In-situ-crossly-linked electrospun fibrous membrane dressing made from collangen I and preparation method of in-situ crosslinking electrospun fibrous membrane dressing

An electrospinning fiber, in-situ cross-linking technology, applied in fiber processing, plant fiber, animal fiber, etc., can solve the problems of difference and misunderstanding between collagen and gelatin, and achieve the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

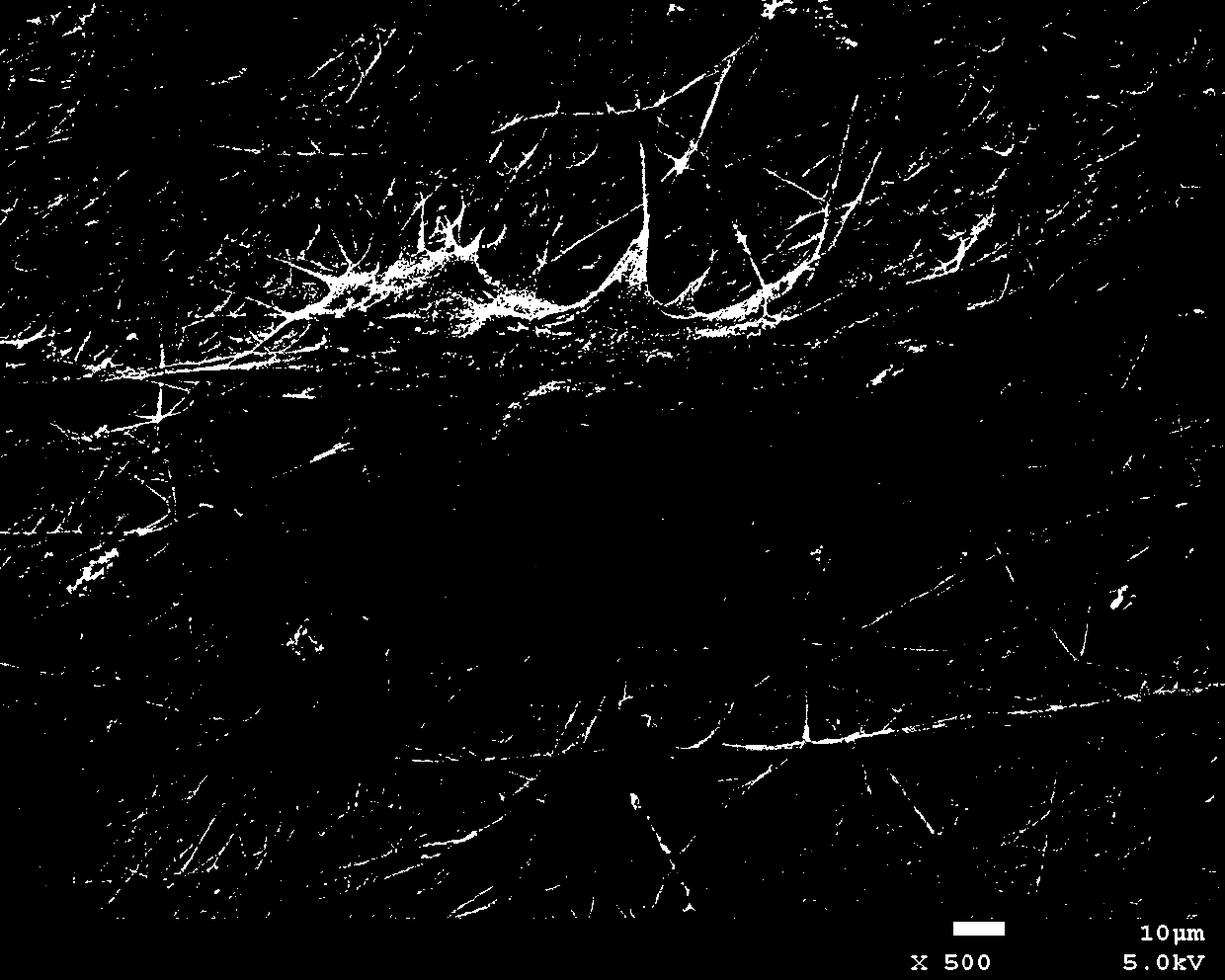

Image

Examples

Embodiment 1

[0038] (1) To prepare the collagen electrospinning component A solution, first dissolve LiCl in [EMIM][Ac] with a mass fraction of 0.1%, and then use this solvent system to dissolve cowhide type I collagen, where the collagen mass fraction is 5% , during the whole dissolution process, keep the temperature at 4°C, and the dissolution time is 24h;

[0039] (2) To prepare the cross-linking component B liquid, firstly, the commercially available oxidized sodium alginate was dialyzed, the molecular weight cut-off of the dialysis bag was 3500 Daltons, the dialysate was deionized water, and the dialyzing time was 3 days, after which it was dissolved In deionized water, prepared as a solution with a mass fraction of 3%, the dissolution time was 48 hours, and left to stand for defoaming;

[0040] (3) Mix Component A and Component B evenly at a volume ratio of 4:6. After ultrasonic defoaming, place them in the same injection device in the electrospinning device for electrospinning. The ...

Embodiment 2

[0044] (1) To prepare collagen electrospinning component A, firstly dissolve LiAc in [EMIM][Ac] with a mass fraction of 0.5%, and then use this solvent system to dissolve pigskin type I collagen, where the mass fraction of collagen is 9 %, during the whole dissolution process, keep the temperature at 4°C, the dissolution time is 24h, and stand for defoaming;

[0045] (2) To prepare the cross-linking component B liquid, firstly, the commercially available oxidized sodium alginate was dialyzed, the molecular weight cut-off of the dialysis bag was 5000 Daltons, the dialysate was deionized water, and the dialyzing time was 4 days. In deionized water, prepared as a solution with a mass fraction of 6%, the dissolution time was 48 hours, and ultrasonic defoaming;

[0046] (3) Component A and component B are ultrasonically degassed at a volume ratio of 5:5 and placed in an independent injection device in an electrospinning device for electrospinning. The positive high voltage is 20kv,...

Embodiment 3

[0050] (1) To prepare collagen electrospinning component A liquid, first LiClO 4 Dissolve in [EMIM][Ac] with a mass fraction of 1%, and then use this solvent system to dissolve bovine Achilles tendon type I collagen, wherein the collagen mass fraction is 15%, and keep the temperature at 4°C during the entire dissolution process. Dissolving time is 48h, stand still for defoaming;

[0051] (2) To prepare the cross-linking component B liquid, first, dialyze the commercially available oxidized sodium alginate, the molecular weight cut-off of the dialysis bag is 8000 Daltons, the dialysate is deionized water, and the dialyzing time is 3 days, then dissolve it In deionized water, prepared as a solution with a mass fraction of 13%, the dissolution time was 48h, and ultrasonic defoaming;

[0052] (3) Component A and component B are ultrasonically degassed at a volume ratio of 6:4 and then placed in an independent injection device in the electrospinning device for electrospinning. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com