Multifunctional automatic cable take-up equipment

A wire take-up device and multi-functional technology, which can be used in packaging/bundling items, labels, packaging, etc., and can solve problems such as being difficult to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The structure and working principle of the multifunctional cable automatic take-up device of the present invention will be further described in detail below through the embodiments and the accompanying drawings.

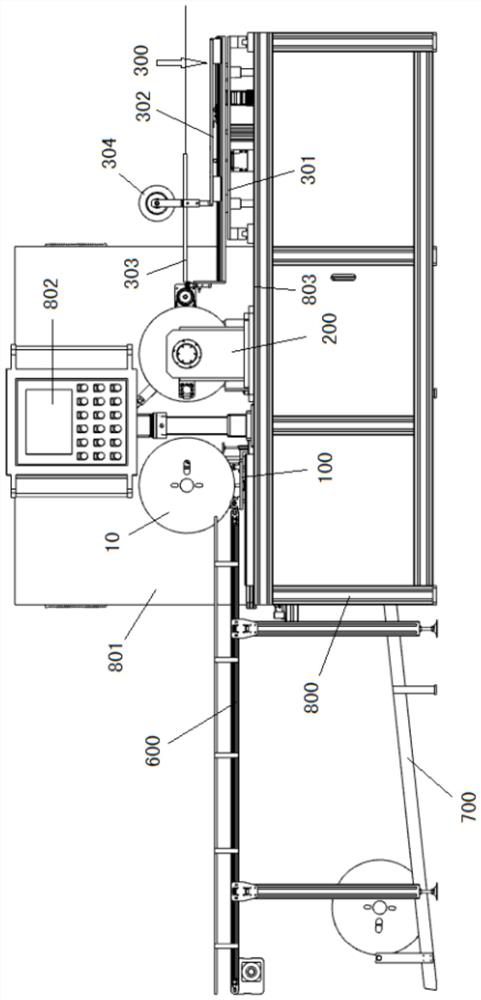

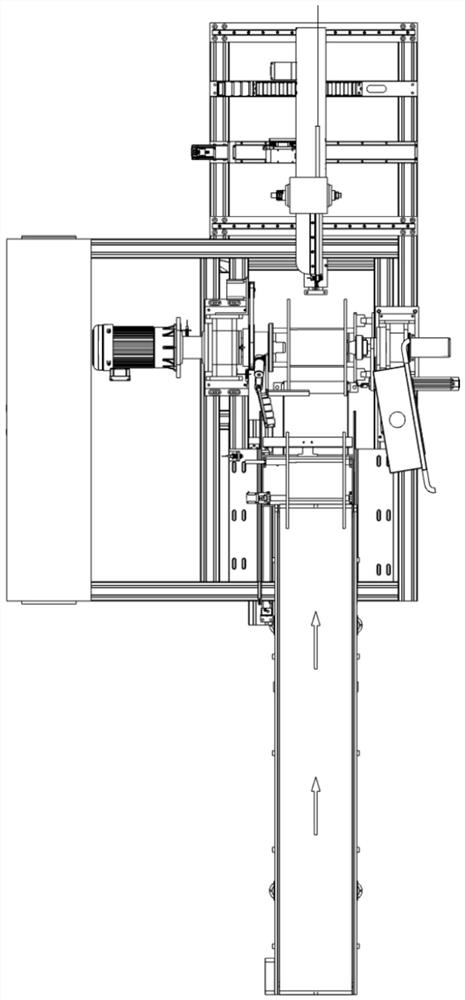

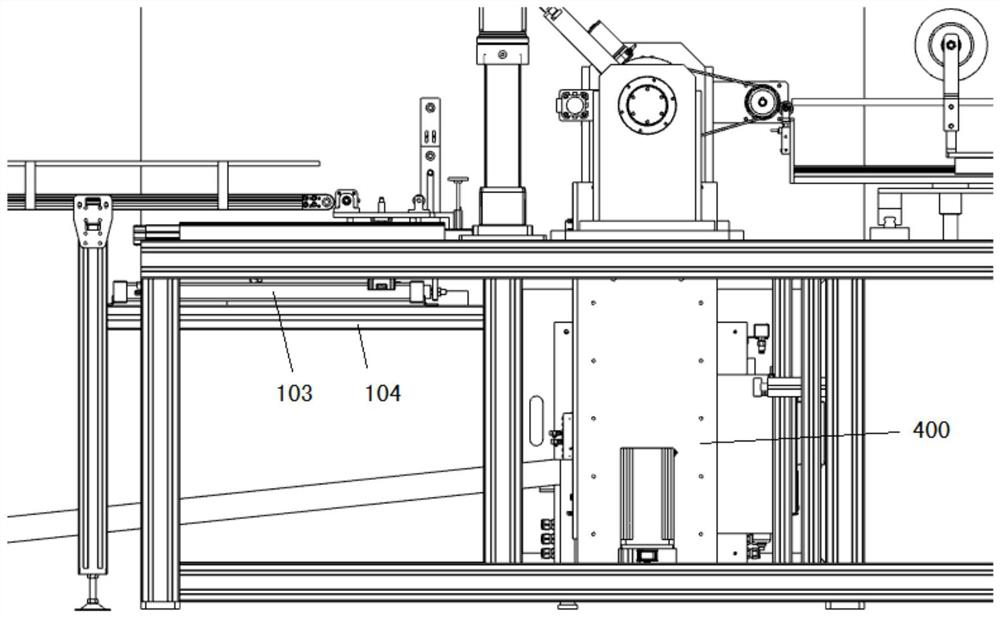

[0077] see Figure 1-4 As shown, the multifunctional cable automatic take-up device of the present invention has a main body layout as follows:

[0078] The empty reel conveying mechanism 600 loaded with several cable reels 10 is placed on one side of the equipment body 800, and its end is close to and abutted against the side of the positioning upper disk assembly 100 on the equipment body 800, and the positioning upper disk assembly 100 is received from the empty The reel conveying mechanism 600 travels the incoming cable reel 10 and positions it. The wire take-up coating assembly 200 is placed on the equipment body 800 on the other side of the positioning upper disk assembly 100 , and the positioning upper disk assembly 100 pushes the positioned cable drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com