Method for extracting native natural collagen from animal skin or/and tendon

A technology of collagen and animal skin, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of long extraction time and low yield, so as to save extraction time, increase yield, and improve utilization efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

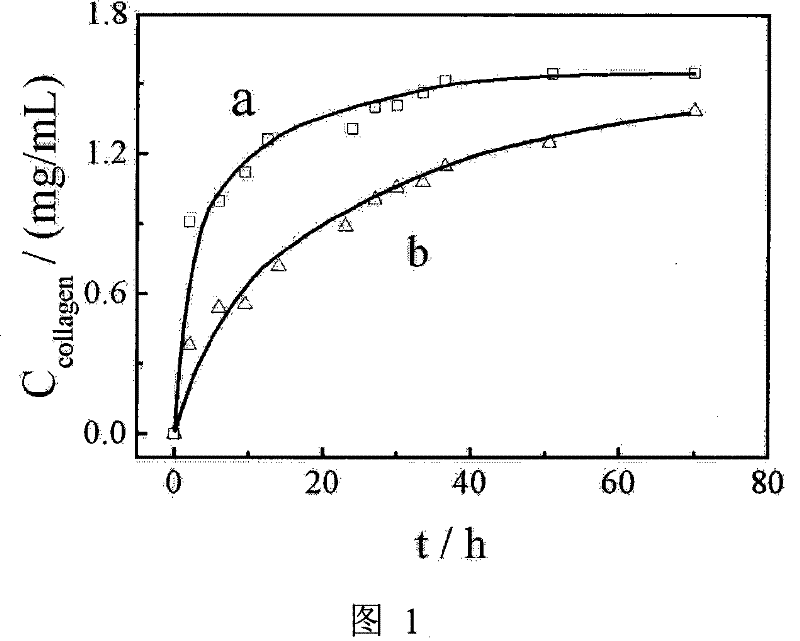

Image

Examples

Embodiment 1

[0028] (1) Raw material pretreatment: clean and fresh healthy pigskin is used as raw material. Remove the grease and impurities on the surface of the pigskin as much as possible, and then cut the raw materials into small pieces. After soaking in acetone for about 24hrs, take it out and dry it naturally, then crush the raw materials into crumbs with a pulverizer.

[0029] (2) Enzymolysis: Weigh 10 parts by weight of raw material scraps, add them to a reactor equipped with a stirrer and a thermometer, add 500 parts by weight of 0.5mol / L acetic acid solution, add 0.25 parts by weight of pepsin after soaking for about 1 hour, and then react The device is placed in an ultrasonic water bath with a power of 120W / 5g, and the stirrer is operated at about 20°C for about 24 hours for ultrasonic enzymolysis.

[0030] (3) Centrifugation: Dilute the enzymolysis solution 3 times with 0.5mol / L acetic acid solution and keep stirring. Centrifuge to remove the incomplete part of the enzymolysi...

Embodiment 2

[0035] (1) Raw material pretreatment: clean and fresh bovine Achilles tendon is used as raw material. Remove as much grease and impurities as possible from the surface of the Achilles tendon, then cut the ingredients into small pieces. After soaking in acetone for about 12hrs, take it out and dry it naturally, and then use a pulverizer to crush the raw materials into crumbs.

[0036] (2) Enzymolysis: Weigh 10 parts by weight of raw material scraps, add them to a reactor equipped with a stirrer and a thermometer, add 800 parts by weight of 0.5mol / L acetic acid solution, soak for about 1 hour, add 0.2 parts by weight of pepsin, and then react The device is placed in an ultrasonic water bath with a power of 100W / 5g, and the stirrer is operated at about 20°C for about 12 hours for ultrasonic enzymolysis.

[0037] (3) Centrifugation: Dilute the enzymolysis solution 5 times with 1mol / L acetic acid solution and keep stirring. Centrifuge to remove the incomplete part of the enzymoly...

Embodiment 3

[0042] (1) Raw material pretreatment: use clean and fresh sheepskin as raw material. Try to remove the grease and impurities on the surface of the raw material, and then cut the raw material into small pieces. After soaking in acetone for about 24hrs, take it out and dry it naturally, then crush the raw materials into crumbs with a pulverizer.

[0043] (2) Enzymolysis: Weigh 10 parts by weight of raw material scraps, add them to a reactor equipped with a stirrer and a thermometer, add 250 parts by weight of 1.0mol / L acetic acid solution, add 0.3 parts by weight of pepsin after soaking for about 1 hour, and then react The device is placed in an ultrasonic water bath with a power of 120W / 5g, and the stirrer is operated at about 25°C for about 12 hours for ultrasonic enzymolysis.

[0044] (3) Centrifugation: Dilute the enzymolysis solution 3 times with 1.0mol / L acetic acid solution and keep stirring. Centrifuge to remove the incomplete part of the enzymolysis solution to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com