A method for preparing collagen with triple helix structure by spray drying

A technology of collagen and collagen powder, which is applied in the field of protein preparation, can solve the problems of restricting the use in the field of biological 3D printing, and achieve the effects of good resolubility, reduced energy consumption, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

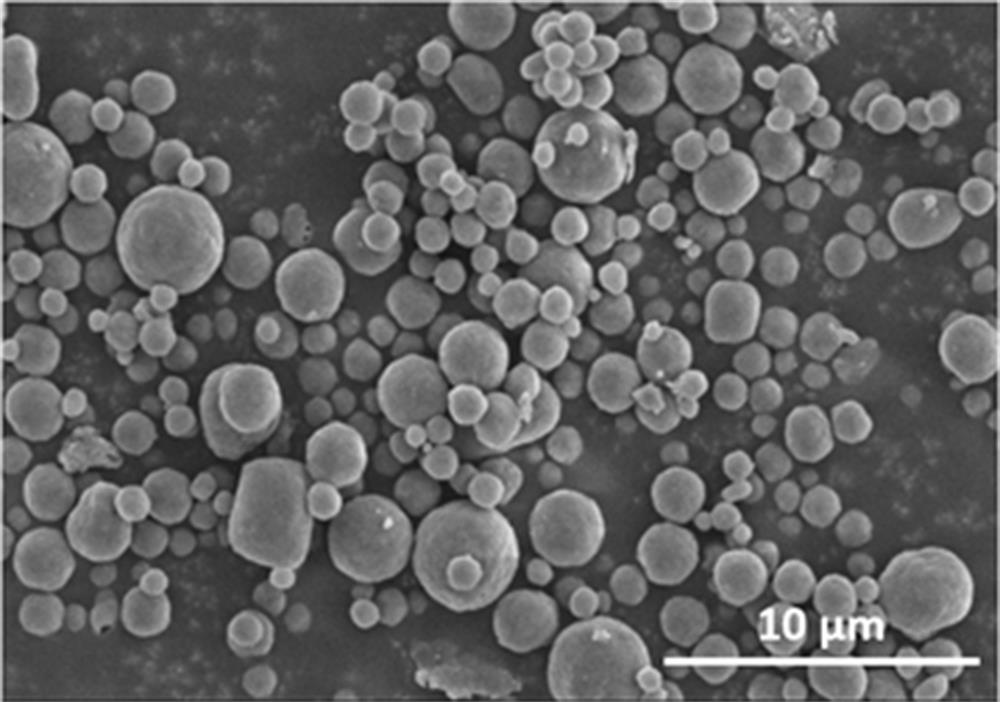

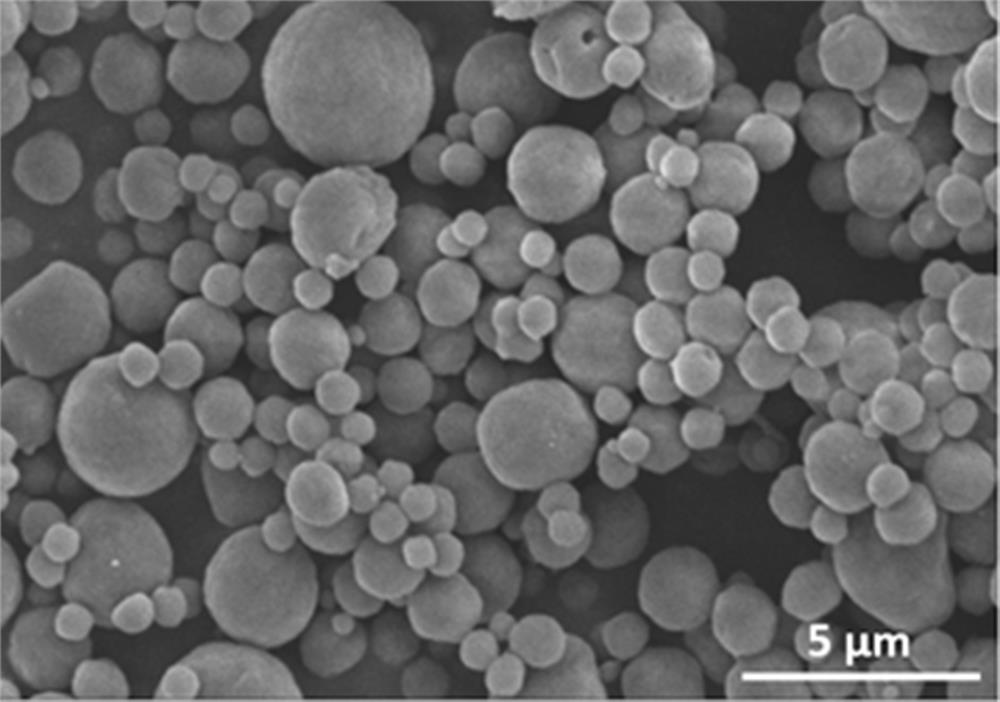

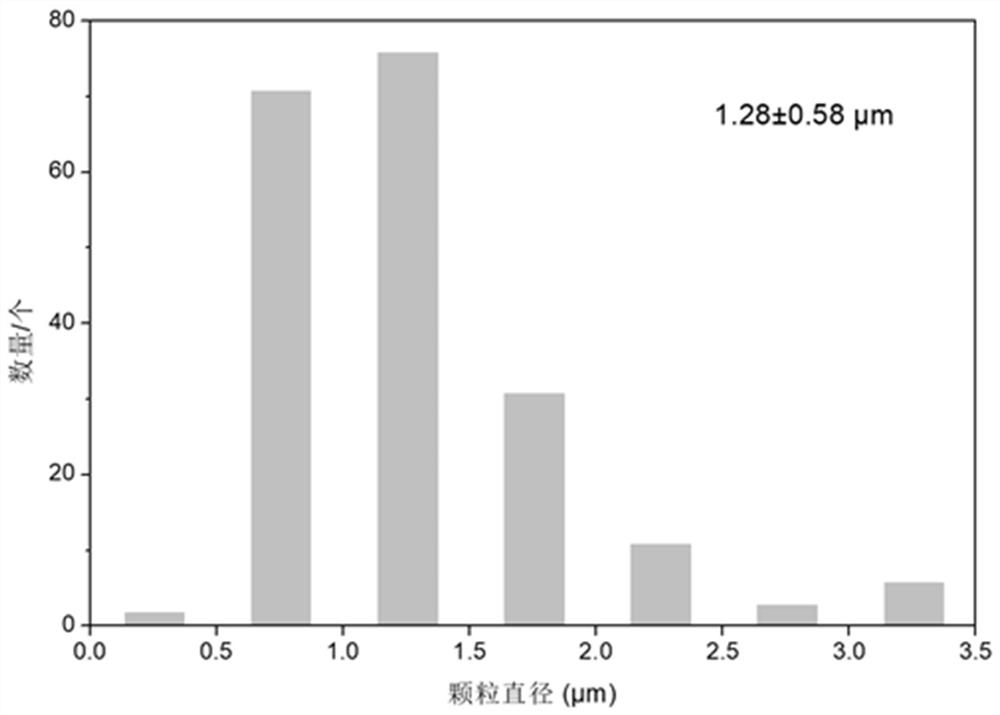

Image

Examples

Embodiment 1

[0060] The collagen stock solution used is prepared from pig Achilles tendon with a purity of 99.8%, a concentration of 8mg / mL, and an rpn value of triple helix structure integrity of 0.12;

[0061] Spray drying: the inlet air temperature is 60±1°C, the feed speed is 30rpm, the outlet air temperature is 50-58°C, and the obtained powder is collected.

Embodiment 2

[0069] The collagen stock solution used is prepared from bovine Achilles tendon with a purity of 99.8%, a concentration of 15 mg / mL, and an rpn value of triple helix structure integrity of 0.12;

[0070] Spray drying: inlet air temperature: the inlet air temperature is 50±1°C, the feed speed is 25 rpm, the outlet air temperature is 30-40°C, and the obtained powder is collected.

Embodiment 3

[0078] The collagen stock solution used was prepared from rat tail with a purity of 99.8%, a concentration of 20 mg / mL, and an rpn value of triple helix structure integrity of 0.12;

[0079] Spray drying: the inlet air temperature is 40±1°C, the feed speed is 18 rpm, the outlet air temperature is 20°C-30°C, the obtained powder is collected, and sterilized by irradiation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com