film for lithium batteries prepared in this example has a depth of 5.1 mm when the shell is damaged; after punching the shell 5 mm, press the top angle ( image 3 with Figure 4 In the middle stretching position 11), there is no collapse phenomenon; in the case of inflation of 1.0kgf, the battery has a slight swelling; in the case of inflation of 1.5kgf, the battery swelling is serious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com