Method for preparing laminated electrochromic polymer film capable of regulating and controlling full-color display

A polymer film and electrochromic technology, applied in the field of polymer materials, can solve the problems of poor processability and few colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing, but protection scope of the present invention is not limited to this:

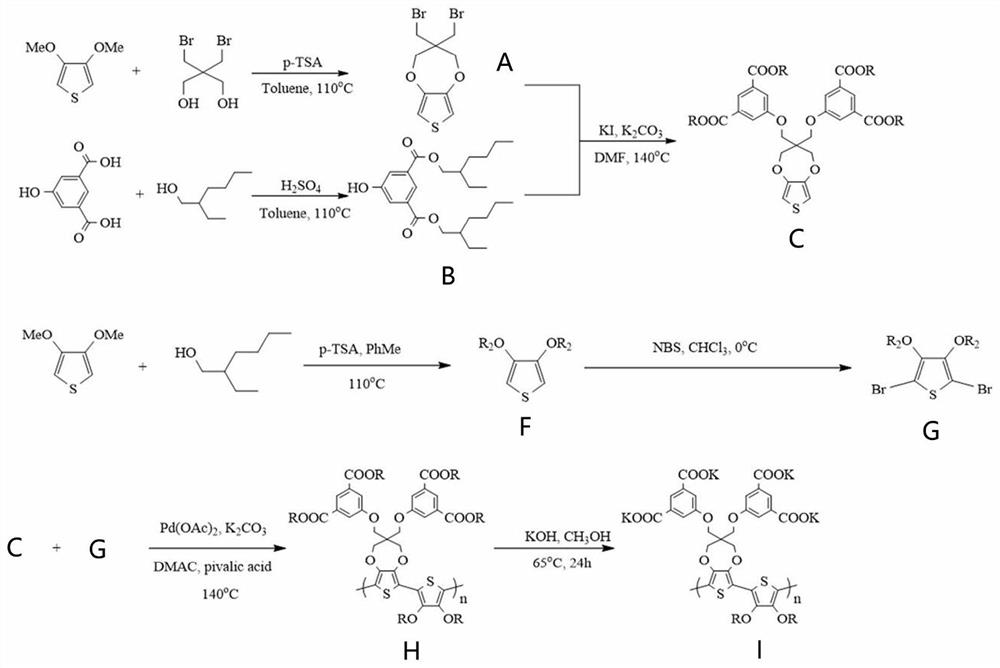

[0062] Such as figure 1 As shown, the preparation of water-soluble magenta electrochromic polymer comprises the following steps:

[0063]Step 1. Add 1.44g (10mmol) of 3,4-dimethoxythiophene, 5.24g (20mmol) of dibromoneopentyl glycol, 0.18g (1mmol) of p-toluenesulfonic acid, and 30mL of toluene into a 100mL two-necked flask in sequence , heated at 110 ° C for 16 hours, after the reaction, extracted three times with water and dichloromethane, collected the extract of the dichloromethane phase, concentrated and dehydrated with anhydrous sodium sulfate, purified by column chromatography, fixed on silica gel Phase, dichloromethane and petroleum ether as the mobile phase, the volume ratio of dichloromethane and petroleum ether is 1:3, the eluate containing the target compound is collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com